Rural Water Treatment Plant Reduces TTHMs And HAA5 With Ion Exchange

By Russ Swerdfeger and Andrew Dugan

The pristine waters of Lake Christina in northeastern Alberta, Canada, serve as a recreational attraction and water source for Conklin, a town of 250 residents and one of 11 Indigenous and rural communities in the Regional Municipality of Wood Buffalo. For years, Conklin’s water didn’t need dissolved organic carbon (DOC) treatment, but its numbers recently crept up to exceed the Guidelines for Canadian Drinking Water Quality.

DOC comes from the natural organic matter found in rivers, streams, and groundwater. It’s a precursor to halogenated organic compounds like total trihalomethanes (TTHMs) and haloacetic acids (HAA5), which occur when DOC reacts with chlorine-based water disinfectants. Canadian water plants are required to monitor for TTHMs and HAA5 because they have been shown to cause cancer and reproductive harm.

Both rural and urban water systems experience DOC in source water. However, rural systems often struggle to find treatment options suited for smaller scale operations and budgets.

Steven Meunier, foreman of operations for water treatment at the Regional Municipality of Wood Buffalo, tried treating DOC with a conventional coagulation treatment system of potassium permanganate, soda ash, and other chemicals, but the system still struggled to remove DOC effectively enough to minimize disinfection byproduct formation upon chlorination. Due to elevated DOC concentrations, the Conklin water treatment plant was sometimes unable to meet federal water guidelines for trihalomethanes and haloacetic acids, 100 and 80 parts per billion, respectively.

As DOC levels continued to rise, Meunier looked for newer treatment technologies, while also trying various solutions. “We have a big reservoir and a small population. We tried lowering contact time, aeration, as well as using different chemicals.”

The Search

At a regional conference in Western Canada, Meunier met with vendors, manufacturers' reps, and fellow operators to find a solution to his DOC problem. He learned how some plants had DOC removal success with ion exchange (IX) resin systems, specifically a fluidized bed process using MIEX® resin. So, with the support of the Regional Municipality management team, Meunier arranged for a four-week pilot study of IX technology at the Conklin water treatment plant.

Staff conducted multiple loading tests to determine the optimum treatment rate for their source water, selecting flow rates based on the treatment goals, economic feasibility, and diminishing DOC removal efficiency.

The pilot study showed immediate promise with Ixom Watercare’s MIEX Mini system, which comes specifically designed for small water treatment plants using a small-particle resin specifically designed for fluidized bed operation to reduce DOC levels and resulting disinfectant byproduct formation that occurs during chlorination.

