WATER INDUSTRY FEATURES, INSIGHTS, AND ANALYSIS

-

PFAS Settlements: Debunking The Myths And Revealing What's Really At Stake For Water Utilities Misinformation and confusion could prevent some utilities from benefitting from the aqueous film-forming foam multidistrict litigation (AFFF MDL) settlements. Here are five common myths about the AFFF MDL PFAS settlements and how public water systems can make the most of this unprecedented funding opportunity.

-

When Chemistry Meets Water Innovation

Nobel-winning molecular materials are poised to reinvent purification, desalination, and reuse.

-

Solving The World's Microplastics Problem: 4 Solutions Cities And States Are Trying After Global Treaty Talks Collapsed

Microplastics seem to be everywhere — in the air we breathe, the water we drink, the food we eat. Countries have tried for the past few years to write a global plastics treaty that might reduce human exposure, but the latest negotiations collapsed in August 2025. While U.S. and global solutions seem far off, policies to limit harm from microplastics are gaining traction at the state and local levels.

-

AEC System Proven Effective For Chloride Removal

In two bench-scale tests, a new technology effectively removed up to 99% of chlorides and 97% of total dissolved solids in a single pass. This solution offers a commercially viable alternative to traditional treatment methods.

-

Common Misconceptions Are Keeping Lakes "Sick"

Long-held misconceptions about lake management fuel the intensity and recurrence of harmful algal blooms.

-

Colorado's Subalpine Wetlands May Be Producing A Toxic Form Of Mercury — That's A Concern For Downstream Water Supplies

The wetlands found across the Rocky Mountains of Colorado just below tree line are crucial for regulating the supply of clean water from the highlands to metropolitan regions downslope, including Denver. However, new research shows the wetlands also harbor a health risk.

-

Grand Canyon's Dragon Bravo Megafire Shows The Growing Wildfire Threat To Water Systems

As wildfire crews battled the Dragon Bravo Fire on the Grand Canyon’s North Rim in July 2025, the air turned toxic. A chlorine gas leak had erupted from the park’s water treatment facility as the building burned, forcing firefighters to pull back. The water treatment facility is part of a system that draws water from a fragile spring. The fire also damaged some of the area’s water pipes and equipment.

-

What Are Legionella Log Books And Why Are They Important? Implementing and managing a Legionella control regime can sometimes seem daunting and complex. Invariably, a lot of resources, time, and effort are needed to achieve the required standard and provide assurance to senior management and auditors that controls are effective and those that are not are being managed and rectified appropriately.

-

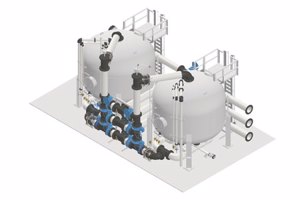

How ABB's Flow And Digital Technologies Help Bawat With Smarter Ballast Water Compliance

The International Maritime Organization (IMO) sets strict global standards for ballast water management to prevent the spread of harmful aquatic organisms. For companies like Bawat, a Danish innovator in ballast water management, being able to verify ballast water flow measurements quickly, accurately, and from anywhere in the world is essential.

-

PFAS Policy In 2025: Why It's Time To Go Beyond Remediation The most common techniques for disposing of PFAS may no longer be good enough.

VIEWS ON THE LATEST REGS

-

With the U.S. EPA's PFAS rules now in place, utilities are finding themselves with a growing number of questions regarding how to treat these chemicals, the potential costs, and much more. For answers, Water Online's chief editor, Kevin Westerling, hosted an Ask Me Anything session featuring Ken Sansone, Senior Partner at SL Environmental Law Group; Kyle Thompson, National PFAS Lead at Carollo Engineers; and Lauren Weinrich, Principal Scientist at American Water.

-

A Q&A to explain and resolve issues confronting water suppliers as they endeavor to comply with the monitoring requirements of federal PFAS regulations.

-

Assessing what lies ahead in the 10-year race to go lead-free, otherwise known as the Lead and Copper Rule Improvements (LCRI).

-

Many water systems are still tackling the challenge of identifying and compliantly managing galvanized and galvanized-requiring-replacement (GRR) service lines.

-

In the most recent edition of Water Innovations, there is not a single article focused on PFAS. That wouldn't be exceptional if not for the fact that discussion around per- and polyfluoroalkyl substances has so thoroughly dominated the water space lately. And yet, I penned this as an intro to the edition — just "a tiny bit of PFAS" content — because a small portion of PFAS is of the utmost importance in terms of treatment, policy, and cost.

MORE WATER INDUSTRY FEATURES

-

In the production of adeno-associated virus (AAV) vectors, cell lysis involves challenges addressed through high salt concentrations and a salt-tolerant endonuclease, enhancing titer and infectivity.

-

Reporting noncompliance concerns is crucial to protect research participants, allowing researchers can ensure ethical research conduct and protect the rights and welfare of participants.

-

Learn why the U.S. EPA has recognized granular activated carbon (GAC) as a best available technology (BAT) for a wide range of substances within the same system.

-

Learn why GAC alone may fall short in PFAS treatment—and how utilities can future-proof performance with multi-barrier strategies that tackle short-chain compounds, regulatory shifts, and rising operational risks.

-

This article will explore five common misconceptions about GAC and IX technologies for PFAS removal, helping utilities choose effective, site-specific treatment strategies for contaminated drinking water.

-

Optimizing pDNA production in E. coli requires strategic media selection and scale-up planning. Explore a study that identifies ideal conditions for high-yield manufacturing.

-

Explore how manufacturers can turn sustainability challenges into strategic advantages through smarter energy use, regulatory insight, and emerging innovations.

-

Though new EPA regulations are set to enforce stricter limits on PFAS in drinking water by 2029, millions of students are already attending schools in areas with elevated risk today.

-

Explore how efficient powder-liquid mixing and sterile filtration preserve media integrity and support reproducibility in biopharmaceutical workflows, with promising scalability for larger-volume applications.

-

In this study, the injection precision of an Alliance iS HPLC System was evaluated using four compendial HPLC methods from the USP with challenging method conditions and strict system suitability criteria.

-

Learn about the early history, development, and modern-day applications of jet aerators, highlighting their significance in wastewater treatment

-

Risk assessment is integral to manufacturing processes, particularly in drug production, and having effective containment strategies can help identify potential hazards and ensure worker safety.

-

The rising popularity of vitamin supplements necessitates ensuring product content accuracy. In this study, we demonstrate the ability to achieve the same quantitative results on legacy and newer HPLC systems.

-

Advanced side stream filtration protects sensitive cooling infrastructure in data centers, extending membrane life, reducing water and energy use, and preventing costly downtime caused by particulate-loaded cooling water.

-

Constant vs. Proportional Diffusivity In RSSCT: Choosing The Right Model For GAC Performance Testing

When designing adsorption systems for PFAS removal, utilities and engineers increasingly rely on RSSCTs (Rapid Small-Scale Column Tests) to compare the performance of granular activated carbon (GAC) or other sorbents. One often overlooked yet critical assumption in RSSCT modeling is the choice between constant diffusivity and proportional diffusivity. Though both approaches are valid, selecting the right model can significantly impact how well bench-scale results translate to full-scale systems.

-

This case study demonstrates the effectiveness of a new technology for removing PFAS from well water to below the EPA’s detection limits.

-

The future water utility must embrace open, affordable solutions to unlock the full potential of data. This article will explore examples of open data driving efficiency and innovation.

-

Discover the critical role of formulation buffer composition in stabilizing monoclonal antibodies during tangential flow filtration, a process involving ultrafiltration and diafiltration under high pressure and shear forces.