| Products from KROHNE — Always a good solution | ||||

|---|---|---|---|---|

|

KROHNE Inc. is currently headquartered in Beverly, MA and serves its North American markets through a network of representative, distributors and direct sales personnel. Our mission is to provide unparalleled application expertise, on-time delivery, and cost effective quality products so that we can exceed our valued customers' expectations. We offer a technically proficient, KROHNE-trained sales force that gets involved in all aspects of technical sales, and applications support. Our dedicated technical support, field application and repair teams are located throughout the regions to provide timely and effective services at your site or at our factory. Our TASC (Technical Application Support Center) is the heart of KROHNE's technical support capability. This group of trained engineers and technicians at your disposal by phone, fax, or e-mail for product application, installation, operation or troubleshooting questions. Our factory also stocks the most popular devices and spare parts and can also combine prefabricated device sub-assemblies into complete calibrated instruments for quick delivery. Our factory also houses calibration equipment for variable area flow meters, Coriolis mass meters, Mag meters as well as radar and TDR level instruments. We value our customers dearly and commit ourselves to putting them first. |

||||

|

|

|||

| The Important Role Of Ultrasonic Flowmeters In Biogas Production | Electromagnetic Flowmeter Survives Floods | |||

CONTACT INFORMATION

KROHNE, Inc.

55 Cherry Hill Drive

Beverly, MA 01915

UNITED STATES

Phone: 800-356-9464

Fax: 978-535-1720

Contact: Joe Incontri

FEATURED ARTICLES

-

Radar Level measurement has come a long way. Learn how KROHNE’s Optiwave 1500 series radar has moved continuous radar level measurement into the 21st century!

-

Electromagnetic flow meters offer accurate, low-maintenance flow measurement for conductive liquids—delivering long service life, low power usage, and seamless system integration without moving parts or flow obstructions.

-

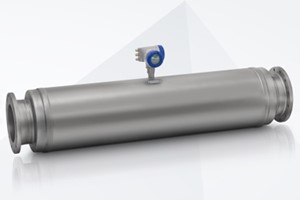

State-of-the-art measuring devices such as OPTIMASS Coriolis mass flow meters combine robust measuring principles and powerful electronics to produce a wide range of readings and device-specific data. OPTICHECK technology built-in leverages the features of the devices to translate their available comprehensive measuring system data into sophisticated diagnostics information for plant personnel.

-

KROHNE’s PipePatrol uses advanced pressure wave analysis to detect and locate leaks in real time, helping water utilities reduce non-revenue water and improve network efficiency.

-

A dedicated, manufacturer-approved verification system is the ideal solution for maintaining optimal performance of your installed base of KROHNE electromagnetic and mass flow meters.

-

KROHNE’s OPTISONIC ultrasonic meters deliver accurate, low-maintenance flow measurement for tough wastewater streams like raw sewage, sludge, and slurries—reducing maintenance, energy waste, and compliance risk.

-

Radar-based measurement like the OPTIWAVE 1520 delivers accurate, low-maintenance flow data in open channels—helping utilities reduce operating expenses, improve compliance, and overcome limitations of traditional methods.

-

Accurate measurement and control technologies are essential for achieving sustainability in water and wastewater operations by reducing energy use, minimizing losses, and optimizing chemical dosing.

-

This presentation will explore some areas in Water and Wastewater Treatment where Coriolis Mass flow meters will benefit your process and save costs when compared to traditional measurement technology and methods.

-

Choosing between free-space radar and guided wave radar systems designed for chemical service requires an understanding of their operating principles, advantages, and limitations.

-

Understanding how entrained gas can disrupt flow measurement ― and the technologies that can help overcome this challenge ― are key to ensuring reliable and efficient plant operation.

-

In this session, discover how KROHNE’s OPTIWAVE 1500 series level radar devices can be used for open channel flow applications or for chemical bulk storage tank level.

NEWS

- KROHNE Showcases Advanced Magmeter Diagnostics And Field Verification Tools For Enhanced Process Operations

- KROHNE Introduces OPTIWAVE 1530 & 1560 Radar Level Transmitters

- KROHNE To Showcase Wide Range Of Water And Wastewater Products At WEFTEC 2025

- KROHNE Dedicates Production Capacity And Establishes U.S. Center Of Excellence To Support Explosive Growth In AI-Driven Data Centers

- KROHNE Showcases Safety Innovations In Variable Area Flowmeter Technology For Critical Industrial Applications

- KROHNE To Feature Range Of Innovative Level And Process Measurement Technologies At Powder & Bulk Solids Expo 2025

- KROHNE Highlights FLEXMAG 4050C Electromagnetic Flow Meter At INTERPHEX 2025

- KROHNE Highlights Advanced Coriolis Flowmeter Technology For Precision Process Measurement

- KROHNE Launches New OPTIWAVE 1500 Product Line

- KROHNE Highlights ENVIROMAG Flow Measurement For Water And Wastewater Applications

- KROHNE Highlights Dynamic Electromagnetic Flowmeters

- KROHNE Highlights Dynamic Electromagnetic Flowmeters

- KROHNE To Highlight Benefits Of Its Flow And Level Measuring Instruments At The Irrigation Show

- KROHNE To Showcase TIDALFLUX 2300 F At Florida Water Resources Conference 2023

- KROHNE Announces OPTISWITCH 6700

- KROHNE Offers Full Instrumentation Portfolio For Produced Water

- KROHNE Adds New Courses To KROHNE Academy Online eLearning Training Platform

- KROHNE Offers Surface Passivation In Variable Area Flowmeters

- KROHNE Offers OPTIFLUX 4100 Electromagnetic Flowmeter

ABOUT KROHNE, INC.

KROHNE Inc. headquartered in Peabody, MA covers the United States, Canada, Mexico, and the Caribbean regions through a vast network of direct sales personnel and representative partners. We are on the mission of exceeding our customers' expectations by providing unparalleled application expertise, on-time delivery, and cost effective quality products. To accomplish that, we pay special attention to the following areas:

Technical Support Services...

Dedicated technical, field application and repair teams located throughout the regions provide unsurpassed customer service. Our TASC (Technical Application Support Center) is the heart of KROHNE's technical support capability with a staff of trained engineers and technicians at your disposal by phone, fax, or e-mail for product application, installation, operation or troubleshooting questions.

Local Assembly with just-in-time inventory systems...

Single and parallel bent-tube meters are completely fabricated at our Peabody facility and are exported not only to NAFTA countries but to the entire world. In addition, we hold stock on most popular items, and assemble prefabricated items to complete meters for over 70% of deliveries to NAFTA. We have our own on-site calibration facilities for variable area flowmeters, coriolis meters, magmeters and level gauges instruments.

Choose a Partner...

Don't just buy an instrument. Choose KROHNE as partner.

- Direct "Field Expert" Sales Force...

We offer a technically proficient, KROHNE-trained direct sales force that gets involved in all aspects of technical sales, product service and applications support. We are committed to providing you with KROHNE's 83 years of flow and level measurement expertise at your facility.