ABOUT ECT2

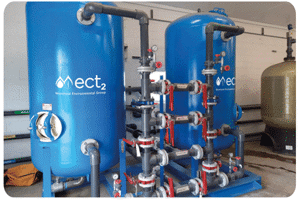

ECT2, a Montrose Environmental Group company, is a leading provider of novel technologies for removing difficult-to-treat contaminants from water and vapor using a proprietary, cost-effective approach that leverages the properties of synthetic resins to enable efficient analyte removal and on-site regeneration. With successful applications deployed around the world for contaminants including 1,4-Dixone and per-and polyfluoroalkyl substances (“PFAS”) in water, ECT2’s systems have achieved industry-leading uptime and deliver contaminant removal well below specified limits. Due to this advanced technology, ECT2 has been a recognized PFAS treatment leader since 2016. For more information, visit www.ect2.com.

CONTACT INFORMATION

ECT2

125 Industrial Way

Portland, ME 14103

UNITED STATES

Phone: 614-987-2610

Contact: Philip Alia