CONTACT INFORMATION

Aerzen

108 Independence Way

Coatesville, PA 19320

UNITED STATES

Phone: 484-288-6367

Contact: Ralph Wilton

FEATURED ARTICLES

-

Discover how Aerzen’s new hybrid blowers are shaping the future of energy-efficient wastewater treatment while tackling the challenges of regulatory compliance.

-

Explore some common safety devices used in aeration blowers, how they work, the potential consequences of their failure, and best practices for inspection and maintenance.

-

“Amid ‘long-term severe staffing shortages’ at the Back River Wastewater Treatment Plant, Baltimore City officials approved more private contracting help … to run the plant’s day-to-day operations,” The Baltimore Sun reported. “The city’s spending board approved a new five-year, $50 million contract requested by the Baltimore Department of Public Works for a company to handle ‘biosolids management’ at the facility.”

-

Many wastewater treatment plants are discovering flow-based blower and valve control strategies are better suited to their needs than pressure-based control strategies.

-

As a startling volume of untreated sewage spews into British source water, a major European water company has explained that it's actually better than the alternative.

ABOUT AERZEN

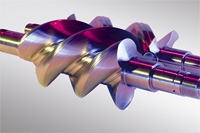

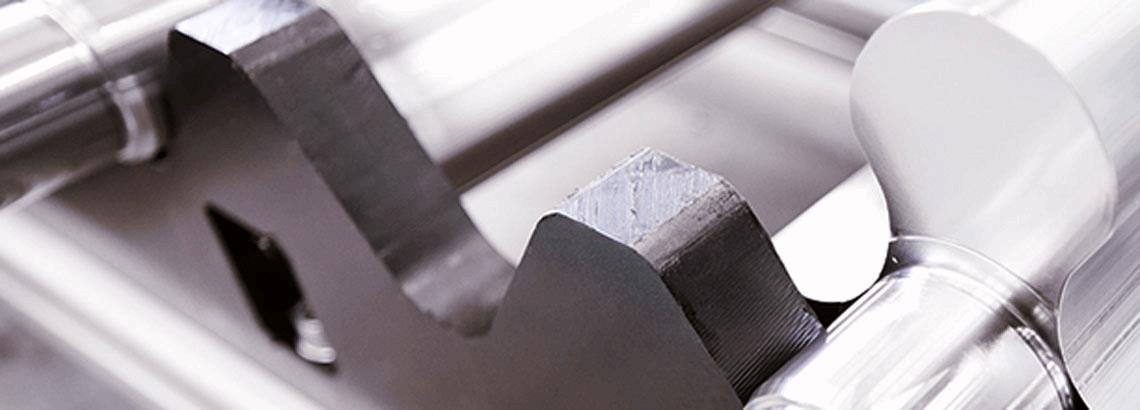

Aerzen USA was founded in the United States in 1983, and is a wholly owned division of the German manufacturer, Aerzener Maschinenfabrik GmbH. Founded in 1864, Aerzener Maschinenfabrik is a recognized world leader in the production of rotary positive displacement machines since 1868.

Continuous improvements in our production facilities, staff training, and innovations in our product offerings provide our customers with the best product and service available in the blower and compressor market today.

Our presence in North America has grown steadily since our establishment in 1983. Our customers are most pleased by the dependable operation of Aerzen blowers and compressors, low life cycle costs, and Aerzen Quality as a standard.

Aerzen USA Blog: “For in-depth insights into Water Treatment aeration see the information from the blower & compressor experts at Aerzen USA”.

Subscribe to our Company Newsletter

Click Here To Download:

•Video: Delta Blower Generation 5

Money Found In Puget Sound: Aeration Blower Saves $44K Annually For WWTP

Water Online Radio case studies are a new, convenient way to discover water/wastewater solutions that are working for customers in the field. In this first installment, you'll learn:

Water Online Radio case studies are a new, convenient way to discover water/wastewater solutions that are working for customers in the field. In this first installment, you'll learn:

- the difference between positive displacement, turbo, and hybrid blowers.

- how to find your efficiency "sweet spot"

- how Aerzen helped a utility save an estimated $44,000 per year.

VISION AND MISSION

OF THE AERZENER MASCHINENFABRIK GMBH AND THE AERZEN GROUP

As one of the world's leading suppliers of twin shaft rotary piston machines we offer our customers tailored technical solutions.

|

Company Global acting and creating solutions with competence for our clients We are a globally acting family-owned company with subsidiaries and trading partners in the most industrialized countries of the world. |

|

Quality Customers demands are our define our standard of quality Our technical equipment, our work processes and our production systems constitute the prerequisite for meeting our customers' demands in quality. To fulfill these demands keeping the leadership in technology in our fields of business has the absolute priority. |

|

Customers Focus on Customer needs Our products and services have to meet highest expectations of our customers in terms of quality and value. Therefore, all our employees are requested to work closely with our customers. |

|

Management Frank Communication, Team Spirit and Trust Our managers encourage their employees to express freely their opinion. |

|

Employees Engagement, Individual Initiative and Diversity of Opinions Our employees are the source of our success in the global market. Together we will create a safe and pleasant working environment that respects the diversity of our staff and their individual performance. |

|

Profitability Our companies welfare and development depends on its financial strength The independence of our company depends on its financial strength. To protect this independence and the corresponding level of freedom, our company has to yield an appropriate profit. |

|

Innovation Innovation on all levels and in all roles and positions Innovation is the prerequisite to successful growth in the global competitive environment. |

|

Globally Acting Customer closeness through worldwide presence As group of companies acting in a competitive international market, we focus on meeting our customer's requirements of global support. |