ABOUT PPG

Filtration Technologies from PPG – Performance-engineered membranes and spiral wound filters

At PPG, we work every day to develop and deliver the paints, coatings and specialty materials that our customers have trusted for more than 135 years. PPG has a long-standing tradition of developing high-quality, innovative and sustainable solutions that customers trust to protect and beautify their products and surroundings.

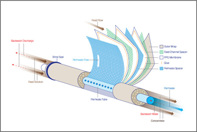

We remain focused on developing solutions to meet the evolving needs of our customers, while collaborating with industry to get ahead of future trends. We recently began manufacturing unique composite single-layer ultrafiltration (UF) and microfiltration (MF) membranes and spiral wound filters for use in the filtration and treatment of industrial process and wastewater as well as electrocoat (e-coat) systems.

PPG’s new highly efficient filtration products are gaining a reputation for delivering higher flux rates and more efficient oil/water separation and suspended-solids removal than conventionally cast polymeric membranes. Additionally, our long lasting membranes can be backwashed and are exceptionally durable, standing up to most oils and chemicals.

CONTACT INFORMATION

PPG

440 College Park Drive

Monroeville, PA 15146

UNITED STATES

Phone: 724-325-5339

Contact: Lisa Walters

FEATURED ARTICLES

-

As water scarcity and energy costs rise, new ultrafiltration membrane technologies deliver higher flux, longer lifespan, and reduced fouling—turning water treatment from a compliance task into an efficiency opportunity.

-

Lisa Walters, Global Segment Manager for PPG Filtration Technologies will discuss the challenges associated with treating oily wastewater generated by diverse manufacturing operations. This wastewater, often difficult to treat for reuse or safe disposal, poses environmental and economic concerns.

-

In this clip from Virtual Water Expo, Lisa Walters from PPG talks about the increased demand for clean water, and how PPG is bridging the gap between supply and demand.

-

Read how advancements in material development have led to microfiltration (MF) and ultrafiltration (UF) membranes that can handle oil-contaminated wastewater without excess fouling.

-

Increasing water scarcity, which results in higher water costs, is pushing manufacturers to reclaim and reuse their wastewater.

-

How new advanced-filtration materials are making headway in treating problematic industrial water streams for reuse or disposal.

-

With infrastructure being such a hot topic these days, it is only fitting that industrial water treatment professionals take a second look at their own infrastructure. Here are some areas where new pressures from the impacts of climate change, population growth, or government regulations can benefit from improved filtration membrane technology approaches.

-

Here are some links and guidelines designed to help utilities change their perspective on water as a low-cost resource of virtually unlimited supply.

-

In many industrial applications, water is not part of the final product but an important process facilitator — for cooling, cleaning, etc. Like energy, it can quickly become a major expense and, therefore, an important target for cost control. As potable water supplies tighten or become increasingly expensive, reuse is becoming a more attractive alternative. Here is some of the information needed to evaluate the opportunities it offers.

-

In Mexico City, few residents have tap water or washing machines and most visit laundromats to clean their clothes. To keep up with demand, most of the city’s laundromats take delivery of fresh water three or four times per day at great expense to facility owners. Virtually none of this water is reused or recycled.

-

An automotive parts manufacturer producing millions of parts per year was seeking to remove cutting fluid/oil and suspended solids from water used in its parts-washing process to enable water recycling and reuse in the parts washer. Successful lab testing and trials enabled the system integrator to win the project and install full-scale systems utilizing PPG’s UF membrane element. Read the full case study to learn more.

-

Environmental regulations and water scarcity have created a need for economical water treatments that increase reuse. This paper will review the new PPG membrane that has a unique composite single-layer microstructure that provides high-flux, excellent separation capabilities and exceptional durability to improve the filtration and recovery of industrial wastewater.

-

Water is essential to numerous industries such as chemical manufacturing, automotive production, oil and gas refinery and power generation, yet the increasing scarcity of this precious resource makes its recovery from these activities more critical than ever.

-

PPG Industries has spent the last four years developing and field testing a membrane-based filtration technology that has arrived in the market as both a flat sheet and a spiral on filter cartridge.