| THE GOLDEN RULE AT WORK SINCE 1905. | ||||

|---|---|---|---|---|

|

For more than a century, AMERICAN has been committed to doing things the right way – exceeding customer expectations, caring for our employees and building strong communities. Taking pride in our work means taking the time to do it right. And that commitment to excellence is reflected in each of the products we proudly produce. |

||||

|

|

|||

| AMERICAN Plays A Role In Rebuilding Puerto Rico's Infrastructure

|

AMERICAN SpiralWeld Pipe Delivers For City Of Phoenix Drought Pipeline Project

|

An AMERICAN Trifecta In Hillsborough County, Florida | ||

CONTACT INFORMATION

AMERICAN - American Cast Iron Pipe Company

P.O. Box 2727

Birmingham, AL 35202

UNITED STATES

AMERICAN CASE STUDIES

-

Beneath the waters of Chequamegon Bay on Lake Superior in Ashland, Wisconsin, about 4,500 feet of 24-inch AMERICAN Flex-Ring Ductile Iron Pipe and a submerged timber crib intake structure were installed to ensure the city’s residents have quality drinking water for the next 100 years. The Ashland Water Intake Project began May 1, 2025, and is now complete.

-

What began as a lofty idea will soon become a reality as a new regional water authority is established in Northwest Missouri. The Great Northwest Wholesale Water Commission will supply water to more than 11,000 people in rural areas of Cameron and Maysville, Missouri, with the capability to expand to other communities in the future.

-

Hillsborough County’s $100 million South County Potable Water Project, supported by AMERICAN, boosts water reliability and pressure through 10.7 miles of mains, using innovative Design Build collaboration.

-

Phoenix’s Drought Pipeline Project, supported by AMERICAN SpiralWeld Pipe, secures clean water for North Phoenix, delivering up to 75 million gallons daily and earning top industry awards.

-

AMERICAN is helping rebuild Puerto Rico’s vital water infrastructure after Hurricane Maria, supplying American-made products to strengthen resiliency for 3.5 million residents and millions of annual visitors.

-

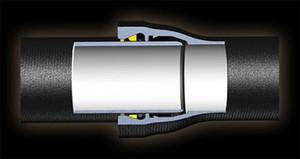

How does a contractor navigate the installation of new water and sewer mains in a neighborhood with heavy traffic, narrow roadways and extensive existing underground infrastructure? The answer is the ALPHA™ restrained joint by AMERICAN Flow Control.

-

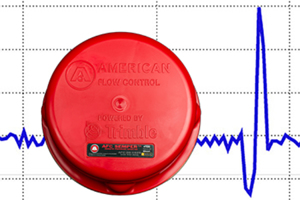

Discover how the implementation of pressure sensing technology has allowed the city of Monroe, North Carolina to gain greater insight into its distribution system and why main breaks were occurring.

-

What do the Indy Music City Grand Prix, Taylor Swift Eras Tours concerts, Country Music Awards Festival, and college and NFL football games have in common? These and other events were held at Nissan Stadium in Nashville, Tennessee, in the spring, summer and fall of 2023.

-

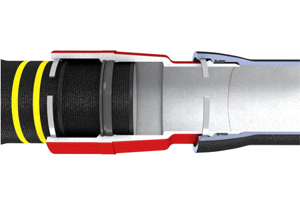

When the Grand Strand Water and Sewer Authority engaged Ruby-Collins, Inc. to expand and upgrade its water and sewer system, Ruby-Collins President and CEO Scott Cline knew the job would be challenging – beginning with the project’s scale. A key feature in the upgrade was the installation of a 48-inch spiral-welded steel pipe water main that was coated in polyurethane and five miles long.

-

In this case study, read about a community-owned utility that partnered with AMERICAN to provide 53,000 feet of ductile iron pipe for a new water reclamation facility.

AMERICAN ARTICLES

-

The primary reason the Iron Bowl is so appropriately named is that it’s a tough game, played by tough men, fighting with toughness and resilience for their teams and universities, and their fans care perhaps even more. Tough, hard-hitting, durable, resilient. All describe both the players in the Iron Bowl and the performance of ductile iron pipe.

-

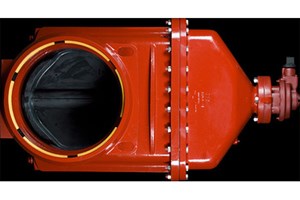

Outdated specifications can sometimes lead to confusion regarding which gate valve should be used. Understanding how the standards have evolved and why can help utilities understand the source of this confusion.

-

Up until recently, there was no empirical data to support the position that bypasses, for the routine operation of resilient wedge gate valves, are not needed.

-

Over the past year, the Water Division of the city of Miami Beach, Florida, has seen its use of AMERICAN Flow Control SEMPER Remote Pressure Monitors (RPM) grow.

-

First, it was Lake Mead, behind Hoover Dam. Now it's Lake Powell, upstream of Mead and behind Glen Canyon Dam. The water supplies supported by these feats of engineering are dwindling. There are many reasons, but it's not necessary.

AMERICAN IN THE NEWS

- AMERICAN Cast Iron Pipe Company Acquires C&B Piping

- AFC SEMPER RPM Helps Portland, Tennessee, Gain System Knowledge And Improve Non-Revenue Water

- Helping Our Neighbors in Asheville Get Back on Their Feet After Hurricane Helene

- AMERICAN Makes The Cut To Share In $6 Billion In Federal Funding For Decarbonization Projects

- Specification Rubber Expands Its Operations In Shelby County

- The Iron Bowl And Your Water Pipe – Neither Ever Disappoints

- Which Gate Valve Is Best For Today's Waterworks Systems?

- Are Bypasses Needed With Today's Waterworks Gate Valves? New Information Says They're Not.

- AFC SEMPER® Remote Pressure Monitors Provide Real-Time Insight To Miami Beach Water

- Lakes Powell And Mead Don't Have To Dry Up

ABOUT AMERICAN CAST IRON PIPE COMPANY

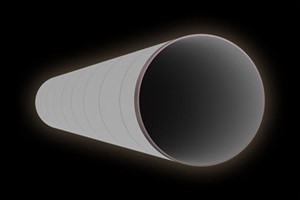

American Cast Iron Pipe Company, founded in Birmingham, Ala., in 1905, is a manufacturer of ductile iron pipe, spiral-welded steel pipe, fire hydrants and valves for the waterworks industry, and electric-resistance-welded steel pipe for the oil and gas industry. AMERICAN’s diversified product line also includes static castings and high-performance fire pumps.

The Birmingham plant, located on a 2,000-acre site with more than 60 acres under roof, is home to one of the world’s largest cupolas; the Contiarc, the first-of-its-kind continuous arc furnace; and AMERICAN Recycling, the only scrap processing facility of its kind in the region.

AMERICAN employs approximately 3,000 people – about 2,000 at its headquarters plant and offices in Birmingham, and about 1,000 at its subsidiary plants: American Castings, LLC, Pryor Creek, Okla.; American SpiralWeld Pipe Company, LLC, Columbia, S.C.; American Valve & Hydrant Manufacturing Company, Beaumont, Texas; Intercast SA, Itauna, Brazil; Specification Rubber Products Inc., Alabaster, Ala.; Pneumax of Peoria, Ariz.; and Waterous Company, South Saint Paul, Minn.

Ductile Iron Pipe: 800-442-2347

Valves and Hydrants: 800-326-8051