Xylem's Leopold Oxelia™ for Drinking Water Applications

Biological and chemical contamination in drinking water poses a significant public health risk and plant operators require a treatment system that allows them to produce a safe and reliable supply of clear, good-tasting and biologically-stable finished water with the lowest concentrations of non-desired substances.

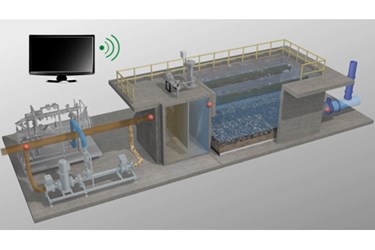

Xylem’s Leopold OxeliaTM oxidation-enhanced biologically active filtration system is a multi-barrier solution employing a variety of flexible technologies for disinfection and oxidation coupled with biofiltration. The process steps are matched and controlled by a dedicated set of online analyzers that feed into an integrated control system to help maximize the synergies between the process steps and optimize operations.

As the issue or concern with biological and chemical contaminates will vary from utility to utility, the OxeliaTM system allows for customer specific designs. The tailored approach helps customers achieve the required treatment goals today with the most efficient and cost effective solution as well as proactively prepared for future regulations.

The oxidation step has several options for design. These include ozone, ozone-based Advanced Oxidation Processes (AOP) or UV-based AOP. For example, if water sources experience pollution with taste and odor compounds and other micro pollutants (e.g. pesticides and pharmaceuticals) all year round, the ozone-based AOP should be considered. If water sources experience seasonal contamination with taste and odor compounds plus a high disinfection credit is required, the UV-based AOP should be considered.

The power of the selected oxidation step is to break down chemical pollutants such as 2-MIB and Geosmin (Taste & Odor), pharmaceuticals, pesticides and other industrial chemicals that can contaminate drinking water sources. The oxidation step also disinfects the water and achieves the required disinfection credit.

Then, naturally occurring microbes attach to the subsequent biological active filter to provide free aerobic biological treatment of the partially oxidized organic carbon for the destruction of total organic carbon (TOC), trace contaminants, and oxidation by-products (e.g. THMs, NDMA, AOC). Thus, the filter retains not only impurities such as particles in physical way, but also delivers the finished water with a low carbon load even in case of raw water quality deterioration.

After several years of in-house testing, the Leopold Oxelia system was pilot tested intensively with the Public Utility Board (PUB) in Singapore. The system is designed to optimize OPEX and CAPEX costs while helping to reliably deliver safe drinking water for today’s and future regulations.