ABOUT EBAA IRON

EBAA Iron, Inc. is an industry leading manufacturer of external pipe joint restraint devices that are specifically designed for use on pressurized or non-pressurized waterworks piping systems. Since 1964, EBAA has been a proud privately-held and family-owned N. American based company currently Headquartered in Eastland, TX.

The guiding principles of our founder, Mr. Earl C. Bradley, has continued to lead us in providing innovative piping products primarily for use in the water and wastewater industries. EBAA products are designed and engineered to not only save time and money from their initial date of installation - but more importantly, our products are designed with the intent that they must also protect and ensure the long-term integrity of the piping system.

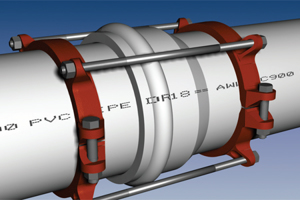

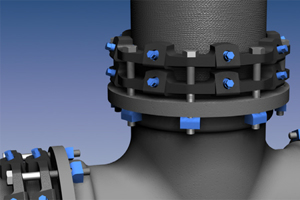

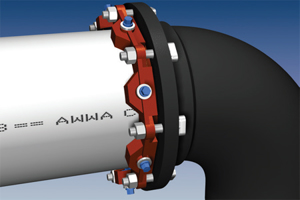

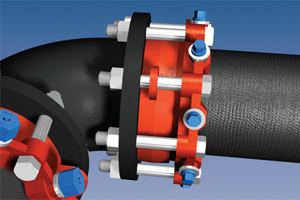

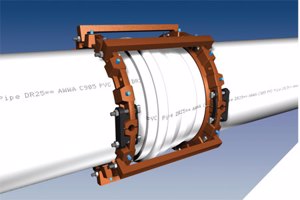

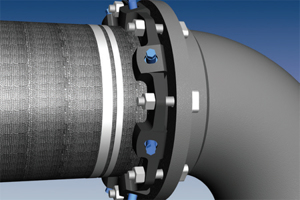

EBAA is the original manufacturer and patent holder of the world famous MEGALUG® Mechanical Joint Restraints, the MEGAFLANGE® Restrained Flange Adapter, the MEGA-COUPLING® Restrained Pipe Coupling and the wide array of FLEX-TEND® Flexible and/or Expansion Joint family of products.

EBAA is also proud to proclaim that all of its pipe restraint products are 100% MADE IN USA - 100% of the time, every time!

CONTACT INFORMATION

EBAA Iron

P.O. Box 857

Eastland, TX 76448

UNITED STATES

Phone: 800-433-1716

Fax: 254-629-8931

Contact: Rick Rackow

FEATURED ARTICLES

-

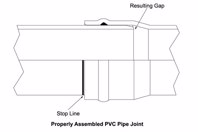

There are many different joints that can be found on waterworks pipeline components. This paper focuses on the three most common joints.

-

Sean Schaefer from EBAA Iron sits down to discuss the founding of EBAA 58 years ago and how the company has grown.

-

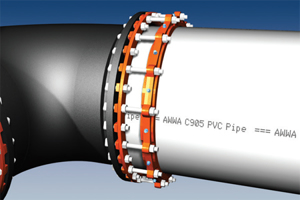

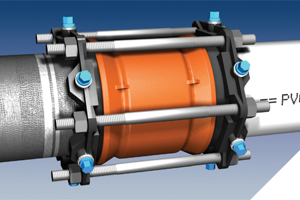

The 2000PV is a restraint for PVC pipe and the standardized mechanical joint. This product is the result of years of testing and evaluation and its performance has been proven by thousands of hours of proof tests, as well as third-party evaluations. This report describes the 2000PV through the 12" size.

-

Water and wastewater piping come in a variety of materials, joints, and diameters. They can meet a multitude of demands and needs for the country's infrastructure.

-

The argument has been used that PVC pipe is delicate and can’t be subjected to any kind of loading. In EBAA's years of testing we have found that is not the case at all. PVC can take an extreme amount of strain.

-

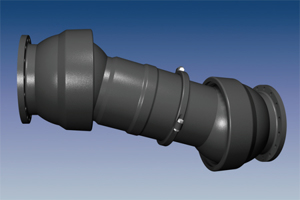

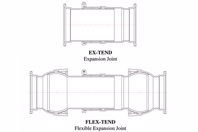

Flex-Tend flexible expansion joints have a proven record of providing protection for pipelines subject to subtle or sudden movement. As with all products used in the water and wastewater industry, protection is optimized with the selection of the proper assembly incorporated into a sound design. This paper is intended to provide assistance in both of these areas.

