ABOUT CALGON CARBON CORPORATION

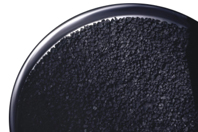

Calgon Carbon, a wholly-owned subsidiary of Kuraray Co., Ltd. (TYO: 3405) (Kuraray), is a global leader in the manufacture and/or distribution of innovative coal-, wood- and coconut-based activated carbon products – in granular, powdered, pelletized and cloth form – to meet the most challenging purification demands of customers throughout the world. Calgon Carbon provides purification solutions for more than 700 distinct applications, including drinking water, wastewater, pollution abatement, and a variety of industrial and commercial manufacturing processes. Headquartered in Pittsburgh, Pennsylvania, Calgon Carbon employs approximately 1440 people and operates 20 manufacturing, reactivation, innovation and equipment fabrication facilities in the U.S., Asia, and in Europe, where Calgon Carbon is known as Chemviron. Calgon Carbon was acquired by Kuraray in March of 2018. With complementary products and services, the combined organization will continue to focus on providing the highest quality and most innovative activated carbon and filtration media products, equipment, and services to meet customer needs anywhere in the world. Visit CalgonCarbon.com.

FEATURED ARTICLES

-

While performance and cost matter, there are a range of other factors that can have a substantial impact on the overall viability and success of a solution.

-

Analyzing a GAC sample reveals if the media should be reactivated or disposed of. Therefore, it is critical that operators follow this definitive guide for pulling a representative sample.

-

A poor underdrain design can cause filtration inefficiencies and inconsistencies, including uneven pressure drops and dead zones where water flows slowly or not at all.

-

Bed conditioning and startup procedures are designed to optimize the performance of the carbon bed and maximize adsorption capacity to achieve treatment goals.

-

Follow these key steps to conduct a successful pilot study to help remain below their target contaminant limits and cost-effectively comply with regulations.

-

A first-hand account of how Calgon Carbon Corp. executed a last-minute clean jet fuel contaminated water around the Joint Base Pearl Harbor-Hickman.

-

This introduction to volatile organic compounds (VOCs) will discuss what qualifies a compound as a VOC, how to detect them, and how to treat and remove these chemicals from the water system.

-

Water treatment plants (WTPs) need to lean less on the disinfection process strategies (i.e., chloramination) and instead focus on more comprehensive DBP solutions such as removing TOC. Here's why.

-

Whether a water treatment plant (WTP) is evaluating a new granular activated carbon (GAC) solution to deal with contamination problems such as PFAS, DBPs, and VOCs or looking to enhance existing GAC performance, it is important to assess treatment processes in the full context of source water quality. Here are some ideas to help decision-makers achieve the best outcomes at the lowest total lifecycle cost.

-

Here are some considerations that can help water treatment plant (WTP) supervisors, operators, and their consulting engineers achieve their PFAS removal goals more efficiently and cost effectively despite the added challenges.

-

Choosing the right media is only the first step. Vessel and underdrain design often determine whether filtration systems meet expectations — or quietly fall short over time.

-

Dr. Rosa Yu, National PFAS Lead at Carollo Engineers, discusses the fate of PFAS as treatment technologies evolve from removal with a PFAS byproduct to complete destruction, which would eliminate the chemicals from the water cycle, thus taking "forever" out of their name.

-

Adam Feffer, National PFAS Practice Leader at Black & Veatch, lists the Best Available Technologies, or BATs, that the U.S. EPA has recognized for the removal of per- and polyfluoroalkyl substances (PFAS). According to the current rule (but subject to change), solutions to remove two specific PFAS — PFOA and PFOS — down to 4.0 parts per trillion must be implemented by 2029. Drinking water utilities will likely select among the treatment options shared in this clip.

-

Filtrasorb 400’s agglomerated pore structure and high volumetric capacity deliver unmatched PFAS removal, longer run times, and lower lifecycle costs—outperforming direct-activated carbons in real-world and lab testing.

-

The Cape Fear Public Utility Authority (CFPUA) provides drinking water to more than 200,000 residents in the Wilmington, North Carolina area. In 2017, the community learned that per- and polyfluoroalkyl substances, or PFAS as they are more commonly referred, were contaminating CFPUA’s drinking water source. This led CFPUA to partner with Calgon Carbon to install Filtrasorb® granular activated carbon (GAC) to remove PFAS from the water at their Sweeney Water Treatment Plant. With this GAC addition, PFAS concentrations were reduced to levels at or near non-detection.

