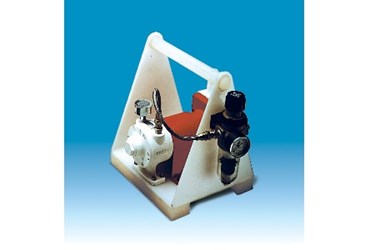

Vanton Air-Driven Flex-I-Liner Pump Safely Transfers Volatile Chemicals, Gases

Plant managers who are responsible for safely transferring volatile chemicals and/or gases can now do so using the air-driven Flex-I-Liner pump from Vanton Pump and Equipment Corp. This peristaltic type rotary pump is designed for use in remote areas where electricity is unavailable or when a spark may ignite the substance being pumped. Providing gentle pumping action, it operates wet or dry and can be supplied with rotary vane air motors.

The fluids or gases pumped by the air-operated Flex-I-Liner do not come in contact with any metallic surfaces which would greatly reduce a pump’s service life. Instead, volatile fluids and gases only come in contact with the pump’s thermoplastic body and its elastomeric liner. These inert materials and are not impacted by corrosive, abrasive and/or other aggressive fluids handled by the pump.

Designed to eliminate shaft seals, stuffing boxes and other common sources of leakage, this Vanton pump can be supplied with reversible operation to allow for changing flow direction. Its motors develop up to 2000 rpm on 90 psi and control of the air motor drive allows for varying flow rates within +/-5 percent. No special tools are needed for maintenance.

About Vanton

Vanton Pump & Equipment Corp. manufactures chemically inert, thermoplastic pumps and systems that solve fluid containment, dosing and transfer problems. The company’s products feature wet-end components constructed of injection-molded, homogenous thermoplastics. These inert thermoplastics are resistant to acids, caustics, salts, chlorides, halogens, and other aggressive or abrasive chemicals. Unlike metal pumps, there is no acceptance ofannual corrosion levels.

In addition, thermoplastic pumps will not wick or abrade as plastic-lined pumps, elastomeric-lined pumps and fiberglass reinforced plastic pumps may.

Vanton pumps are engineered to individual requirements and are also available in a variety of vertical and horizontal configurations including: bearingless, ANSI B73.1, cantilevered, integral-motor shaft, Vortex, DIN, and more. The company also supplies sump pumps to 28 feet in length.

Each Vanton pump undergoes thorough testing before shipping and is verified to perform to the customer’s desired flow and head specifications.

With a worldwide network of factory sales and service representatives, Vanton pump users are assured of timely, knowledgeable support service wherever they are located. For more information , visit www.vanton.com.

Source: Vanton