ABOUT PANAMETRICS, A BAKER HUGHES BUSINESS

Panametrics, a Baker Hughes Business develops solutions for moisture, oxygen, liquid flow, and gas flow measurement, with proven technologies that are known across many industries, including oil and gas.

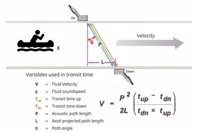

Panametrics entered the ultrasonic flow market with a gas flow meter more than 60 years ago. Since then, the Panametrics brand has been known for its high-technology inline and clamp-on flow meters that handle the toughest applications and environments.

Panametrics, a Baker Hughes Business is a division of Baker Hughes. We are an energy technology company. We are taking energy forward – making it safer, cleaner and more efficient for people and the planet.

Panametrics’ flow meters and oxygen analyzers can help your water treatment facility to get the most out of challenging operations through innovative technology.

Our goal is help water and wastewater operators optimize profitability by preventing downtime and improve efficiency.

Our flow meters and oxygen analyzers can improve accuracy and enhance reliability with on-demand readings and tablet to transmitter communication and reduce your maintenance costs.”

E-BOOKS

-

In this e-book, learn how Panametrics technology is providing solutions for a variety of wastewater operation challenges, from measuring wastewater flow in iron pipes to tracking potable water leaks.

CONTACT INFORMATION

Panametrics, a Baker Hughes business

1100 Technology Park Drive

Billerica, MA 01821

UNITED STATES

DATASHEETS

APPLICATION NOTES

-

A hydroelectric power plant in Türkiye needed to establish a system for real-time monitoring of water consumption and turbine performance to enhance its operational efficiency. Crucially, the State Water Authority also required continuous, 24/7 remote access to water usage data for supervisory and regulatory compliance.

-

A municipal wastewater plant in North America sought a reliable flow measurement for one of their key wastewater lines. The existing dual-channel ultrasonic flowmeter from a competitor had consistently failed to provide accurate readings.

-

Read about a desalination plant that was in need of a practical verification methodology for permanent and/or temporary (portable) solutions on large pipes.

-

Late last millennium, Panametrics installed a model 6068 liquid clamp-on flow meter for the measurement of water in Kinlochleven Hydro Power, a hydroelectric power plant in Scotland, to monitor turbine generator performance.

-

A water management company in Serbia used Panametrics' ultrasonic flow meter technology for stormwater management, ensuring reliable measurement and accuracy in challenging conditions. The technology allowed for live monitoring of water transfer and reduced the risk of flooding.

-

A power company was concerned with the in-line ultrasonic flow meter that was showing unstable results. Learn about the solution that they chose to address this issue.

-

A global engineering company realized that their leak identification methods were time consuming and expensive, and so began to explore alternative solutions, such as ultrasonic flow meters.

-

Concerned about the volume of water leakages throughout their network, a Swedish water authority turned to Panametrics flowmeters to map their municipal water network -- enabling quick leak identification and fixes.

-

Major multinational food and drink processing company requested support to validate the performance of existing electromagnetic flow meters, that were failure-prone, in their water treatment plants.

-

A Food & Beverage bulk manufacturer of tomato paste, tomato ketchup, evaporated milk, sterilized cream, hot sauce, full cream, milk powder, oats, cornstarch, and custard powder.

-

The company that is active in the food industry collects and processes animal by-products but also waste edible oil, biodegradable kitchen and canteen waste. These products are recycled to proteins and technical fats and purified oils.

-

This customer supplies district heating and electricity for the region of Sønderborg. For one of their waste applications a MAG meter failed within 6 months, and was successfully replaced with a Panametrics Aquatrans AT600.

-

Different flow meter technologies were used in this geothermal power plant to monitor and measure brine. However, these traditional technologies failed. That’s where Panametrics PT900 Portable Ultrasonic Flowmeter was able to help.

-

A municipal association needed to understand if wastewater was being equally distributed across two cast iron pipes within its wastewater treatment plant. Learn how clamp-on ultrasonic measurement helped successfully measure the flow.

-

In wastewater treatment, aerobic digestion enables plants to increase their capacity by injecting oxygen into the wastewater head space.

-

Stockholm water company produces biogas from their wastewater facility which feeds Scandinavian Biogas for energy production. As they need to accurately meter what they sell to the energy facility they used a project contractor firm to engineer and define the best solution for the project.

VIDEOS

-

Watch our on-demand webinar to learn how to achieve reliable and accurate measurements on your water and wastewater operations. Panametrics’ flow meters and process analyzers can help your water treatment facility get the most out of challenging operations through innovative technology. Our goal is to help water and wastewater operators optimize profitability by preventing downtime and improving efficiency.

-

Each year, livestock produces billions of tons of waste and is estimated to reach at least 5 billion tons per year by 2030. The USA processes approximately 34 billion gallons of wastewater every day. Wastewater treatment plants produce biomethane by produce biogas.

FEATURED ARTICLES

-

Flow, pressure, and temperature are the most important units of measurement when monitoring or controlling fluids in pipes. They are early indicators for problems that can have major implications for the overall business.