ABOUT US

For more than 90 years, Hach has been at the crest of the industry - finding solutions that help you best manage your water. Our analytical instruments and reagents are used to test the quality of water in a variety of industries and markets - from around the corner, to around the globe.

CONTACT INFORMATION

Hach

5600 Lindbergh Dr

Loveland, CO 80538

UNITED STATES

Phone: 970.663.1377

APPLICATION NOTES

-

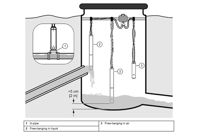

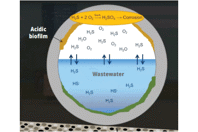

Hydrogen sulfide (H2S) gas in wastewater environments is a familiar concern. But waiting until its odor is detected can be too late to exert as much control over it as desired. Fortunately, a new ability to monitor H2S concentrations — in the liquid wastewater stream, in real time — is advantageous for wastewater professionals in terms of safety, cost, and consumer complaints. Here are four ways to capitalize on that capability.

-

This application note explores how an exclusive sensor has created entirely new ways to address hydrogen-sulfide concerns.

-

This application note explores the importance of maintaining a delicate balance in reverse osmosis systems to protect RO membranes.

-

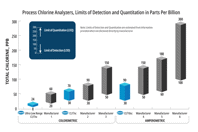

Limits of Detection and Quantitation are key to understanding analytical instrumentation capabilities, especially when non-optimal process control can lead to damage of sensitive equipment due to insufficiently accurate readings.

-

In this application note, explore considerations for achieving more reliable accuracy when quantifying dechlorination results for applications ranging from RO membrane protection to wastewater discharge compliance.

-

Accurate monitoring of oxygen levels in Monoethylene Glycol (MEG) injection solutions is crucial for gas condensate pipelines in the oil and gas industry.

-

This application note explores a test which demonstrated significant improvements in Oil-in-Water monitoring of industrial wastewater in comparison to the weekly grab sample analysis method.

-

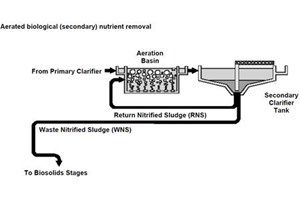

The North Las Vegas Water Reclamation Facility treats an average of 17 million gallons a day (MGD) of wastewater through an advanced nutrient removal process with subsequent membrane filtration. The utility’s process control enables treatment effluent exceeding typical environmental standards and allows discharge to Lake Meade, where it subsequently is withdrawn and fully treated by other facilities for drinking water distribution.

-

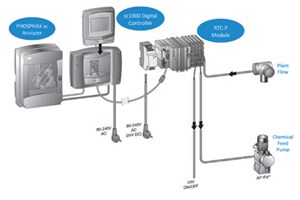

Levels of phosphorus, a chemical element that promotes organic growth, must be controlled in wastewater coming from beverage, food and dairy processing plants. Failure to control phosphorus accurately has a negative impact on water quality and can lead to large fines.

-

Refineries are challenged to properly reuse or dispose of sour water by removing ammonia (NH3) and hydrogen sulfide (H2S) from water through a process called stripping.

-

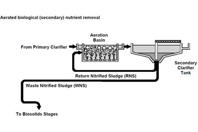

Excess ammonia in receiving waters causes algal blooms that decrease oxygen levels. For this reason, many wastewater treatment plants (WWTPs) must limit ammonia in discharge. Mike Rousey, Hach Company

-

Biochemical Oxygen Demand (BOD) analysis is the test everyone loves to hate—and for compelling reasons.