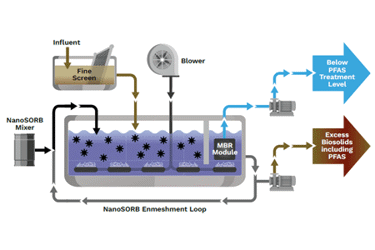

NanoSORB™ Membrane Bioreactor (MBR)

ECT2’s research and development team has developed a novel technology called NanoSORBTM that leverages the activated sludge process tankage for PFAS removal.

ECT2’s research and development team has developed a novel technology called NanoSORBTM that leverages the activated sludge process tankage for PFAS removal. We have demonstrated the technology in partnership with Ovivo’s SiC MBR product, and the resulting effluent turbidity (water clarity) is extremely low and total suspended solids are non-detect. The new process creates a single PFAS-laden residual stream well suited to future PFAS destruction pairing. Once a proper dose is established for the waste stream, effluent concentration levels have shown consistent removal of PFAS below the project treatment objective of 20 ng/L.

Benefits

- Leverages high surface area and extended contact times allowing for greater removal of PFAS, TOC, COD and other contaminants of concern which results in more efficient use of media

- Removes a wide range of contaminants to low levels including PFAS, recalcitrant compounds, and biodegradable organics

- Helps prevent toxic shock, especially to sustain nitrification

- Faster kinetics which reduces tankage needs and footprint

- Enhances breakdown of slowly biodegradable organics, removes non-biodegradable organics

- Enhanced mixed liquor filterability, increases flux, reduces membrane cleaning requirements (reduces filter size, capital cost)

- Improved viability of MBR microbial communities with the reduction of toxic components, such as heavy metals, from the waste stream

- Provides benefits of biological and adsorptive treatment mechanisms in a single process