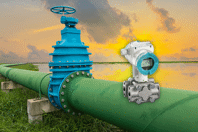

DRINKING WATER FLOW CONTROL AND MEASUREMENT RESOURCES

-

Discover how the implementation of pressure sensing technology has allowed the city of Monroe, North Carolina to gain greater insight into its distribution system and why main breaks were occurring.

-

The sole role of automatic water level controllers is to automatically maintain the reservoir or tank's water level within the range you want. These devices are comprised of a control unit with a pump or valve as per the build-up and sensors. You can find the sensors at different levels, which will help you trace the water level.

-

Discover what technologies were able to measure, monitor, and control for a city in northwest Greece, while also ensuring a safe and clean water supply.

-

A municipal water district had questioned the accuracy of their water meter readings and, after testing, they found that the billing amounts were too low. Discover the solution that they chose to provide reliable flow rate measurement.

-

Discover why clamp-on flow measurement provides a much more reliable and accurate reading compared to other methods.

-

A county water authority in the Northeast U.S. supplies over 40 million gallons per day to its 340,000 residential customers. In this case study, learn why they chose Siemens pressure transmitters.

-

A super-sized electromagnetic flowmeter produced by ABB is on its way to Saudi Arabia where it will help supply fresh water to the region as part of a desalination project.

-

It’s been more than two years since Aqua Pennsylvania began using an eye-opening technology, the AMERICAN Flow Control SEMPER Remote Pressure Monitor (RPM), to identify pressure transients and reduce main breaks and non-revenue water.

-

Biopharmaceutical processing is highly precise, and people must rely on various measuring devices to control costs, maintain quality, and avoid accidents. They often use flow meters to accomplish many of those aims. Here are some specific ways professionals working in pharmaceutical processing use these devices, making them so instrumental in successful outcomes.

-

Learn how water and wastewater utilities can use data to find operational efficiencies can both reduce energy costs and reduce carbon emissions.