-

Thermal reactivation of granular activated carbon is a proven and scalable method to achieve >99.9% destruction removal efficiency for PFAS. This process fully restores the carbon for reuse, providing a sustainable solution that breaks the cycle of "forever chemicals."

-

Calgon Carbon’s Dr. Angela Rodriguez shares insights on PFAS treatment, regulatory readiness, sustainability, and how innovative carbon technologies help utilities balance compliance, cost control, and environmental goals.

-

This article will explore five common misconceptions about GAC and IX technologies for PFAS removal, helping utilities choose effective, site-specific treatment strategies for contaminated drinking water.

-

Calgon Carbon, the global leader in activated carbon water treatment solutions, will be exhibiting at booth #1944 at the American Water Works Association's 2025 Annual Conference & Expo (AWWA’s ACE25) taking place June 8-11, 2025, at the Colorado Convention Center in Denver, Colorado.

-

Learn why the U.S. EPA has recognized granular activated carbon (GAC) as a best available technology (BAT) for a wide range of substances within the same system.

-

Calgon Carbon Corporation (Calgon Carbon), a wholly owned subsidiary of Kuraray Co., Ltd. (TYO: 3405) (Kuraray) and American Water (NYSE: AWK), the largest regulated water and wastewater utility company in the U.S., jointly announce the signing of a nine-year exclusive supply contract providing granular activated carbon, equipment and reactivation services to more than 50 American Water sites across 10 states.

-

Calgon Carbon’s AquaKnight GC systems are designed from the top down to improve flow, adsorption, and media life.

-

While any company can claim to offer these services, WTPs need a total solutions provider that understands GAC technology as only a manufacturer can.

-

This article aims to help utilities and municipalities to better understand the startup process and offer solutions to reduce the amount of water needed to get GAC filters online.

-

This guide can help operators ensure seamless granular activated carbon (GAC) media changeouts, minimizing downtime and maintaining high water quality standards.

-

With decades of experience in hazardous waste reactivation, Calgon Carbon is well-prepared to adapt to any regulatory changes when addressing PFAS. Tune in to hear Dr. Angela Rodriguez, applications engineer for Calgon Carbon, highlight the effectiveness of GAC to tackle PFAS contamination.

-

In a world where access to clean and safe water is increasingly vital, AquaKnight emerges as the steadfast guardian of clean drinking water in the ongoing battle against PFAS.

-

Calgon Carbon has been implementing high-performing adsorption equipment for over 35 years and has developed expertise in design, manufacture, and utilization of activated carbon solutions. These solutions offer customers the lowest total cost of ownership along with superior performance, ease of carbon changeouts, and the ability to treat to very low levels.

-

NSF-certified systems have the same benefit as individually certified components but can often be produced more cost effectively.

-

This article will discuss two of the most common drinking water sources and how they affect treatment priorities and configurations.

-

In this episode of Water Talk, Angela Godwin sits down with Adam Redding from Calgon Carbon Corporation to talk about PFAS and more.

-

Read about a stack testing program at a full-scale GAC reactivation facility during the reactivation of a load of GAC known to contain adsorbed PFAS.

-

The U.S. EPA recently announced its proposal for what would be the first-ever national drinking water standards for PFAS. This news likely triggered several questions about what this means to the drinking water industry. Here, we will address some of the most important ones.

-

Learn how naturally occurring biological growth on carbon media can help enhance removal of total organic carbon (TOC) and thusly reduce the formation of DBPs.

-

In this segment from Virtual Water Expo, Dr. Adam Redding discusses a dual media (IX/GAC) approach for PFAS removal.

-

Water treatment plants (WTPs) that deciding between ion exchange (IX) or granular activated carbon (GAC) systems should weigh the operation and maintenance of each before implementing either technology.

CONTACT INFORMATION

Calgon Carbon Corporation

3000 GSK Drive

Moon Township, PA 15108

UNITED STATES

Phone: 800.422.7266

Contact: Info@CalgonCarbon.com