INDUSTRIAL WATER AND WASTEWATER TREATMENT

From Compliance To Circularity: Rethinking Chromium Management In Chrome Tanning

From Compliance To Circularity: Rethinking Chromium Management In Chrome Tanning

In an industrial landscape increasingly shaped by lifecycle accountability, material traceability, and rising disposal costs, chromium recovery is not merely a technical alternative — it is a strategic upgrade, where wastewater can become a resource stream.

WATER AND WASTEWATER SOLUTIONS FOR THE OIL AND GAS INDUSTRY

-

Refinery Expands Production While Meeting Discharge Standards Quality

Petron Bataan Refinery wanted to expand production to process 180 thousand barrels of crude oil per day while changing its feedstock from Arab Light to less costly heavy and sour crudes.

-

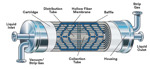

Inside The Technology: 3M Liqui-Cel Membrane Contactors

While dissolved gas can give beverages distinctive flavors and fizz, it can also corrode boiler equipment and cause problems in microelectronics. With 3M’s advanced gas transfer membrane technology, you have the power to control dissolved gases with precision. Dive in to learn the ins and outs of 3M Liqui-Cel technology.

-

FEDI Solution For Sohar Refinery Project

Orpic (Oman Oil Refineries and Petroleum Industries Company) required a thermal seawater desalination solution as part of its Sohar refinery improvement project to ensure an uninterrupted supply of fresh feed water to for its boilers.

-

EPA And Canadian Researchers Partner To Ensure Effective Responses To Oil Spills

The U.S.-Canada border is the world’s longest shared border and includes four of the five Great Lakes, many rivers, additional lakes, major airsheds and migratory routes for wildlife species. In addition, there are many Native American Tribes and First Nations residents whose culture extends across the border.

-

Saving Oil And Gas: Improving Profit Margins In Down Times With Innovative Water Management

With oil prices depressed, exploration and production companies unearth the money-saving opportunities in water management planning.

WATER AND WASTEWATER SOLUTIONS FOR THE FOOD AND BEVERAGE INDUSTRY

-

Inside The Technology: 3M Liqui-Cel Membrane Contactors

While dissolved gas can give beverages distinctive flavors and fizz, it can also corrode boiler equipment and cause problems in microelectronics. With 3M’s advanced gas transfer membrane technology, you have the power to control dissolved gases with precision. Dive in to learn the ins and outs of 3M Liqui-Cel technology.

-

Microbial Control In Cheese Making

Microbial contamination of food and beverage products is a potentially catastrophic occurrence resulting in foodborne illness or food spoilage. The same nutritive properties that render cheese and dairy products such a valuable food also provide an ideal growth medium for microbes if contamination occurs.

-

Seaboard Triumph Foods

Learn how Seaboard Triumph Foods replaced ineffective hydrogen peroxide treatment with SDOX technology, resulting in cost savings, improved sewer system, and enhanced odor control.

-

How Can The Food And Beverage Industry Reduce Its Water Usage?

Food and beverage production and processing consume massive amounts of water — both in products and as an essential material for various cleaning, cooling, and utility purposes. As climate change and drought threaten existing water sources, businesses and consumers are paying more attention to how industry at large uses it.

-

Feds Take Steps To Regulate Water For Food

Due to new rules proposed by the FDA, monitoring services and new pumps will likely be shopping-list items for food processors.

WATER AND WASTEWATER SOLUTIONS FOR THE POWER GENERATION INDUSTRY

-

The Key To Accurate Waste Gas Flow Measurement

Wastewater treatment facilities have a tremendous opportunity to utilize the biogas they generate to lower energy costs and minimize odors. However, the practice isn’t as widespread as it could be, as the precision gas flow and methane content readings required to optimize the process often clash with the misconception that biogas is messy and difficult to measure reliably. With the proper equipment, it is possible to accurately measure biogas to cut emissions and reduce or eliminate the energy bill.

-

Inside The Technology: 3M Liqui-Cel Membrane Contactors

While dissolved gas can give beverages distinctive flavors and fizz, it can also corrode boiler equipment and cause problems in microelectronics. With 3M’s advanced gas transfer membrane technology, you have the power to control dissolved gases with precision. Dive in to learn the ins and outs of 3M Liqui-Cel technology.

