PUMPS & VALVES RESOURCES

-

For modern pipelines and pumps, noise and vibration behavior must be considered in system design. Learn how a wastewater pumping station in Greifswald, Germany reduced pump-induced pressure fluctuations by 90%, accompanied by lower vibration levels in the discharge line, with an innovative AI-enhanced damping system.

-

A water filtration treatment plant was built in 1950, pneumatic actuators were installed on all of the filter control valves. The pneumatic actuators were not always reliable. Air compressor problems limited the availability of the pneumatics to control the filter valves.

-

Discover how installing Beck electric actuators on the aeration blower control valves has improved process stability and plant operations for a South Florida treatment plant.

-

A water treatment plant was using conventional electric actuators on valves across the facility, including the modulating Filter Effluent applications. A history of actuator problems prompted plant personnel to consider replacements.

-

Read about one of the largest wastewater treatment plants in the world that recently finished a project for upgrading its sludge valve actuators.

-

As technology improves and becomes more accessible, outdated municipal wastewater systems are fast beginning to show their age. Today, water pumps come in a variety of designs that enable uses that previous generations could only have dreamed of.

-

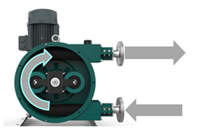

Peristaltic pumps have emerged as a revolutionary solution in industrial pumping, offering a myriad of benefits over traditional pump technologies. Fundamental to these pumps is a simple yet ingenious component: the hose. By using advanced hose designs, these pumps can significantly increase longevity and decrease operational costs. Let's explore how these innovative pumps are reshaping industrial pumping and driving efficiency across a range of applications.

-

When Kent County Water Authority faced the urgent replacement of a 94-year-old hydrant tied to a 1931 cast iron main, they were determined to maintain fire protection and avoid customer disruption.

-

Challenges associated with deploying smart water technologies include "Where do I begin?" and "Who do I use?". These questions can often be barriers to small and mid-sized utilities that have limited resources available to them and are already burdened with competing daily priorities.

-

AMERICAN is helping rebuild Puerto Rico’s vital water infrastructure after Hurricane Maria, supplying American-made products to strengthen resiliency for 3.5 million residents and millions of annual visitors.