WATER MEMBRANES RESOURCES

-

Researchers have developed polyimide-based membranes for membrane distillation (MD) that overcome three persistent issues in membranes for water treatment and gas separations: the need for pore-forming chemicals that prevent recycling, performance degradation due to pore wetting and fouling, and the inherent trade-off between high water flux and selectivity.

-

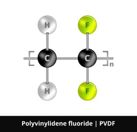

By classifying PVDF as a PFAS “forever chemical” and including it under the proposed restriction, the EU has introduced the prospect of a multi-billion-dollar technology shift. While the outcome will depend on the final derogation periods granted, the proposal creates a defined regulatory horizon for PVDF membranes and forces the global water industry to evaluate alternatives.

-

The business case for industrial water reuse has fundamentally shifted. Companies once evaluated these systems against environmental goals or regulatory compliance costs. Today, they're measuring them against operational risk and supply security — a calculation that increasingly favors reuse regardless of sustainability credentials.

-

Both rural and urban water systems experience dissolved organic carbon (DOC) — a precursor to halogenated organic compounds like total trihalomethanes (TTHMs) and haloacetic acids (HAA5) — in source water. However, rural systems often struggle to find treatment options suited for smaller scale operations and budgets.

-

As water-scarce regions clamor for answers, developments in membrane anti-scaling bring desalination closer to viability.

-

The control of silica fouling in reverse osmosis systems is crucial for maintaining system performance efficiency and longevity. It prevents costly downtime and membrane damage. This article provides practical knowledge on silica scaling in RO systems, its challenges, and effective control strategies.

-

As Europe edges closer to regulating the production of PVDF membranes — key contributors to the toxic PFAS, 'forever chemicals' — the water industry finds itself at a critical crossroads.

-

Discover how Aquapolo Ambiental tackled RO membrane biofouling with HOD™ UV technology, achieving 30-35% longer membrane life, reduced chemical use, and enhanced water reuse efficiency.

-

Read about how the installation of the HOD UV technology has been a viable non-chemical means for biological control and membrane protection for Trimble County.