NUTRIENT REMOVAL RESOURCES

-

Read about three of the most pressing wastewater challenges utilities face today and how Stratmoor Hills, Key West Resort Utilities, and Beijing Water Group are using advanced treatment and reuse to overcome them.

-

Water scarcity poses unique challenges to KW Resort Utilities Corp. (KWRU), the utility firm that provides wastewater management, wastewater recovery, and wastewater treatment in the region. KWRU began operation in the late 1960s and has worked hard over the decades to keep up with wastewater needs as population and tourism have boomed, spurred by land reclamation and development.

-

This paper presents a comprehensive overview of technologies for phosphorus removal and recovery, including chemical and biological processes, ballasted clarification, filtration, and nutrient recovery.

-

Technology like advanced process control systems can streamline operations, create opportunities to lower costs and emissions, and ensure effluent quality meets the highest standards. Research also indicates that implementing an appropriate control strategy can help reduce N2O emissions.

-

Learn how a beverage plant cut its annual Reverse Osmosis reject water hauling volume by 50%. Real-time Total Nitrogen monitoring reduced compliance costs by $350,000 and eliminated discharge penalty risk.

-

A densified sludge process can improve wastewater treatment by promoting larger, denser sludge particles. This enhances settling, improves nutrient removal, and increases treatment capacity.

-

Large wastewater facilities are designed to remove physical, chemical, and biological contaminants from domestic wastewater or industrial effluent, producing treated water that is safe to discharge into rivers. But they’re expensive and energy-intensive. They’re also difficult to maintain in rural areas where local government doesn’t get much revenue.

-

Finding the right wastewater treatment solution can be tricky, especially for smaller operations. Modular small-scale wastewater treatment systems offer practical solutions for various settings, from hotels and resorts to real estate developments and remote communities. How do you pick the right system? Let's explore these systems and their importance.

-

Entrusted HOA and lake board members seek the best path forward to preserve the lake lifestyle in the face of algal blooms, health risks, lake closures, unpleasant odors, and falling property values.

-

In this case study, learn about a city that worked with ChartWater™ to provide emergency, supplemental oxygenation using BlueInGreen’s supersaturated dissolved oxygen (SDOX®) technology.

-

The Wolcott Wastewater Treatment Plant in Kansas City chose the AquaNereda technology for its capacity and cost benefits. The system improved nutrient removal and met permit requirements.

-

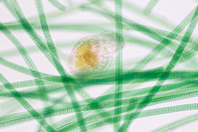

Pollution and microplastics float down waterways that treatment plants have to manage. Alongside these contaminants are drifting flowers that clear aquatic habitats. Recent research shows they could be an organic method for removing phosphorus and nitrogen.

-

Stricter effluent regulatory standards and a continued focus on sustainability by industrial companies demands innovative treatment solutions. These solutions include innovative modular industrial wastewater treatment plants that assist manufacturers in meeting these treatment standards in the most environmentally friendly way.

-

Just like humans have the freedom to make life choices, cyanobacteria also possess their own unique survival strategies. Groundbreaking research conducted by Griffith University's Australian Rivers Institute unveils the fascinating world of cyanobacteria and how they employ phosphorus storage to thrive.

-

Read about three of the most pressing wastewater challenges utilities face today and how Stratmoor Hills, Key West Resort Utilities, and Beijing Water Group are using advanced treatment and reuse to overcome them.

-

Water scarcity poses unique challenges to KW Resort Utilities Corp. (KWRU), the utility firm that provides wastewater management, wastewater recovery, and wastewater treatment in the region. KWRU began operation in the late 1960s and has worked hard over the decades to keep up with wastewater needs as population and tourism have boomed, spurred by land reclamation and development.

-

This paper presents a comprehensive overview of technologies for phosphorus removal and recovery, including chemical and biological processes, ballasted clarification, filtration, and nutrient recovery.

-

Technology like advanced process control systems can streamline operations, create opportunities to lower costs and emissions, and ensure effluent quality meets the highest standards. Research also indicates that implementing an appropriate control strategy can help reduce N2O emissions.

-

Learn how a beverage plant cut its annual Reverse Osmosis reject water hauling volume by 50%. Real-time Total Nitrogen monitoring reduced compliance costs by $350,000 and eliminated discharge penalty risk.