WASTEWATER FILTRATION RESOURCES

-

A water filtration treatment plant was built in 1950, pneumatic actuators were installed on all of the filter control valves. The pneumatic actuators were not always reliable. Air compressor problems limited the availability of the pneumatics to control the filter valves.

-

This paper presents a comprehensive overview of technologies for phosphorus removal and recovery, including chemical and biological processes, ballasted clarification, filtration, and nutrient recovery.

-

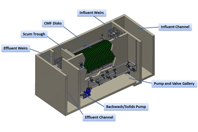

This application note from Aqua-Aerobic Systems highlights the effectiveness of the AquaStorm® Cloth Media Filter as a flexible, compact, and highly efficient solution for Combined Sewer Overflow (CSO) and Sanitary Sewer Overflow (SSO) events.

-

Discover why, rather than installing a costly stormwater storage tank, the City of Rushville partnered with Aqua-Aerobic Systems to pilot the AquaStorm Cloth Media Filter.

-

For years, conventional activated sludge (CAS) has been the default in wastewater treatment. But the industry is changing.

-

A power plant in Pinghu, Zhejiang Province in China needed to replace the use of chemical biocides and protect boiler feed make-up water from anaerobic and aerobic bacterial growth and associated biofouling.

-

The BluBox MBR system was installed in a master-planned community, meeting water quality standards and providing a cost-effective solution. M|MBR Systems played a crucial role in plant operations and supported the community's rapid growth.

-

This white paper will explore advanced, sustainable wastewater management systems that align with your business's growth trajectories and emergent needs.

-

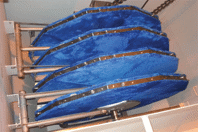

This application profile focuses on two test sites with different treatment requirements and describes how Aqua-Aerobic Systems’ OptiFiber® pile cloth media filtration was used at both sites to address the removal of harmful constituents from refinery wastewater.

-

Learn about filtering microplastics from industrial wastewater prior to discharge, and how this is one way to effectively reduce the volume of this waste material from entering our surface water.