Utilizing The Potential Of Wastewater: From Energy Consumer To Energy Producer

By Frederikke Rørvang Mikkelsen and Jens Enevoldsen

Producing energy and being more energy efficient are not only economically wise decisions, they also demonstrate local responsibility, create a sense of pride among employees, and reduce the global carbon footprint.

With pumps, aeration diffusers, motors, and blowers running 24/7, the water sector naturally accounts for a great deal of total energy use and thereby greenhouse gas (GHG) emissions. From a U.S. perspective, the EPA estimates that the U.S. water stream accounts for 45 million tons of GHG annually, with energy use corresponding to 2 percent of national consumption. On an economic level, energy consumption related to operating wastewater and water plants, on average, accounts for approximately 35 percent of a typical U.S. municipality’s energy budget.

Initiatives to save energy and thereby reduce operational costs take many forms — from investing in highly efficient equipment such as variable frequency drives (VFDs), efficient blowers, better controls with mechanical mixers, etc. to switching to LED lighting and sensors at the facility’s buildings.

However, saving energy will only take you so far. To become energy-neutral and then to start producing energy, some utilities even install solar panels to provide renewable energy onsite — but there lies an immense, and often unused, opportunity for plants to generate energy and heat through the intelligent use of carbon. Multiple utilities have found a way to utilize this opportunity and have realized both economic and environmental impacts.

The Danish Way: Produce More Than You Use

The Danish water sector is among the most sustainable in the world, and, before 2030, the water sector aims to be climate-and energy-neutral. The ambitious goal is a part of the climate initiative by the Danish government, which has pledged to reduce the country’s carbon dioxide (CO2) emissions 70 percent by 2030.

However, the journey toward sustainable wastewater management has been in progress for years. Aarhus Vand and VCS Denmark are two of the progressive Danish utilities that have been working strategically to develop energy-neutral utilities for decades. It all started with a challenge to save energy and become more efficient, and now, after years of continuous work, Aarhus Vand is able to announce that GHG emissions are now 77 percent lower than in 2008.

“At our WWTP [wastewater treatment plant] in Marselisborg, we now produce 50 percent more energy than we use. By implementing energy-efficient solutions and producing biogas from the sludge, we are almost able to cover the energy consumption for the whole water cycle from the groundwater extraction to pump stations, water distribution, and wastewater treatment,” Claus Homann, chief operating officer at Aarhus Vand, said.

Per Henrik Nielsen, project director at VCS Denmark, recognizes the initiatives made at Aarhus Vand, as they too have been working diligently to optimize their operations for decades. Today, VCS Denmark has already achieved neutrality as a water and wastewater utility, including office buildings, vehicles, etc. Like Aarhus Vand, they are not adding solar, fats/oils/grease (FOG), or other external carbon sources into the mix.

He points out that the urge to become a sustainable utility stems from three factors: economy, responsibility, and curiosity.

“First of all, it has to be a good investment seen from an economical perspective. Second, we have a responsibility as a utility to provide healthy and drinkable water for our community. And third, we have to keep empowering our employees and giving them an urge to optimize and do better, instead of just meeting the requirements. Innovation and curiosity are key factors in driving a sustainable utility — but for those utilities where sustainability is not the goal, then doing better, at least, should be,” Nielsen explains.

Since 2014, U.S. utilities have been visiting Denmark through the Danish Water Technology Alliance’s outreach program. Denmark is not the U.S., but the experience is clear — best and next practices from Denmark are also applicable in the U.S.

Downers Grove: A Rewarded Net-Zero Facility In Illinois

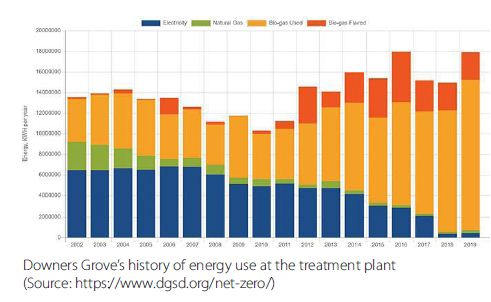

One of the U.S. utilities that has participated in a delegation tour to Denmark is Downers Grove Sanitary District in Illinois — and they have already seen the benefits of saving and producing energy. Twelve years ago, they started what turned out to be a journey toward being a net-zero facility when high-efficiency turbo blowers and fine-bubble aeration diffusers were installed at the plant.

“The most obvious perk is the money saved on the plant’s electricity bills. Additional perks are the good public perception of our district and the employee pride and morale. We received grant money from the Illinois Clean Energy Community Foundation for being a net-zero-energy facility. As part of the grant program, we created a Net-Zero Education Center, which will be used during tours of the plant to teach students as well as the public about energy efficiency,” Amy Underwood, general manager at Downers Grove Sanitary District, explained.