How It Works

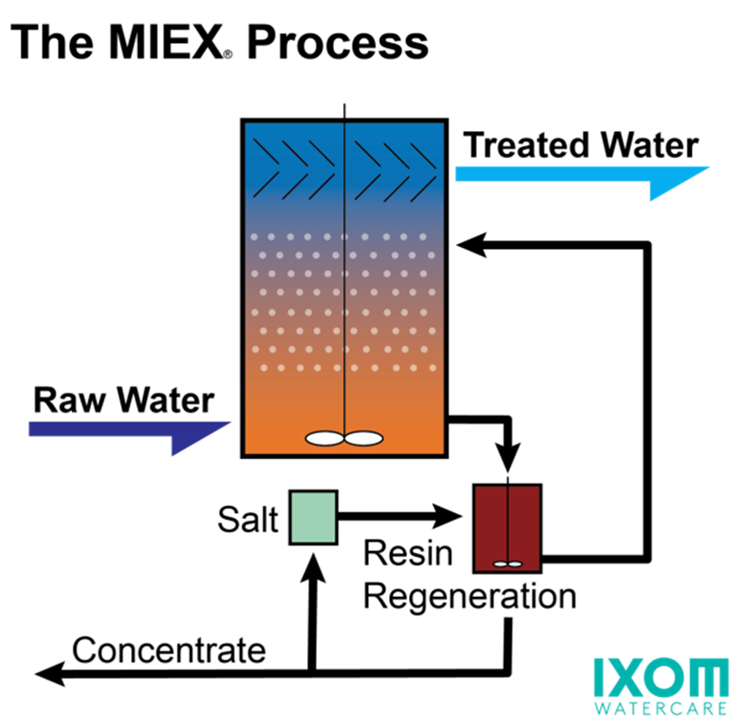

The resin beads are manufactured to be much smaller than conventional IX resins, providing four to five times the surface area to enable rapid exchange kinetics, which are highly selective for charged DOC. When the resin encounters source water, negatively charged organics are removed from the water by exchanging with a chloride ion on active sites of the resin surface. The magnetic properties of the IX beads allow them to agglomerate and settle rapidly or fluidize at high hydraulic loading rates.

Raw water is fed to the base of the reactor vessel in an up-flow path. Then, inclined plate settlers at the top of the reactor vessel assist with resin/water separation. Treated effluent overflows into collection launders and enters the conventional water treatment process. After a predefined volume of water has been treated, flow stops, water is drained from the vessel, and a brine solution is introduced in a down-flow path through the resin bed, regenerating the resin for further treatment.

Coagulants are left to remove the remaining, larger non-polar constituents, thereby decreasing coagulant dose and yielding a denser floc through minimized charge repulsions. The pretreatment IX step has also been proven to cut the consumption of flocculant aids, polymers, and pH adjustment chemical demand.

Less Chem, More Compliance

“The major adjustment was dropping our coagulant use quite a lot,” said Meunier. “The pilot study alluded to a 50% drop. So we were happily surprised when the full-scale solution dropped coagulant use by 75%.”

The reduction in coagulant reduces operating costs and sludge volumes generated by chemical additions, as well as increases filter efficiency due to less frequent backwashing. Meunier also noted that soda ash and hypochlorite use dropped by 50%. Additionally, UV transmission increases with the IX addition to the process train, improving UV disinfection and reducing UV energy demand.

“Based on our research and pilot, I was optimistic. Based on the results, I’m more than pleasantly happy about the decreased chemical use, and the operators all like it. There’s not much day-to-day maintenance; it’s not adding much work.”

More To Come

Conklin is one of four communities in the area, and each will also eventually need DOC treatment. Due to the success at Conklin WTP, the Regional Municipality of Wood Buffalo has initiated the design process to install another ion exchange system to tackle DOC at its Fort McKay water plant.

“It’s a simple system to run and integrates well with our treatment process. Fort McKay is a membrane plant, so I’m interested to see how the IX system benefits that treatment system in terms of coagulant consumption, backwashing frequency, and membrane life.”

Russ Swerdfeger is the head of marketing at Ixom Watercare. He's been in water and wastewater technology business for over 23 years, holding roles in process engineering, product management, sales, and marketing. He has worked at USFilter, Evoqua, and DuPont Water Solutions prior to joining Ixom. He can be contacted at russ.swerdfeger@ixom.com.

Russ Swerdfeger is the head of marketing at Ixom Watercare. He's been in water and wastewater technology business for over 23 years, holding roles in process engineering, product management, sales, and marketing. He has worked at USFilter, Evoqua, and DuPont Water Solutions prior to joining Ixom. He can be contacted at russ.swerdfeger@ixom.com.

Andrew Dugan runs WaterWrites, a utility-focused copywriting agency. He helps technology companies, engineering firms, and utilities communicate their work. He actively volunteers with the Water Environment Federation and is the editor of Rocky Mountain Water Magazine. He can be reached at Andrew.Dugan@waterwrites.co.

Andrew Dugan runs WaterWrites, a utility-focused copywriting agency. He helps technology companies, engineering firms, and utilities communicate their work. He actively volunteers with the Water Environment Federation and is the editor of Rocky Mountain Water Magazine. He can be reached at Andrew.Dugan@waterwrites.co.