PUMPS AND DRIVES RESOURCES

-

For modern pipelines and pumps, noise and vibration behavior must be considered in system design. Learn how a wastewater pumping station in Greifswald, Germany reduced pump-induced pressure fluctuations by 90%, accompanied by lower vibration levels in the discharge line, with an innovative AI-enhanced damping system.

-

Pumps are power-hungry and thus expensive to run, but San Jose Water shows how data-driven technologies and strategies can bring the cost down for utilities.

-

Every day in the U.S., an estimated 6 billion gallons of water is lost due to leaks in our water distribution systems. That’s enough to meet the needs of 60 million people—and it’s not just your water that’s being lost.

-

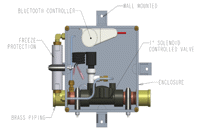

Challenges associated with deploying smart water technologies include "Where do I begin?" and "Who do I use?". These questions can often be barriers to small and mid-sized utilities that have limited resources available to them and are already burdened with competing daily priorities.

-

For aging pump systems, a full replacement is not always practical or cost-effective. In such cases, retrofitting offers a compelling alternative, breathing new life into existing infrastructure.

-

Installing or upgrading high-efficiency motors in water management reduces energy consumption and emissions throughout the water management process, from pumping stations to water treatment plants and irrigation systems.

-

Utilities can leverage advanced technologies to make monitoring and maintenance easier for operators to execute with fewer advanced skills, while reducing manpower and increasing the life of equipment.

-

Explore the parallels between water systems in buildings and water utilities, and the need for property owners to adopt water quality management practices, such as time-based flushing, to maintain safe water conditions for occupants.