-

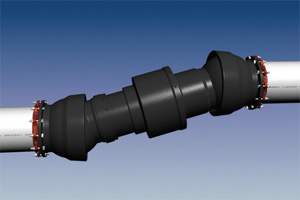

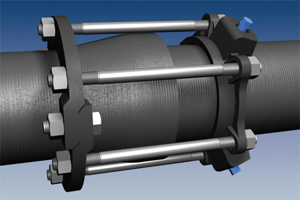

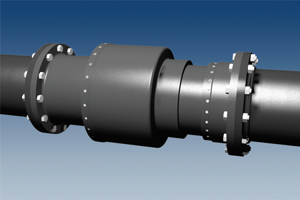

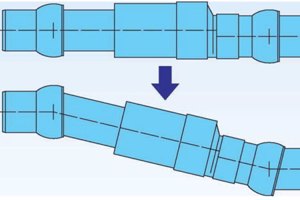

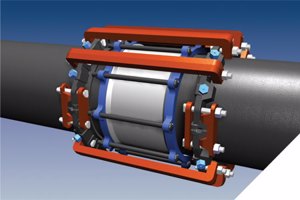

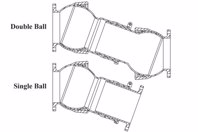

There are numerous configurations of flexible and expansion joints available to the design engineer. They include bellows joints, flexible hoses, bolted-mechanical couplings, and ball joints. In 1989 EBAA Iron, Inc. introduced the FLEX-TEND® joint (FT) flexible expansion joint product into the US market. Constructed of ductile iron, the product is comprised of two ball joints joined by an expansion joint. For the first time one product was available to protect pipelines and pipeline connections from differential movement resulting from seismic activity and soil expansion/contraction in areas of poor soil support, frost heave, and transitions from stable to unstable areas.

-

FLEX-TEND® flexible expansion joints are designed to protect structures and pipelines from differential movement whether this movement is earthquake induced or the gradual motion of soil subsidence. This bulletin offers a concise listing and discussion of the important features and materials of the double and single ball assemblies.

-

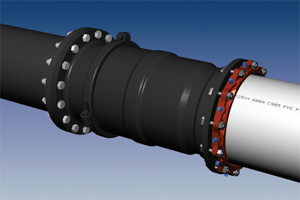

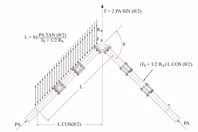

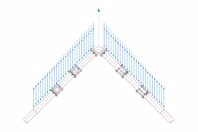

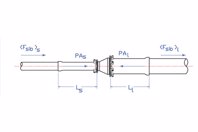

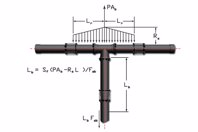

In the last forty years, a quiet revolution has occurred in our industry. This revolution is the result of new generations of joint restraint products that make it possible to quickly and safely restrain fittings at bends, dead ends, tees, valves, and reducers without the need for concrete thrust blocks or tie rods. These joint restraint products turn the pipeline into its own thrust block. The key to utilizing these new products is the understanding and proper application of the pipeline restraint design theory.

-

The Merriam-Webster Online Dictionary defines traceability as “a: to follow the footprints, track, or trail of b: to follow or study out in detail or step by step… c: to discover by going backward over the evidence step by step … d: to discover signs, evidence, or remains of”. At EBAA Iron traceability allows you as the end user or us as the manufacturer to go backward into the production process and discover the signs that reveal the casting properties to the base level.

-

The question often arises “Can you really eliminate thrust blocks using joint restraint?” This bulletin will provide you with the information needed for you to realize the answer to that question is “yes”. For many years, thrust blocks have been successfully used in distribution systems all over the world. Thrust blocks, however, are not without limitations.

-

These equations and soil parameters are an effort to provide the piping system designer with conservative techniques and parameters for the design of underground restrained joint piping systems.

-

This bulletin describes the restrained length calculations for dead ends, valves, reducers, and sleeves with a discussion of several situations where economics and other factors may favor an alternate restraint method.

-

There are numerous fitting combinations and configurations that are used in the everyday construction of pressurized water lines. This report describes vertical offsets, tees, and using joint restraint products to simplify their installation. The use of joint restraint products virtually eliminates thrust blocks and tie rods.

-

Of particular interest when it comes to bridges is the locating of pressurized water lines on and under bridge structures. Pressurized pipelines can present a number of unique challenges to the design engineer and utility owner.

-

Connections bulletins PD-1 through PD-4 discuss some of the specific applications of the design of a properly restrained pipeline. PD-2 specifically addresses horizontal bends and the various parameters involved in the design process. PD-3 applies those parameters to the design of vertical offsets and tees. Finally, the design of reducers, dead ends, and miscellaneous fittings is discussed in PD-4. This bulletin delves into a more detailed discussion of the bearing and frictional resistance forces at work to balance thrust forces generated in pressurized pipelines. To see how this information relates to the various pipeline elements, please refer to the other Connections bulletins.