Water And Wastewater Pipeline Infrastructure Opportunities

There is little doubt that America’s infrastructure is aging, and in some cases, operating well beyond its originally intended lifespan. With labor costs representing up to half of the cost of pipe replacement, the key to cost-effective water and wastewater utility strategies revolves as much around labor-saving installation efficiency as it does around the physical performance of a particular material. Here is a look at historic failure rates, causes, and factors to consider when replacing existing water distribution and sewer networks.

A Historical Perspective

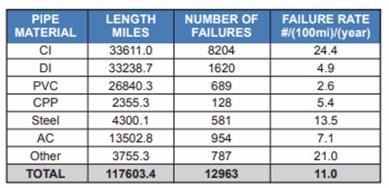

That historical experience reflects not only material performance, but also a combination of factors including age of the infrastructure, soil conditions affecting corrosion, installation flaws, shifting soil, etc.

Something For Every Condition

According to the water main break study, most utilities use multiple types of pipe materials in their water distribution networks. Eighty percent of the utilities in the study combined a range of materials in their water mains — cast iron at 28 percent, ductile iron at 28 percent, and PVC pipe at 23 percent. A relatively low number of utilities (13 percent) avoided ductile iron due to corrosion concerns. Each material type satisfies a range of more favorable and less favorable performance scenarios:

- Cast Iron. This widely used material has shown long life — 100-year to 150-year lifespan — in municipal utility applications, but is currently being replaced by other materials. Ductile iron pipe is the closest alternative in terms of cost and performance.

- Ductile Iron Pipe. Although ductile iron pipe is strong, it can be susceptible to corrosive effects of acidic materials — sewage or exterior soil conditions. Cement mortar interior linings or exterior encasement with polyethylene can help this material withstand those challenges. Zinc-coated ductile iron pipe also aids longevity.

- Concrete Pipe. This material offers durability, strength, and longevity, as long as care is taken not to damage the pipe during installation. Because this rigid material is not highly dependent on support from the soil beneath it, it works well in wet soil environments. Concrete pressure pipe used for water distribution satisfies a broad range of internal pressure and external load conditions and also has a good track record for longevity

- Steel Pipe. Steel has proved its durability in water systems for nearly 200 years. Its ability to withstand high internal pressures and its resistance to pressure surges have made it a choice for large-diameter applications in both water and wastewater applications. It can be lined with various coatings to provide greater resistance to acidic water.

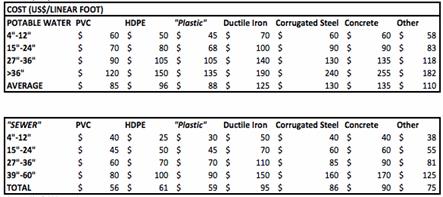

Figure 2. Relative Piping Material Costs. Source: Bluefield Research

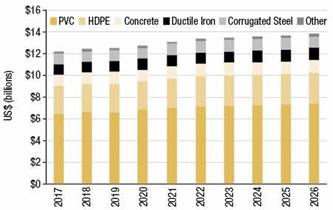

Despite the well-documented historical performance characteristics of those familiar materials, two of the most popular materials in demand today are extruded plastic pipes. According to Bluefield Research, there are significant differences in installation costs depending on pipe material used. For example, medium-sized plastic pipes (PE, PVC) usually cost between $7 (U.S.) and $10 (U.S.) per foot, with installation costs running around $70 (U.S.). Iron, steel, and concrete pipes show higher installation costs, due to the equipment and machinery needed to put them into the ground (Figure 2).

Plastic Pipe Formats Gaining Favor

- PVC Pipe. As a lightweight, durable, and cost-efficient material, PVC pipe has proved its capabilities for decades in water distribution infrastructure. It requires only about 40 percent of the wall thickness of HDPE pipe to deliver the same pressure rating. It is used for both above-ground and underground installations as long as it is not required to withstand high pressures (300 psi) or high temperature (140oF). It is also well-suited for both direct burial and “trenchless” installations. Industry sources cite cost saving as high as 70 percent in replacement applications, when compared to other materials.

- HDPE Pipe. HDPE pipes typically need to have about a 2.5-times-thicker cross-section to deliver comparable pressure ratings to similarly sized PVC pipe. However, they can absorb and dampen shock waves to reduce the impact of surge within an installation. They can also withstand higher pressures at heat-fused joints. The smooth surface practically eliminates pitting and scaling, and retains its hydraulic characteristics throughout a long service life.

Long extruded coils of HDPE require fewer fittings, making installation quicker, easier, and less leak-prone, even in “trenchless” installations. Their flexibility and bending radius, even at cold temperatures, make them compatible with long runs over uneven ground and tolerant of shifting soils as well as earthquake-susceptible zones. Heat-fused joints — including butt, socket, and sidewall joints — are essentially as strong as the original material itself, so they are virtually leak-free. Available in sizes ranging from less than 1” to greater than 60” and with a variety of valve, flange, tee, wye, and elbow fittings, they are easily configurable to a wide range of installations.

- Trenchless Installation Technologies. Plastic pipeline materials are not the only cost-saving opportunities presented by infrastructure upgrade activities. Because trenching operations involve expensive aspects of equipment and manual labor costs, plastic piping alternatives compatible with trenchless installation provide additional cost-saving alternatives where practical.