-

Desalination And Power Plants—An Ideal Partnership?

A partnership between power and desalination plants may be the solution to drinking water scarcity. Researchers are working on a new system that can create potable water using a low-temperature desalination process powered by waste heat from a waterless power plant cooling system.

-

City Of St. Cloud Relies On Thermal Flow Meters For Digester Biofuel Co-Gen Power Process

The City of St. Cloud, Minnesota, straddles the Mississippi River near the center of the state a little more than 65 miles north of the twin cities of Minneapolis-St. Paul. The city’s forward thinking staff began looking for sustainable green energy solutions in 2003. After planning and initiating a series of projects over several years, the site is today producing renewable energy with a 20 kW rooftop solar array, a 220 kW solar array and biofuels electricity generation.

-

Stormwater: A Valuable Resource For Power Plants?

Stormwater is often thought of as a burden. Too much of it can overwhelm wastewater treatment facilities, flood communities, and lead to the pollution of lakes and rivers. There is debate on who’s in charge of it and how it should be managed. Several communities have invested millions, and some even billions, trying to control stormwater. Even chicken farmers have issues with stormwater.

WATER AND WASTEWATER SOLUTIONS FOR INDUSTRY

-

On-site Leachate Treatment Systems Reduce Cost And Environmental Risk

Traditionally, landfill leachate has been hauled or pumped to publicly owned treatment works (POTWs) or other off-site treatment facilities for disposal.

-

Refinery Expands Production While Meeting Discharge Standards Quality

Petron Bataan Refinery wanted to expand production to process 180 thousand barrels of crude oil per day while changing its feedstock from Arab Light to less costly heavy and sour crudes.

-

Fluence Aerators Improve Lagoon Aeration at Recycled Paper Plant

Pronal, a recycled paper plant, produces craft paper. The plant produces an average flow of 14,000 m3/day (3.7 MGD) of wastewater with high contents of Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD) and Total Suspended Solids (TSS).

-

How Do We Solve The Problem Of Agricultural Nutrient Runoff?

Agricultural runoff from Midwestern farms is a major contributor to a vast “dead zone” in the Gulf of Mexico. Nitrogen, phosphorous and other farm nutrients drain into the Mississippi River, which empties into the Gulf, spurring algae to overpopulate and suffocating other aquatic life. Illinois is a main culprit in this ongoing environmental blight.

-

As Clouds Head For The Poles, Time To Prepare For Food And Water Shocks

A changing climate means less rain and lower water supplies in regions where many people live and much of the planet’s food is produced: the mid-latitudes of the Northern and Southern hemispheres, including the U.S. Southwest, southern Europe, and parts of the Middle East, southern Africa, Australia, and Chile.

-

Reducing Wastewater Hauling Through An Advanced Membrane Treatment Technology Hauling wastewater is one of the most expensive and least sustainable means of managing wastewater, significantly impacting the environment through carbon emissions, and drastically increasing operational costs. As industries strive to meet environmental and economic goals, finding sustainable wastewater treatment methods is needed — now more than ever.

-

ArxZyme™ Acetone Removal For AMPAC Fine Chemicals

AMPAC faced a critical challenge with acetone management. The high acetone levels in the effluent from its chemical processing operations required an effective industrial wastewater treatment solution to meet environmental regulations and ensure safe discharge.

-

Securing Water for Food: Investing in High-Potential Innovations

Securing Water for Food aims to source and accelerate game-changing solutions that will increase water availability and promote efficient use of water in agriculture.

-

The Key To Accurate Waste Gas Flow Measurement

Wastewater treatment facilities have a tremendous opportunity to utilize the biogas they generate to lower energy costs and minimize odors. However, the practice isn’t as widespread as it could be, as the precision gas flow and methane content readings required to optimize the process often clash with the misconception that biogas is messy and difficult to measure reliably. With the proper equipment, it is possible to accurately measure biogas to cut emissions and reduce or eliminate the energy bill.

-

Rounding Up Glyphosate's Threat To Drinking Water

A popular weed killer appears to be threatening consumer health through drinking water supplies. As knowledge around this threat grows, treatment operations should consider their technology options.