| Monsters Work Here! | ||||

|---|---|---|---|---|

|

JWC Environmental's family of wastewater, stormwater and sewage treatment products are legendary for quality and reliability – including the Muffin Monster® and Channel Monster® sewage grinders, and the Auger Monster®, Screenings Washer Monster® and Monster Separation Systems®, which incorporate a fine screen or band screen with superior sewage screening conditioning. |

||||

|

|

|||

| Brochure: Muffin Monster Manhole | Channel Monster Cuts Maintenance Costs And Protects Pumps In Santa Ana | |||

CONTACT INFORMATION

JWC Environmental

2850 Red Hill Ave., Suite 125

Santa Ana, CA 92705

UNITED STATES

Fax: (714) 242-0240

Contact: jwce@jwce.com

FEATURED CASE STUDIES AND ARTICLES

-

Successful headworks investments depend on understanding site needs, matching technology to application, evaluating total cost of ownership, and choosing vendors that prioritize long-term performance and reliable support.

-

From ragging and grit to odors and cost constraints, wastewater operators face persistent challenges. Proven headworks technologies and preventative maintenance help utilities improve performance, reduce downtime, and control costs.

-

While grinders have a reputation for being an install-and-forget technology, they can still be optimized and maintained for peak performance.

-

Learn about a solution that employs a combination of grinding, solids removal, washing, and dewatering, and enables a typical septage truck to unload in 5 to 15 minutes.

-

Some industry professionals have concluded eliminating the use of grinders will prevent microplastics from entering the water cycle. This thinking is wrong for a range of reasons.

-

When the Kearney, MO wastewater treatment plant began plans to upgrade its headworks they choose JWC Environmental’s Brushless Finescreen Monster to replace its old coarse screen.

JWC VIDEOS

-

The Honey Monster Septage Receiving Station is based on proven Auger Monster® technology, which allows cleaner handling of septage truck waste through separation of solids. The unique combination of grinding, washing and dewatering septage waste can be accomplished in approximately 5 to 15 minutes for a typical septage truck.

-

The Finescreen Monster® incorporates a continuous band of stainless steel or optional StapleGuard™ ultra high molecular weight (UHMW) polyethylene perforated panels attached to heavy-duty stainless steel roller chains. Panels are available with 1/8″ or 1/4″ (3 or 6mm) openings.

-

The patent pending Channel Monster FLEX consists of a FLEX Grinder and a Solids Diverter with perforated screen connected by a FLEX Frame. The Channel Monster FLEX continues the Channel Monster legacy of high flow capacity while capturing and shredding rags, rocks, wood, and other solids into small pieces to pass harmlessly through pumps, pipes, and process equipment.

-

In today’s modern wastewater treatment plants, meeting high standards in effluent quality, cost efficiency and odor control is a must. To meet these higher standards, JWCE introduces the Bandscreen Monster®, a member of the Monster Separation System® line of high performance screens.

-

The key to the Screenings Washer Monsters® discharge is grinding. It breaks open rags, plastics, and trash to expose more surface area for washing and removing soft organics. Liquefied organics return to the plant flow and allow the SWM to achieve dry solids content up to 50%.

JWC ENVIRONMENTAL

JWCE Waste Grinder Demo

Food Waste Grinding Video

|

The patented Muffin Monster® design has established new standards in product performance and reliability due to decades of technical advancements and innovative design improvements. Adapts to pipelines or channels with little or no modification and custom stainless steel frames allow easy installation in channels, wet wells and pump stations. |

|

Channel Monsters® easily replace troublesome bar screens and comminutors — helping you reduce operating and maintenance costs. Clean, powerful, reliable and cost effective – Channel Monster is the industry’s high-flow grinder of choice! |

|

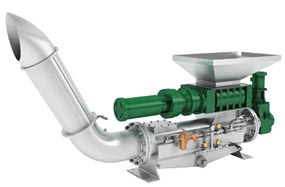

The Auger Monster® is a robust and affordable wastewater screen which combines three of JWC’s finest technologies – a grinder, a fine screen and a compactor. It removes trash and unwanted solids. The new Vertical Auger Monster protects pump stations from non-dispersible wipes. |

|

Monster Separation Systems® are a complete, high-performance system that provides high capture rate of wastewater solids and more efficient washing and compacting, resulting in a discharge that is remarkably clean and ready for disposal. The more unwanted solids removed at the headworks of your treatment plant, the better the whole facility will run. |

|

The Screenings Washer Monster® (SWM) produces ultra-clean discharge using a patented system to grind, wash, compact and dewater debris captured by a screen. This self-contained, hopper fed system produces the industry’s cleanest most compact screenings discharge. |

|

The Honey Monster® Septage Receiving Station is based on proven Auger Monster® technology, which allows cleaner handling of septage truck waste through separation of solids. The unique combination of grinding, washing and dewatering septage waste can be accomplished in approximately 5 to 15 minutes for a typical septage truck. |

|

3‐SHRED

4 cutter stack sizes: 8” (200mm), 12” (300mm), 18” (450mm), and 24” (600mm) Motor size: 5HP (3.7 kW)Applications: MARPOL, Food Waste, Agriculture, Petroleum |

|

4‐SHRED 3 cutter stack sizes: 18” (450mm), 24” (600mm) and 32” (800mm) Motor size: 10HP (7 kW) Applications: Agriculture, Food Waste, Product Destruction, Depackaging, Recycling *model shown with optional hopper |

|

7‐SHRED 3 cutter stack sizes: 30” (762 mm), 40” (1016mm) and 50” (1270mm) Motor size: 25 - 50HP (18.5 - 37 kW) Applications: Agriculture, Food Waste, Product Destruction, Recycling |

|

The Monster Industrial Fish Cleaning Station is the most efficient fish cleaning station available. The self-contained unit uses a powerful HYDRO dual-shafted grinder to shred solids, such as fish parts, cans, plates, utensils and fishing lures. |

|

The Zero Waste Monster ™ (ZWM) is a self-contained, hopper-fed system designed to separate liquids, gels, creams and semi-solids from their plastic, glass or metal containers. This patented system will give you the peace of mind of onsite product destruction, while saving you money in waste hauling and landfill fees. Applications: Depackaging, Recycling |