Automatic Water Level Controllers: Everything You Should Know

By Amey Adsule

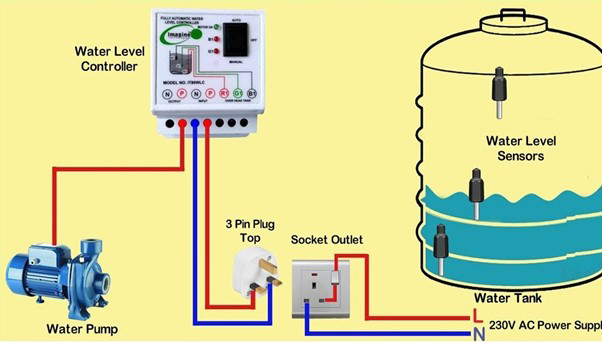

The sole role of automatic water level controllers is to automatically maintain the reservoir or tank's water level within the range you want. These devices are comprised of a control unit with a pump or valve as per the build-up and sensors. You can find the sensors at different levels, which will help you trace the water level.

How Does It Work?

A pressure switch has a preset option with beginning and ending pressure values. The pump starts automatically whenever the water pressure goes below the set level and off when it goes to the ultimate stopping pressure point.

More About Automatic Water Level Controllers

Automatic water level controllers continuously adjust the level of the water, turning the motor on and off as per the requirement to control water and energy wastage.

Water pumps are inseparable from fluid events; you can find them in residential water supply processes, HVAC systems, irrigation systems, power plants, industrial processes, and more. Controlling them is important for the addition of reliability, sustainability, and efficiency.

Let’s discuss the advantages, things to check, and working principles of four control methods for common pump types.

Variable Speed Control

Variable frequency drive (VFD) technology or frequency conversion is used to control different speed water pumps. Variable speed control arrests the pump motor speed while permitting it to perform as per the system's needs.

Working Principle of Variable Speed Control

If you check this VFD controller, you will find it similar to any microcomputer, capable of handling multiple signals simultaneously. The water pump's on and off setting completely depends upon pressure sensing. Whenever the frequency decreases below 50hz, the motor functions slowly. The pressure is stabilized by altering the frequency value. For applications where water demand is high, it runs quicker, and vice versa for low demand. When one is not using water, it stops automatically.

Mix the sensor with the module of constant pressure water supply and frequent conversion speed controller so that the water pump works according to the need. This option might look expensive compared to others, but the advantage it adds to your water experience while saving energy and introducing efficiency to the pump is huge.

You will find them in public places or real estate settings for controlling drainage and water supply.

Pressure And Flow Integrated Control

With this device, often found in water booster pumps, the electronic pressure controls the flow switch and the pressure sensor entirely.

Working Principle of Pressure and Flow Integrated Control

As the tap opens, the pump starts and stops the water flow when you close it due to dual control. It is the right substitute for the typical traditional pump, which has a check valve, pressure switch, and pressure tank. It stops working when there is no or less water, so it doesn't get spoiled due to dry running.

The pump in a regular household often stops working due to dry running, and you can stop it with this device. It is not advised for use in high-pressure applications where several taps run together and the water pressure needs to be changed too frequently.

Pressure Control

It also works on the same phenomenon and starts when it finds the water pressure dropping and stops when it rises. The pressure switch is solely responsible for controlling the pump throughout following this pattern.

Working Principle of Pressure Control

The pressure switch in it is designed in a way that it can easily start and stop the pressure value. The pump turns on on its own whenever the pressure of the water falls below the set pressure and goes off when the water is full. You will find the water pressure changing throughout the day, and a normal, unstable pump is not what we advise. The unwanted on-and-off options may not be sufficient in the long term; you need more than this.

Flow Control

Controlling the flow is the oldest of control methods, whereby the pump starts and stops automatically. And, yes, there is a flow switch to do it.

Working Principle of Flow Control

This switch adjusts the flow automatically, stopping and starting the pump based entirely on the flow rate. It helps to manage the stable water pump flow rate and also controls energy wastage that might occur if you run the pump when not in use. It also reduces water wastage and allows the pump to sustain for a long.

Although a flow switch can be advisable to control the water pump operations in some cases, especially when you cannot avoid a consistent flow rate, it is unfortunately inaccurate. They are too sensitive towards flow rate changes. You can use them in conjunctions and when paired with other devices only. Use them along with level sensors and pressure switches for the results you are looking for.

Wrapping Up

While choosing the right pump control method, understand what you need for your application. Check the pump type, pressure, and volume of the water, the set budget, and above all, the water sources.

Reference: https://www.custommarketinsights.com/report/automatic-water-level-controller-market/