SEPARATION & CLARIFICATION RESOURCES

-

From modifying existing equipment to tailoring batch and fully automated systems, working with an experienced provider can help to assure integration and compliance with surprisingly fast ROI.

-

The appropriate selection of polymer and a make-down system improves the water clarification process and significantly reduces costs.

-

Top biopolymers for wastewater treatment represent a big step toward better water quality. They offer a more sustainable approach compared to conventional synthetic and inorganic clarification solutions. However, before getting into specific details, it’s crucial to grasp the role of these materials in addressing various wastewater related issues.

-

Reducing biochemical oxygen demand (BOD) in wastewater is a key challenge for treatment facilities, but some solutions can help. BOD is a crucial factor in monitoring water quality and safety, and achieving a low BOD is one of the top goals of any plant.

-

We all love it when a plan comes together. In July 1952 in Arkansas, when President Harry S. Truman dedicated the Bull Shoals dam on the White River, which created Bull Shoals Lake, it, as planned, brought about a boom in tourism — and how.

-

The Littleton / Englewood Wastewater Treatment Plant, just south of Denver, is the third largest publicly owned treatment works in the state of Colorado. It receives sewage from the cities of Littleton and Englewood, as well as 21 connector districts in a 75-square-mile service area. Farmer’s staff chose to implement an upgraded grit removal system supplied by Hydro International. Two complete HeadCell® systems were implemented – each consisting of one HeadCell® grit separation unit, one SlurryCup™ grit washing unit, and one Grit Snail® grit dewatering escalator. Read the full case study to learn more.

-

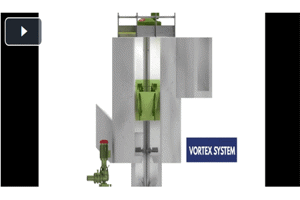

The existing aerated grit basin (AGB) grit removal system at Fox Lake, IL, was at the end of its useful life and needed to be replaced. There were two requirements for the replacement: they wanted to retrofit the new equipment in the existing area and to eliminate grit deposition in the grit basin which was very difficult to remove. Steve Vella, Fox Lake’s plant Supervisor, saw the HeadCell® at WEFTEC in Chicago. He liked the stacked tray concept, and thought it would be the ideal solution to their plant’s grit problem. He had seen similar operational principles in lamella systems. The stacked tray design would allow them to increase their surface area which would increase their grit system performance, while staying within the existing area used by the AGB.

-

The original plant in Green Lakes, WI, was built in 1983 and did not include grit removal. As a result, grit accumulated throughout the plant process tanks, particularly the aeration basin. This required periodic shutdown of the process tanks and hiring a contractor to vacuum the deposited grit from the tanks. The pending upgrade would include the use of an SBR treatment system as well as an upgrade to sludge dewatering. Plant personnel were concerned about grit settling in the process tanks, as well as grit wearing on the belts and rollers of the new belt filter press that would be used for sludge dewatering. The impact of these problems drove the plant to include grit removal in their upgrade project.

-

We cook with it. Use it on our skin. Paint with it. Use it to fuel our cars. Our own bodies even produce it. However, something doesn’t quite add up here. Clearly, you wouldn’t cook with motor oil and you wouldn’t put olive oil in your gas tank. So why do we call these different products by the same general name? What oily water treatment is used to treat these different types of emulsified oils?

-

Every stage in a wastewater treatment process is important to achieve the desired treatment results. However, primary treatment and tertiary are critical to the overall process. In the primary treatment process, solids are reduced to a large extent. Without this step, subsequent treatment would be less effective. In tertiary treatment, harmful microbiological matter is rendered killed or inactive so that it will not cause sickness to those organisms that encounter it.