The Benefits Of Pretreatment Prior To Bulk Media Filtration Of PFAS

By Jim Weidler, MYCELX Technologies Corporation

Advantages include enhanced media bed life, reduced waste, minimized downtime, and improved overall system performance.

Per- and polyfluoroalkyl substances (PFAS) have emerged as persistent environmental contaminants that pose a significant threat to human health. Effective removal from water sources is crucial, with adsorption via bulk media like granular activated carbon (GAC) and ion exchange resins (IER) being the primary methods. However, co-contaminants such as suspended solids, colloidal species, organic compounds, metals, and heavy organics like oil and grease can reduce the effectiveness of these media.

Pretreatment using cartridge filters prior to bulk media in the removal of PFAS is effective across a wide range of water sources, including stormwater, groundwater, surface water, and wastewater. The primary function of cartridge filters is to enhance the overall performance of PFAS treatment systems.

Challenges With Traditional Filtration Methods

Traditional filtration methods, such as GAC and IER, often struggle with frequent media replacement, incomplete PFAS removal, and high operational costs — issues largely attributed to the presence of co-contaminants. By providing broad-spectrum co-contaminant removal, cartridge filtration enhances the overall water treatment process, making it the logical choice for pretreatment in PFAS remediation systems.

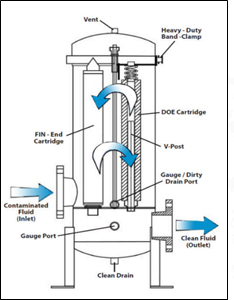

Operational Process And Benefits

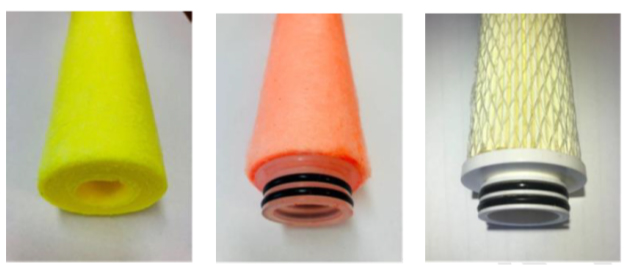

A variety of cartridge filter types (Figure 2) are available depending on the targeted contaminants, including PFAS compounds. These filters include Solids Treat Particle Removal (ST), Hydrocarbon Removal Matrix (HRM), Emulsion Breaker (EB), Pleat Treat Particle Removal (PT), and PFAS Removal (EB3.0). Each type is treated with a proprietary patented polymer chemistry known as “MYCELX,” which is non-toxic, non-leaching, hydrophobic, and safe for use in potable water applications.

Figure 2. Cartridge Filters (Type HRM, EB and EB3.0)

Advantages Of Cartridge Filtration

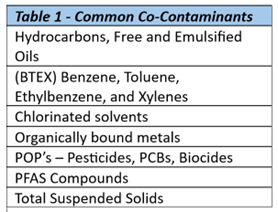

One of the key advantages of utilizing cartridge filters is their ability to remove a wide range of common co-contaminants (Table 1). This broad-spectrum removal is crucial in real-world applications where water matrices are often laden with various pollutants. The inclusion of cartridge filters in a treatment system provides a more sustainable and cost-effective solution by eliminating co-contaminants, preventing competitive adsorption, and reducing media fouling. This leads to extended media bed life, reduced frequency of media changeouts, lower overall operational expenses (OPEX), and decreased downtime.

One of the key advantages of utilizing cartridge filters is their ability to remove a wide range of common co-contaminants (Table 1). This broad-spectrum removal is crucial in real-world applications where water matrices are often laden with various pollutants. The inclusion of cartridge filters in a treatment system provides a more sustainable and cost-effective solution by eliminating co-contaminants, preventing competitive adsorption, and reducing media fouling. This leads to extended media bed life, reduced frequency of media changeouts, lower overall operational expenses (OPEX), and decreased downtime.

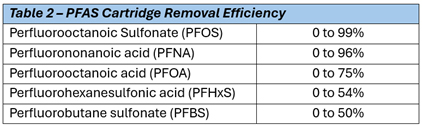

PFAS Targeting And Removal

PFAS specialty cartridge filters are constructed from advanced materials designed to target PFAS contaminants (Table 2). The specialized media, infused with MYCELX, adsorbs PFAS chemicals from the water, effectively removing them. Regular monitoring and timely replacement of the cartridges are necessary to maintain optimal PFAS removal efficiency.

Conclusion

Cartridge filters offer a unique, cost-effective solution for the removal of a wide range of contaminants, including PFAS. They should be considered an essential pretreatment step before bulk media filtration. The key benefits include extended media bed life due to broad-spectrum contaminant removal, minimal waste disposal, reduced downtime, and the reduction or elimination of backwashing requirements.