ABOUT ATLAS COPCO

Atlas Copco is a global leader in innovative compressed air, gas solutions, and blower technology, serving industries with cutting-edge equipment designed for efficiency and sustainability. In the U.S., Atlas Copco supports businesses with a wide range of compressors, vacuum solutions, and industrial blowers tailored to diverse applications, from manufacturing to wastewater treatment. With a focus on energy savings and reliable performance, the company delivers world-class products backed by expert service and local support. Learn more about their solutions here.

CONTACT INFORMATION

Atlas Copco

300 Technology Center Way, Ste. 550

Rock Hill, SC 29730

UNITED STATES

FEATURED CONTENT

-

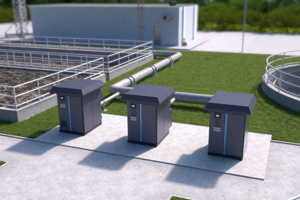

As the operator of a wastewater plant, you may already have realized that not all blowers are alike. Therefore, one of the biggest decisions you have to make is which one is the optimal solution for your requirements.

-

Reliability is especially important in the wastewater treatment sector. One is that the blowers have to dependably operate in conditions that are often very harsh.

-

The key to lowering your operating costs might be changing a few or more air blowers from your blower installation. Is it time to replace your equipment? Let’s check!

-

Efficiency is the name of the game for modern wastewater treatment plants. Unfortunately, many facilities were built decades ago and are becoming increasingly expensive to operate. Therefore, you may be looking for a way to upgrade your wastewater treatment plant to meet the latest standards.

-

The municipal wastewater treatment plant in Port Washington, Wisconsin, is located on the picturesque shore of Lake Michigan, so it’s essential that their plant performs as designed.

-

Oil-free blowers are an essential element of municipal and industrial wastewater treatment facilities, where they are utilized to power a variety of applications. Here are 8 of the most common processes/applications fueled by blowers.

-

Wastewater treatment plants face the ongoing challenge of efficiently processing wastewater from various sources, including residential, commercial, and industrial sectors, to mitigate pollution and safeguard environmental health.