Sludge Sampling For Polymer Selection — Critical For Project Success

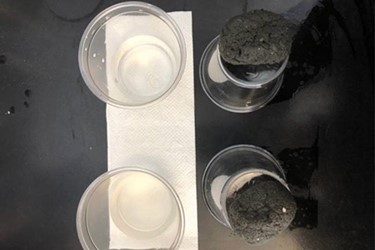

Polymers — the chemicals used in wastewater to thicken sludges and facilitate the removal of free water — are critical to the operational efficiency of sludge thickening equipment. Unfortunately, it’s common practice at treatment facilities to order and install equipment before even considering what the ideal polymer might be for the sludge produced at the specific plant. Once the equipment is installed, startup becomes a lengthy activity of experimentation with a variety of polymers to find the best fit. This flawed process is time consuming, disruptive to plant operations, and can become very costly in both the short term as well as drive up the long-term operational costs of the sludge thickening equipment.

When undertaking a trial-and-error approach for polymer selection, the operations staff, consultants, or contractors must procure a variety of polymer types to run the test. This step in itself is both costly as well as a significant logistical exercise when taking into account delivery and storage requirements. Once all the materials are onsite, the process of testing for the best fit can mean several days of hit-and-miss attempts. It can also lead to improper information for selecting a final polymer. One common error is choosing a polymer that is cheaper per pound but requires significantly more product to produce the desired result.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.