Oily Water Treatment: How To Treat Using Advanced Electrocoagulation

By Nick Nicholas

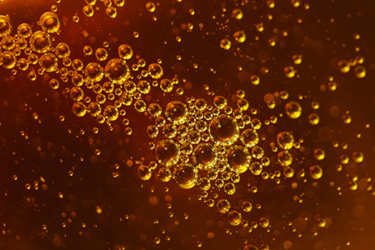

We cook with it. Use it on our skin. Paint with it. Use it to fuel our cars. Our own bodies even produce it. However, something doesn’t quite add up here. Clearly, you wouldn’t cook with motor oil and you wouldn’t put olive oil in your gas tank. So why do we call these different products by the same general name? What oily water treatment is used to treat these different types of emulsified oils?

We called these oils by the same general name due to their physical similarities than chemical compositions. Oils are classified as such because of their texture, hydrophobic tendencies, and nonpolar ionic nature. They are also typically flammable. Nonpolarity makes oils excellent lubricants as they won’t stick to other materials. Some animals, like ducks, make use of hydrophobic oils to keep their hair or feathers dry in water. Cooking oils can even double as fuel for automobiles in place of refined crude oils.

All oils are organic in origin but have different chemical compounds and structures. Crude oils are the byproducts of organisms exposed to high temperatures and pressures over millions of years. These are mainly comprised of hydrocarbon compounds. Oils produced by plants, animals, and other organisms are formed by natural metabolic processes and are made up of lipids.

However, as useful as oil is in our everyday lives and within industry, it is not something that is desired in wastewater. So, how does it end up in wastewater? Why is it harmful? What are the oily water treatment methods?

Industries That Produce Oily Wastewater

Due to the wide variance of what counts as oil, there is a broad range of industries that produce wastewater that fit under the umbrella of “oily”. There are the more obvious sources like companies that make cooking oils, mining companies, refineries, and restaurants to name a few. Other potential sources of oily wastewater include:

-

Ship bilge and ballast water

-

Aircraft and vehicle maintenance stations

-

Leaking oil tanks

-

Stormwater runoff

-

Machine shops

-

Meat/poultry processing

-

Fish processing

-

Dairy processing

-

Paint production

-

Soap and detergent production

-

Textiles

Issues From Oily Wastewater

Like many wastewater contaminants, oils are harmful to the surrounding environment in excessive quantities. These compounds cause problems with aquatic and plant life, including killing fish, leaving birds and mammals susceptible to hypothermia or overheating, and damage and stunted plant growth, which also negatively impacts wildlife. Oils can also cause adverse health effects to humans and can cause clogging in pipes.

How Electrocoagulation Can Treat It

Oily wastewater comes in a few different forms and require different oil and grease removal methods. Floating oils are seen when oil and water have fully separated out. This occurs naturally and fairly quickly thanks to both oil’s proclivity to coalesce and its specific gravity being less than water. However, oil can be emulsified within water as well. When broken into small droplets, oil can remain suspended within the solution for a time period. Emulsions can occur by mechanical means, like whisking a pot of oil and water, but these are unstable emulsions that will separate out quickly, leaving only the smallest droplets suspended. Chemical emulsions on the other hand typically introduce an emulsifier that stabilizes the suspension by reducing the forces between the droplets and the water. Separation can still occur, however, it will occur much more slowly.

The main issue with treating oily wastewater is breaking emulsions. An effective method to break these emulsions in oily water treatment is via specialized electrocoagulation. Using this process to destabilize the solution, will allow the oil droplets to coagulate and float to the surface. In some cases, oil may even adhere to solid particles and settle in a post clarification process. In many other treatment methods, some sort of destabilizing agent must be added into the solution as with flotation methods and coagulation.

However, this de-emulsifying by destabilization can be done without any chemical additives.

Enter, electrocoagulation.

Electrocoagulation (EC) works by supplying a current to an array of metal electrodes. The anodes go through oxidation whereby metal ions are released into the electrolyte. These ions neutralize the charge of the solution and destabilize it as a result. So, in the case of oily wastewater, the metal ions would serve to destabilize the oil/water emulsion, allowing the oil droplets to coalesce and rise to the surface. The separation is also helped along by the cathode. While the anode is oxidizing, the cathode produces bubbles that aid in the flotation of these particles.

Several studies have been performed to analyze the effectiveness of EC as an oily water treatment method. This paper summarizes many different applications of electrocoagulation in water treatment. Section 3.3 outlines oily water treatment from several of the sources mentioned above.

Oily wastewater treatment can be difficult and costly to treat with other methods. Flotation and chemical coagulation require large amounts of chemical additives to enable oil removal, and methods like ion exchange and filtration will just end up being fouled by the oil in the wastewater stream.

Electrocoagulation, on the other hand, does not have these shortcomings. The reactor tanks are easy to operate, use and maintain, and there are no chemicals required for destabilization. As a bonus, it also produces dramatically lower volumes of sludge that can often be used in land applications, if applicable.