| Smith & Loveless - Protecting Water. Protecting People™ | ||||

|---|---|---|---|---|

|

Smith & Loveless offers a diverse array of water and wastewater treatment and pumping system solutions for the world's water problems. Additionally, we deliver unique technologies and consumables for mineral processing. Please browse our many solutions to learn more about our product offerings. |

||||

|

|

|

||

| S&L Redesigns TITAN MBR™ | Hospital Upgrades Submersible Pump to S&L Wet Well Mounted Pump Station | Guidelines For Grit Pumping And Piping | ||

CONTACT INFORMATION

Smith & Loveless, Inc.

14040 Santa Fe Trail Drive

Lenexa, KS 66215

UNITED STATES

Phone: 913-888-5201

Fax: 913-894-0488

Contact: Darby Ritter

FEATURED ARTICLES

-

The Hydraulic Institute (HI) bestowed its highest individual honor on Smith & Loveless Inc. vice president of engineering Rodney Mrkvicka, P.E., when he was named HI’s 2021 Member of the Year. The award was conferred to Mrkvicka at HI’s Annual Meeting in Orlando in March.

-

Smith & Loveless Inc., the global leader in advanced grit removal system technologies, announces its next-generation grit chamber innovation, PISTA® INVORSOR™, designed to capture industry-best ultra-fine grit particles down to 75-micron particles across all flow conditions.

-

Explore stories of real success with wastewater treatment at oil/gas refineries, and LNG and chemical plants.

-

One municipality keeps detailed records on all repair and maintenance work orders and costs for its 53 pump stations, some submersible and some S&L Wet Well Mounted. A 12-year study of the data revealed nearly 56 percent lower operating expenses for the S&L stations compared to submersibles—a differential of nearly 30 labor hours and $2,750 per station per year!

-

When a major pork producer sought cost-effective pumping solutions to one of its Kansas facility's wastewater systems, the search led to the installation of a Smith & Loveless above-grade pump station.

-

The TITAN MBR helped a winery become the first ever to earn a LEED Platinum Certification for new construction in 2018 (Leadership in Energy and Environmental Design).

ABOUT SMITH & LOVELESS INC.

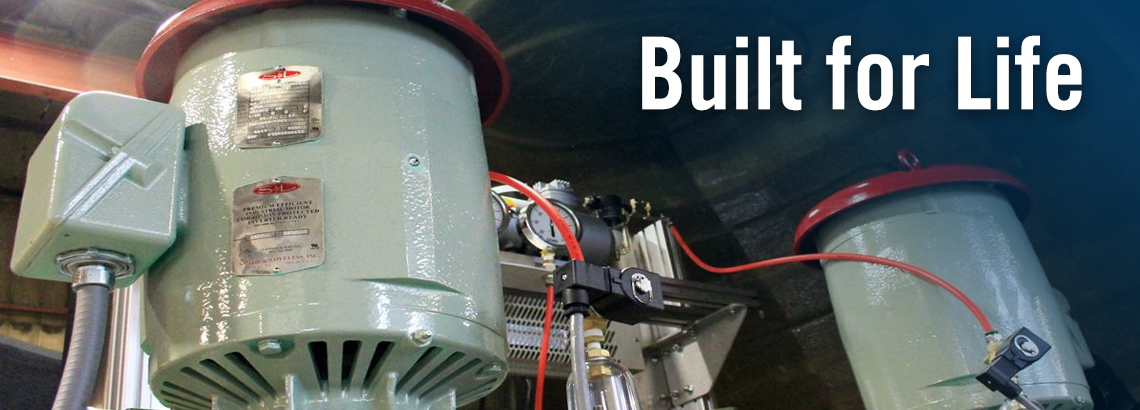

For more than 70 years, Smith & Loveless' pre-engineered water and wastewater treatment and pumping systems have paved the way for municipalities, developments, industry, governmental, and military facilities. Smith & Loveless' energy-efficient and durable systems deliver unrivaled life-cycle cost savings.

To get there, our company has grown steadily from the early days of our original founders, Alden Smith and Compere Loveless, to a multi-facted corporation comprised of sales offices, production facilities and affiliated companies serving diverse markets all over the world.

S&L Releases New Pumping Systems Design & Spec Catalog

The catalog includes the latest specifications, technical drawings and literature for all pumping systems and related products manufactured by Smith & Loveless, Inc. Informational sections outline the need for pumping systems and the unique benefits offered by Smith & Loveless, Inc. products.

The catalog includes the latest specifications, technical drawings and literature for all pumping systems and related products manufactured by Smith & Loveless, Inc. Informational sections outline the need for pumping systems and the unique benefits offered by Smith & Loveless, Inc. products.

Among the features in this catalog are newer models of 6” X-PELLER® pump impeller (with the corresponding curves and specifications), “SAWS” Station Advance Warning System, and StationComm™ 2-Way Text communication for Smith & Loveless pump station control systems.

Aside from the printed catalog, Smith & Loveless, Inc. offers a digital version, which also contains color brochures, videos and a ‘product showcase’ that summarizes each product. Easy to navigate, it connects users directly to the information desired in an efficient manner.

To request your copy, Click below