Wastewater Treatment Facility Resolves RTO Siloxane Clogs, Reduces Downtime With More Effective Structured Media

Jacksonville, Fl — Koch Knight LLC, a leading innovator in corrosion proof materials and environmental heat transfer equipment, announces the continued success of its FLEXERAMIC® Structured Media installation in three cells of the JEA's (formerly the Jacksonville Electric Authority) Buckman Regional Residuals Biosolids Treatment Facility RTO unit. RTOs (Regenerative Thermal Oxidizers) are instrumental in processing waste-gas from WWT facility dryers, though they often become clogged with silica powder, a by-product of the siloxane found in wastewater. With an alternative RTO structured media from Koch Knight, the Buckman WWT facility has seen significant reductions in downtime and energy costs associated with siloxane clogs and unit cleaning.

Jacksonville, Fl — Koch Knight LLC, a leading innovator in corrosion proof materials and environmental heat transfer equipment, announces the continued success of its FLEXERAMIC® Structured Media installation in three cells of the JEA's (formerly the Jacksonville Electric Authority) Buckman Regional Residuals Biosolids Treatment Facility RTO unit. RTOs (Regenerative Thermal Oxidizers) are instrumental in processing waste-gas from WWT facility dryers, though they often become clogged with silica powder, a by-product of the siloxane found in wastewater. With an alternative RTO structured media from Koch Knight, the Buckman WWT facility has seen significant reductions in downtime and energy costs associated with siloxane clogs and unit cleaning.

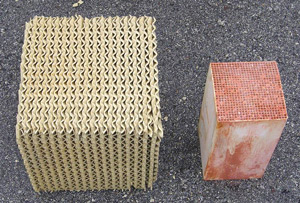

The Buckman WWT facility, which processes wastewater sludge into fertilizer, sought to replace the traditional monolith blocks in its dryer's RTO in July 2005 when perpetual siloxane clogging problems threatened the productivity of the unit. Upon consulting RTO experts from Koch Knight, JEA operators decided to install FLEXERAMIC Type 28 Structured Media, composed of vertically aligned corrugated ceramic sheets, in one of their three cells. After six months of running the unit with both types of blocks, the JEA operators saw that the cell with FLEXERAMIC Type 28 Structured Media provided greater air-flow, and cleaned effectively and in less time than their traditional packing. The JEA has since replaced the packing of the remaining two cells with FLEXERAMIC Type 28 Structured Media as well.

"There are several variables that affect air flow in RTOs," said Scott Schulz, director of by-product services at JEA. "But from the common-sense, day-to-day operation and maintenance of this facility, we are convinced that the FLEXERAMIC Structured Media blocks are superior to the old-style blocks. We went from cleaning our RTO cells about every three weeks to about every four months."

"There are several variables that affect air flow in RTOs," said Scott Schulz, director of by-product services at JEA. "But from the common-sense, day-to-day operation and maintenance of this facility, we are convinced that the FLEXERAMIC Structured Media blocks are superior to the old-style blocks. We went from cleaning our RTO cells about every three weeks to about every four months."

JEA operators have also noticed a reduction in the usage of gas as the facility's RTO has become more energy-efficient. Though FLEXERAMIC Structured Media has less surface area than traditional packing, the greater airflow, improved distribution and reduced clogging actually results in a more resourceful usage of its surface area and a lower pressure drop.

JEA is a publicly owned water, sewer and electric utility in Jacksonville, Florida. JEA's water system serves more than 240,000 water customers and 186,000 sewer customers, or more than 80 percent of all water and sewer utility customers in its service area. The Buckman WWT facility is JEA's largest regional sewer plant and treats an average 28 million gallons of sewage each day with a total capacity of 52.5 MGD.

SOURCE: Koch Knight LLC