FLUSHABLES RESOURCES

-

The Vassar wastewater treatment plant (WWTP) in Michigan, confronted persistent challenges from non-dissolvable solids by adopted Duperon's Dual Auger System (DAS) to address these issues effectively.

-

It is a known issue that wastewater infrastructure is aging and is in need of significant investment to upgrade or replace systems to operate safely. Age is not the only factor driving system replacements. Wastewater itself has changed, which means what flows through collection systems and into treatment plants is different than what it was 50 years ago. At home, lower-flow toilets translate to less water to move flushed solids.

-

When the Kearney, MO wastewater treatment plant began plans to upgrade its headworks they choose JWC Environmental’s Brushless Finescreen Monster to replace its old coarse screen.

-

With Xylem's Flygt Concertor solution, Rice University now avoids clogs and callouts caused by grease and debris, as well as costly recurring equipment replacement.

-

Learn about the innovative pumping technology that eliminates clogging, saving time and money for an Oregon utility.

-

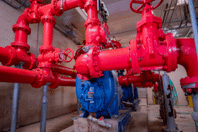

The rise in the use of disposable wipes and other non-dispersible debris is driving the need for more efficient handling of solids in pumps at municipal lift stations and wastewater treatment plant headworks.

-

Explore how a wastewater treatment plant in Pottsville, Pennsylvania, addressed clogging and maintenance issues with the Duperon Dual Auger System.

-

The U.S. has more 148,000 drinking water systems which distribute 39 billion gallons of potable water to homes and businesses nationwide. For those who work in the drinking water and wastewater treatment industry, the size, scope, and challenges to the country’s water infrastructure are well known.

-

The Drake Pump Station, located in Saginaw, Michigan experienced chronic pump maintenance due to flushable wipes. Although the dry pit pump station represented only 0.1 million gallons per day (mgd) of flow in the city’s collection network, it required a substantial amount of servicing – up to three times a week. This consisted of two operators spending four hours manually removing rags in a confined space entry to clean out the clogged pump. It was a dirty, unplanned, and time-consuming task.

-

Wastewater treatment plant operators have dealt with clogging problems at their plants and pump stations for decades, but the meteoric rise in the use of disposable wipes and other non-dispersible products has accelerated the problem to epidemic proportions.