Apart from implementing the energy-efficient solutions, one of the main components in reducing the energy use and GHG emissions has been the installation of cost-efficient Danish combined heat and power (CHP) units to start producing energy. Running the CHPs has changed some of the focus from the wastewater treatment, as some of the mechanics have been trained to maintain and operate the CHPs with a focus on co-digestion and gas cleaning. The transformation has presented a few initial challenges, but in the end, Underwood emphasizes that the changes have been worth it on several levels.

“The employees’ mindsets changed for the better after we had hard numbers on how much electricity we can save and produce and the resulting money we are saving. Giving tours to the public also helped with the employees’ mindsets, as visitors are quite impressed with co-digestion and turning grease into electricity. Overall, it’s a lot more work, but now there is a sense of pride about the great things that we are doing,” Underwood stated.

Data-Driven Operations And Control Systems

In the process of becoming energy-neutral facilities, the three utilities all mention data control and automation as important tools. Measuring the process at all times presents insights that are invaluable in controlling the operations. Through the insights, it is possible to adjust operations and make sure that you do not use more energy than you actually need. At Downers Grove, they have implemented multiple data-driven solutions to measure the process at all times and automatically adjust the operations to meet the requirements.

“The duty raw sewage pumps operate on variable frequency drives. The plant has high-efficiency turbo blowers providing air to the aeration tanks. The blower speed is controlled using feedback from DO [dissolved oxygen] probes and an ammonia analyzer to ensure that we are only providing as much oxygen as required for the process. Some of the return activated sludge pumps are on VFDs, and some plant equipment switches between high- and low-flow modes,” Underwood explained.

The three utilities have all increased automation in their operations as a part of the strategic work with sustainability. However, they highlight that it has more benefits than just being sustainable — because, as they have started to control their operations through data-driven decisions and have optimized their processes to become energy-neutral, they are also able to cut operational costs. Furthermore, in times such as these with a global pandemic, they have been able to maintain operations with a limited amount of staff due to the automatized operations.

Actually, according to Nielsen, data is not just key — it is a prerequisite.

“Operating your plant without data is like driving a car in the night without the lights on. You need the light to maneuver your car securely on the road, just as you need to collect data and use it to automatize and optimize your operations in a secure manner,” Nielsen said.

Those Who Can, Must

Developing a sustainable WWTP and unlocking the potential of wastewater is not something you do overnight. It requires hard work, vast investments, and employee development. Furthermore, it can be difficult for small utilities to produce energy, as the amount of wastewater might not be enough to make a good business case. However, the benefits of at least optimizing the operations and becoming more energy-efficient are a good place to start.

“The small utilities can save energy through process optimization, by becoming better at controlling biological processes, and perhaps chemical processes as well. However, utilities with a capacity of more than 200,000 PE [population equivalent] should start producing energy. The technology to do so is out there; now we just need to make it happen,” Homann advised.

About The Authors

Frederikke Rørvang Mikkelsen is the PR and communications advisor of the Energy and Environment Team at the Trade Council of Denmark in North America. Based in Houston, she primarily supports the activities of the Danish public-private partnership — the Water Technology Alliance (WTA) — which aims to share Danish know-how and foster collaboration. Prior to joining the Trade Council, Frederikke worked as a communications assistant at the Danish Society of Natural Conservation.

Frederikke Rørvang Mikkelsen is the PR and communications advisor of the Energy and Environment Team at the Trade Council of Denmark in North America. Based in Houston, she primarily supports the activities of the Danish public-private partnership — the Water Technology Alliance (WTA) — which aims to share Danish know-how and foster collaboration. Prior to joining the Trade Council, Frederikke worked as a communications assistant at the Danish Society of Natural Conservation.

Jens Enevoldsen is a senior technical advisor of the Danish Water Technology Alliance. For the past 20 years, Jens has been engaged as a manager in optimizing resource utilization for operating companies, primarily wastewater utilities. Due to a constant level of regulation from the secretariat of public utility (-2 percent/year on both OPEX and CAPEX), Jens has developed a solid understanding of optimization and utilization of a utility’s present status by increasing automation and improving data accessibility.

Jens Enevoldsen is a senior technical advisor of the Danish Water Technology Alliance. For the past 20 years, Jens has been engaged as a manager in optimizing resource utilization for operating companies, primarily wastewater utilities. Due to a constant level of regulation from the secretariat of public utility (-2 percent/year on both OPEX and CAPEX), Jens has developed a solid understanding of optimization and utilization of a utility’s present status by increasing automation and improving data accessibility.