Using UVC LEDs To Develop Cost-Effective, Measurement-Specific Water Quality Sensors

By James Peterson, product manager, Crystal IS

Rapid industrialization and tightened water quality standards are leading to an increase in global spending on water quality monitoring instrumentation. Spending in this area is projected to grow from $2.5 billion in 2014 to $3.6 billion by 2020, with some 25 percent spent on new, less expensive water quality monitoring sensors that deliver on-the-spot measurements.

Due to their low cost of ownership, low power consumption, and smaller footprint, UVC LEDs are ideally suited for many of these monitoring applications. These sensors allow water quality practitioners across a range of industries to bypass expensive and often time-consuming grab sample lab testing and obtain real-time data, often in remote field locations. In many cases, UVC LEDs enable design engineers to reduce sensor costs by 40 to 80 percent. Today’s industry-leading UVC LEDs also offer triple the lifetime at full power and in some use cases can offer an extended lifetime of up to 10 years. This enables the deployment of UVC LED water quality monitoring throughout complete processes and environments, not just at critical points, to capture real-time data across the entire water network.

Trends In Water Quality Testing

There is growing demand from industrial customers for an increase in the frequency and density of water quality testing to capture more data more points within a system. Several factors are contributing to changes in how water quality data is collected.

In developing nations, industrialization is leading to rapid changes in infrastructure and populations, and the result is an increase in the amount of effluent produced. In some developing countries, as much as 70 percent of wastewater is discharged without treatment. As a result, regulators are adopting new water quality monitoring programs to enforce a range of new compliance standards. For example, in 2015, India’s Central Pollution Control Board (CPCB) mandated real-time wastewater monitoring at tens of thousands of industrial facilities to enforce the country’s clean water standards. The CPCB and related initiatives are expected to double water and wastewater monitoring equipment spending in India by 2020.

In developed nations, stricter regulatory requirements are being enforced in specific industries such as pharmaceuticals, food and beverage, manufacturing, and industrial processing. Traces of pharmaceuticals, nitrates, heavy metals, and a constantly evolving list of new pollutants are continually entering the spotlight. Regulatory bodies are growing more concerned about these pollutants produced in their industries being dumped into municipal and environmental systems. As a result, they are demanding finer granularity and accuracy in testing locations at, or even inside, individual facilities. FDA recommendations have now progressed to the point where they recommend that every water point of use in a pharmaceutical facility be tested at least weekly, and at least one point daily.

Overall water treatment costs are also increasing, and many organizations are finding better ways to manage the effluent that they produce at an industrial level on site. This is leading to a growing demand from private industry for more discrete sensing to monitor internal treatment systems and/or manage rates. In the public sphere, high-level pollution events such as lead in Flint, MI, and PFOA contamination in Hoosick Falls, NY, as well as new micropollutants, have created water quality monitoring demands at higher frequency, specificity, and accuracy.

The Demand For More Efficient Data Generation

As these industrialization, regulatory requirements, and increasing costs place new pressure on organizations to test and monitor water quality more frequently, they are finding that their current methods are insufficient and expensive. For example, India’s CPCB has mandated 15-minute interval monitoring of chemical oxygen demand (COD) and biological oxygen demand (BOD) for industrial producers. This is virtually impossible using COD test kits because not only does the test take much longer than 15 minutes, but this would result in more than 35,000 tests each year.

Water quality practitioners typically rely on this grab sampling approach and laboratory-based instruments for analysis. Since the sample must be stored, transported, and queued at a laboratory facility, the process is slow and expensive. It is also not scalable or effective in pinpointing sources or events, and on-line sensors using ion specific electrodes are not accurate enough to meet requirements. After the sample is analyzed, it can then take hours or days to analyze, decide on, and execute changes in a process.

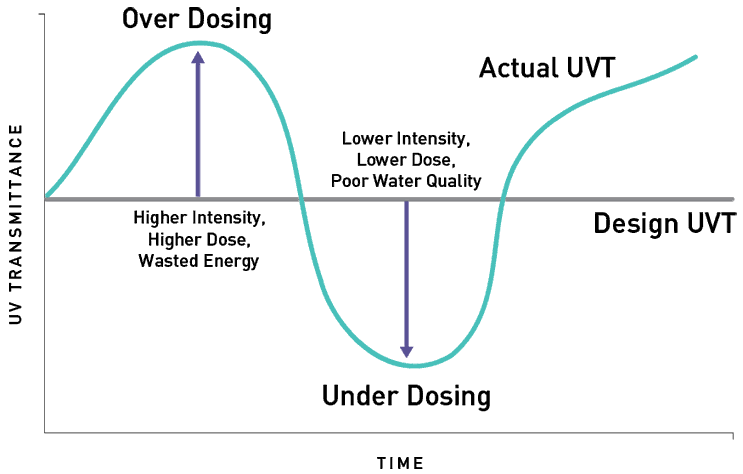

The benefit of data efficiency can extend beyond meeting regulatory requirements. For example, some municipal water companies use UV light-based disinfection systems to deactivate bacteria, viruses, and other microorganisms found in source water. These systems operate on an assumed “UV transmittance” (UVT) or the percentage of UV light that can pass through the water (70 percent, 75 percent, etc.). Changes in source water composition or unplanned changes in upstream treatment processes can affect the source water’s UVT. While a UV system disinfection dose that’s higher than necessary will result in safe water, the amount and cost of the energy the system consumes will be unnecessarily high. If the UV dose is too low, the system will not deliver enough UV light to meet plant disinfection targets.

Effect of changes in UVT of water on energy consumption and UV dose

Monitoring the UVT in real time, therefore, allows water treatment plants to fine tune the UV dosage to maintain the proper level of disinfection. Traditional UV transmittance monitors use mercury lamps. Since the lamps require time to warm up, they’re usually left on — even when the monitor isn’t in use — resulting in frequent lamp replacements and, subsequently, increased lamp-related maintenance costs. To circumvent these issues with grab sampling and lamp monitoring, some organizations have turned to analyzing surrogate parameters such as the real-time measuring of pH, temperature, conductivity, and oxygen, but these parameters must be extrapolated and only reveal very limited information about a system.

Real-Time Monitoring With UVC LEDs

Sensors and instruments that incorporate UVC LEDs have emerged as a way for industries and organizations to enhance their water quality monitoring. UVC LEDs can be deployed across water quality monitoring processes and environments to capture real-time information not only at critical points, but throughout the entire network to track total organic carbon (TOC), BOD, COD, proteins, and cleaning validation. High-performance UVC LEDs also offer high spectral quality, which enables linearity of measurement over four orders of magnitude.

UVC LEDs are compact (measuring less than 10 mm), durable, and portable, making them ideal for simplifying instruments. Their low energy requirements also make them suitable for battery operation in handheld instruments. In addition to handheld instruments, the small size of UVC LED-based instruments allows them to easily be installed across multiple water treatment environments, including directly in a pipe or open channel.

As a semiconductor device, UVC LEDs are capable of being cycled on and off thousands of times at any desired interval from instantaneous to constantly on. Because they reach full power instantly and turn on and off quickly, UVC LEDS have a service life five to 10 times longer than mercury lamp-based instruments.

The benefits that UVC LEDs bring to water quality monitoring are enabling instrument and sensor manufacturers to explore new markets and opportunities, as well as strengthen relationships with existing customers looking for faster, system-wide water quality monitoring. With high-performance UVC LEDs, design engineers can reduce costs while developing small, yet powerful, instruments tailored to specific water quality measurement applications. This enables the use of water quality not only in large industrial systems, but also in smaller-scale water systems in a variety of industries.