ABOUT HARMSCO FILTRATION PRODUCTS

Established in 1958, Harmsco Filtration Products has manufactured innovative and cost-effective solutions for liquid filtration challenges. With 3 divisions and a global footprint our Made In America, Family Owned Business provides energy savings, proven products, and enduring value. As a pioneer in the filtration industry, Harmsco holds numerous U.S. Patents for innovative filtration technologies while maintaining our focus and commitment on quality and value for the end user.

CONTACT INFORMATION

Harmsco Filtration Products

7169 49th Terrace N.

Riviera Beach, FL 33407

UNITED STATES

Phone: 561-848-9628

Fax: 561-848-0756

FEATURED ARTICLES

-

Advanced side stream filtration protects sensitive cooling infrastructure in data centers, extending membrane life, reducing water and energy use, and preventing costly downtime caused by particulate-loaded cooling water.

-

This article explores various real-world applications of Harmsco’s filtration solutions, highlighting how tailored filtration systems improve water quality, reduce maintenance costs, and enhance operational performance across industries.

-

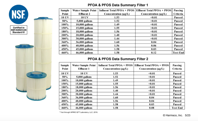

PFOS/PFOA are a group of man-made chemicals that persist in the environment. These chemicals have been used for decades in fire retardant foams and other fire fighting sprays.

-

This article chronicles the inspiring origin story of Harmsco Filtration Products, tracing its evolution from a kitchen workshop to a leader in filtration technology.

-

Pre-filtration is the first line of defense against fouling and is a critical part of the overall desalination process. These systems remove solids that can compromise delicate RO membranes.

-

Water systems are complex, and many things can go awry that can cause a once-compliant plant to fall out of compliance or cause a compliance solution to fail at startup.

-

Smaller water utilities may be in a panic over the EPA's proposed federal limits on PFAS, but there are two reasons for these smaller utilities to remain hopeful.

-

There are a few things that smaller water treatment plants should keep in mind when homing in on the most viable technologies for PFAS.

-

Water Online spoke with Alfredo Rizo-Patron and Cyndi Benson of Harmsco Filtration Products about the factors that create the most problems for these communities as well as cost-effective options for achieving and maintaining compliance.

-

From the growth of contaminants of emerging concern — such as PFAS and 1,4-dioxane — to dwindling water supplies and tighter budgets for capital projects, the ability for municipalities and industry to generate clean, safe water has been a growing challenge across the country.

-

Municipal water utilities throughout the U.S. are increasingly grappling with the need to address PFAS once they are detected in source water. Because standards are a moving target while treatment options are limited and can represent a massive expense, addressing PFAS can be especially challenging for small water systems. The key to finding an optimal solution requires a thorough investigation of the available options.

-

Any Reverse Osmosis System is only as good as the Pre-filtration System protecting it. Pre-filtration is no place to scrimp when it comes to sizing, quality, efficiency and performance.

-

When is the last time you took a moment to stop, and smell your water? A continuous supply of clean and safe drinking water is something that most people take for granted. We rarely go to the tap doubting that the water will be clean and safe.

-

The U.S. EPA’s Long Term 2 Enhanced Surface Water Treatment Rule (LT2) was adopted in 2006 to modify the Safe Drinking Water Act and more tightly control the spread of Cryptosporidium, a microorganism that can cause gastrointestinal infection if ingested. Since its inception, the rule has posed a treatment challenge to utilities that are susceptible to the tiny contaminant. But which utilities are at risk? And how should they approach treatment?

-

For water treatment operators and utility officials, the summer months don’t just mean sunshine, pool parties, and barbecues. The season also brings the peak time for algal blooms, the toxic clouds formed in surface water thanks to increased nutrient contamination and rising temperatures. With rising instances of toxic algae around the country and increased regulations for eliminating it, utilities have had to keep pace.

-

The facility’s Management Team set a goal to reduce their maintenance and operating expenses by greater than 25%. The Management Team researched filtration options available and determined that the Harmsco® Hurricane® Filtration System would meet or exceed their requirements.

-

Discover how Harmsco's Municipal Cartridge Filtration Systems saved a Montana Water District over $1 million.

-

Harmsco® Filtration Products is pleased to offer a solution to the ever increasing blue-algae blooms in water sources. A multi-barrier approach is necessary to physically remove intact (algae and cyanobacteria) before they rupture in the treatment process and then remove extracellular cyanobacteria through adsorption.

-

Harmsco Filtration Products conducted a test to evaluate the performance of the Anti-microbial filter media verses Standard filter media. Two cartridges were compared, both were manufactured with 4 oz filter media, one of the cartridge’s media contained Silver Zeolite fibers which inhibit the growth of biologicals in and on the filter cartridge.

-

An industry expert addresses technology and compliance concerns regarding the U.S. EPA’s Long Term 2 Enhanced Surface Water Treatment Rule (LT2).