DRINKING WATER FILTRATION RESOURCES

-

Both rural and urban water systems experience dissolved organic carbon (DOC) — a precursor to halogenated organic compounds like total trihalomethanes (TTHMs) and haloacetic acids (HAA5) — in source water. However, rural systems often struggle to find treatment options suited for smaller scale operations and budgets.

-

As water-scarce regions clamor for answers, developments in membrane anti-scaling bring desalination closer to viability.

-

The control of silica fouling in reverse osmosis systems is crucial for maintaining system performance efficiency and longevity. It prevents costly downtime and membrane damage. This article provides practical knowledge on silica scaling in RO systems, its challenges, and effective control strategies.

-

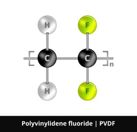

As Europe edges closer to regulating the production of PVDF membranes — key contributors to the toxic PFAS, 'forever chemicals' — the water industry finds itself at a critical crossroads.

-

Advantages include enhanced media bed life, reduced waste, minimized downtime, and improved overall system performance.

-

While pilot columns provide the most accurate estimations for predicting full-scale PFAS treatment performance by GAC or IX resin, they can be costly and time-consuming. Rapid small-scale column tests (RSSCTs) offer significant advantages over pilot columns, including less time, lower costs, less media, smaller sample volume, and faster data turnaround.

-

Per- and polyfluorinated substances (PFAS) continue to dominate the conversation as an emerging contaminant of concern due to their potential for adverse human health effects and continued regulation. This group of chemicals can be found in a wide variety of consumer products and drinking water.

-

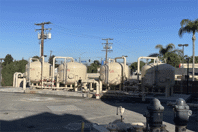

Serving California for more than 90 years, Golden State Water Company (GSWC) provides water service to more than 1 million customers in over 80 communities, including the City of Norwalk.

-

Zone 7 Water Agency is a water wholesaler in Northern California that serves more than a quarter million residents. Blending water from both surface and groundwater sources has enabled Zone 7 to address many emerging contaminant concerns over the past several years.