ABOUT BLUE-WHITE INDUSTRIES

Blue-White Industries was built on a cornerstone of core values that still stands today: Quality, Service, Performance and Innovation.

Blue-White® is a manufacturing company located in Huntington Beach, California, and was founded by Ozzie King. Ozzie had previously owned and operated a successful construction business in Los Angeles. While running that enterprise he became aware of a need for important products which were not readily available. He decided to begin manufacturing these products himself and Blue-White Industries was born.

Blue-White was incorporated in 1957 and is still owned and operated by Ozzie King’s heirs including his grandson, company President and CEO Rob Gledhill.

What began as a small company with just four permanent employees now boasts a workforce of over 100 individuals, as well as a worldwide network of Representatives and Service Centers.

The company offers a full-spectrum of product lines including; Chemical Feed / Dosing pumps, both diaphragm and peristaltic styles; Complete Skid Systems; Variable Area, Digital and Ultrasonic Flowmeters; and a variety of ancillary products.

All Blue-White products are designed to be simple to order, easy to install, environmentally friendly and to require very little, if any, maintenance.

A team of topnotch engineers coupled with the latest equipment and manufacturing processes, and fueled by our mission to design and build the highest quality, most innovative products on the market, has made Blue-White a leader in several industries.

Markets served include; Municipal Drinking Water and Wastewater Treatment; Industrial Process Water and Wastewater Treatment; Agricultural and Poultry Industries including fertilizer and nutrient injection, Food and Beverage Process Water Purification, Color and Flavor Injection and Wastewater Treatment, Brewing, Aquatics and many others.

All Blue-White Industries Products are Manufactured in the USA. Blue-White® is ISO 9001:2015 Certified.

CONTACT INFORMATION

Blue-White Industries

5300 Business Drive

Huntington Beach, CA 92649

UNITED STATES

Phone: 714-893-8529

Contact: Danny Sanders

VIDEOS

-

Take a quick tour of the Blue-White factory in Huntington Beach, California, where skilled employees are busy building chemical dosing pumps, complete metering systems and flow measurement equipment.

-

In this episode of The Water Online Show, host Travis Kennedy explores the technology reshaping chemical dosing: Blue-White’s Enhanced MD1 metering pump. President Rob Gledhill breaks down how the pump’s dual-diaphragm design delivers near-continuous feed, eliminates vapor lock risks, and boosts accuracy without stroke adjustments.

-

In the latest episode of The Water Online Show: On Location, Angela Godwin sits down with Rob Gledhill from Blue-White Industries to discuss the latest innovations in chemical and fluid metering.

-

In this episode of Water Talk, we sit down with Taylor Gledhill from Blue-White Industries to discuss simplifying chemical feed through innovation.

-

In this episode of Water Talk, Blue-White's Taylor Gledhill discusses bringing simplification to life and how simplification can help to improve the world around us.

-

Listen as Taylor Gledhill from Blue-White Industries discusses the new FLEXFLO M5 peristaltic metering pump.

-

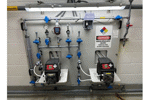

The CHEM-FEED® Triplex Engineered Skid Systems are lightweight and arrive fully assembled with all necessary components to get your system up and running quickly. The drop-in place design of the Triplex Skids help makes them easy to order and they are simple to operate.

-

The CHEM-FEED® CD1 Multi-Diaphragm Chemical Metering Pump does not lose prime when pumping chemicals that off-gas, thanks to the exclusive hyperdrive technology which allows for nearly pulse-less chemical feed. This low-maintenance pump can dose chemical against high pressures, unlike most peristaltic pumps. In addition, it communicates with Blue-White’s S6A and Micro-Flo flow verification sensors.

-

Are you using chemical metering pumps? Are you looking for a pump that is not only easy to work with, but is also simple to maintain?

-

Watch the video as Rob Gledhill from Blue-White introduces the CD3 Dual Diaphram Metering Pump, designed to precisely inject chemicals into a system and address problems with existing pump technologies.

-

Blue-White’s President Rob Gledhill takes you on a photo tour of the factory to review various obstacles they’ve had to overcome, and talk about improvements made recently. Watch the full slideshow to learn more.

-

The Proseries-M® line includes FLEXFLO® Peristaltic dosing pumps. Three models M2, M3 and M4 are offered to meet the critical demands of small, mid-size and high volume treatment plants. These units meter precise amounts of water and wastewater treatment chemicals and include a host of features and options. NSF61 listed.

-

Butte-Silver Bow Water Utility Chief Operator Jim Kennan talks about his success with the MD3 Multi-Diaphragm Metering Pump.

-

Water Treatment Supervisor Phil Sipes talks about his success with the MD3 Multi-Diaphragm Metering Pump.

-

Chris Garcia, a long-time water professional at Camp Pendleton, and Phil Sipes, Water Treatment Supervisor, talk about the features and benefits of Blue-White’s MD3 Multi-Diaphragm Metering Pump. Watch this video to learn more.

-

Nathan Kutil, lead designer for HDR Engineering, talks about how Blue-White stepped up and helped in a time of need for the city of county of Butte Silver Bow, Montana. Watch this video to learn more.