RESOURCES FOR THE POWER GENERATION INDUSTRY

-

As global climate goals and the environmental impact of hydroelectric systems draw increased attention, the conversation for energy leaders and water resource professionals has shifted from expansion to optimization, where smarter infrastructure and adaptive strategies must work together to reduce harm without compromising output.

-

Orange County Water District is combining operational flexibility with environmental stewardship by participating in demand response, earning millions in payments while maintaining their commitment to delivering clean, reliable water.

-

The idea of utilizing water as a fuel source has been speculated by scientists, innovators, and researchers from all over the globe, envisioning a world where renewable, green energy can power the planet.

-

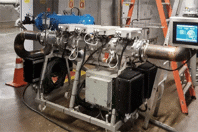

Read about an extensive study that was carried out to evaluate the ability of the HOD UV system to control biofouling in the Governador José Richa Power Plant.

-

Wastewater ponds may seem an unlikely place to look for solutions an electricity security crisis. But their underutilized surfaces could help tackle two problems at once — high power prices and algal growth.

-

A power plant in Pinghu, Zhejiang Province in China needed to replace the use of chemical biocides and protect boiler feed make-up water from anaerobic and aerobic bacterial growth and associated biofouling.

-

A West coast power plant needed an immediate solution to clean its cooling tower that was fast, cost effective, and did not require removal and manual cleaning of the tower's fill material.

-

Plant Bowen, a coal-fired power station in Georgia, successfully implemented Atlantium's HOD UV technology to eliminate microbial growth and improve the performance of their reverse osmosis system. The HOD UV system removed chlorine, reduced maintenance costs, and extended the lifespan of membranes.

-

Using earth-friendly energy and conserving water supports the fight against climate change and preserves our freshwater reserves.

-

Water stress, whether caused by drought, access limitation, or contamination, has been increasingly detrimental for an ever-growing range of industries. Recently, a report by CDP, in collaboration with Planet Tracker, shed light on the significant impact of water insecurity on the financial performance of more than 4,000 companies. Of particular note are those companies in energy or energy-adjacent sectors.