Using Biotechnology To Restore Productivity Of Anaerobic Digesters

By Dave Shackleton

When the production line of anaerobic digestion is slowed, efficiency is lost, and the reverse is true when holdups are cleared.

The Problem

In wastewater treatment, it is anaerobic digestion that treats the majority of the organic load in the form of sludge that is removed in primary settlement tanks or as waste activated sludge from aerobic treatment tanks.

Anaerobic digestion breaks down long-chain biochemical polymers (proteins, lipids, carbohydrates, etc.). This is done by enzymes (produced by bacteria) that break specific chemical bonds in a sequential “production line” manner.

The first step in the production line is hydrolysis, and this breaks up:

- Carbohydrates into sugars

- Proteins into amino acids

- Lipids into fatty acids

(Note that acids are produced, which will lower pH below neutral 7.)

The next step in the process is acidogenesis (the generation of more acids), as the sugars, amino acids, and fatty acids are broken down to produce substances such as acetic acid.

The final step is methanogenesis, or methane (biogas) production. The problem is that the microbes responsible for methanogenesis are very sensitive to pH and require a pH between 6.5 and 8.0 to function.

So when acidogenesis causes pH to drop below 6.5, this inhibits the methanogenesis process. This means that the process can become self-limiting over time if the pH of the digester remains low. The production line is blocked, and we say that the digester has “gone sour.”

When undigested sludge accumulates near the surface and gas bubbles are generated from below, they are trapped in this surface sludge. The effect is much like the rising of bread, where gas produced by yeast creates cavities in the dough. The sludge expands and dries out as these bubbles become entrapped. Over time, digesters can become blocked with solid sludge “crusts” that are several feet thick.

The net effect is that the volume of solids that must be treated and disposed of increases along with the costs of doing so.

The Solution

If we study the biochemical processes at play a little more closely, each step along the production line is driven by enzymes that are produced by bacteria. When pH rises and the bacteria responsible for producing the enzymes for the next step of the process are inhibited and die off, a backup is created and the whole of the rest of the production line is affected.

Adding more bacteria or microbes into such an environment is ineffective because they soon succumb to the hostile environment. However, adding the enzymes that the bacteria produce allows the process to be driven forward, and efficient digestion to be restored.

Key Parameters

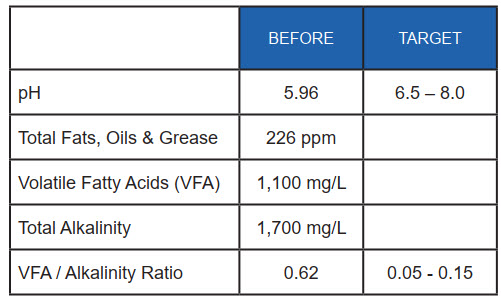

The key parameters that illustrate this problem are:

- pH, which should be above 6.5

- Total fats, oils, and grease

- Volatile fatty acids

- Total alkalinity

- Volatile fatty acids to alkalinity ratio, which should be maintained between 0.5 and 0.15.

Proof Of Performance

Two anaerobic digesters had become completely dysfunctional. The digesters themselves had a solid layer of sludge 5 feet thick, and sludge management processes were unable to cope with the volume of solids, while the costs of trying to do so were unaffordable.

Laboratory analysis of samples taken from the digesters showed how bad the situation was.

Biotechnology allows us to tackle the problem at the biochemical level directly by dosing the enzymes that are in short supply due to the inhibition of the microbes responsible for producing them, a result of low pH causing an acidic environment. These enzymes clear the holdup in the “production line” and restore functionality.

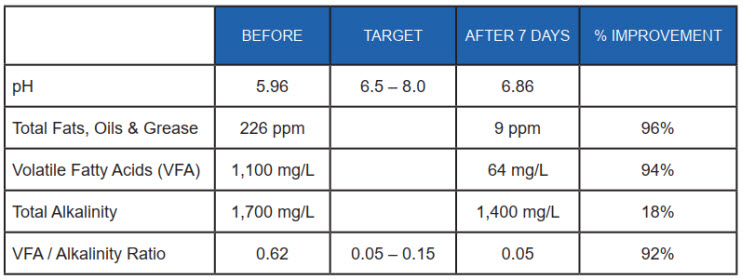

Enzymes were dosed into the digesters and circulation pumps were run for a few hours daily. The improvements achieved within seven days are shown below.

With full functionality and performance restored to the anaerobic digesters, the amount of residual sludge and solids was reduced by over 80%, making management of this easier and cheaper.

Applications

Dysfunctional anaerobic digestion is not only a problem in municipal wastewater treatment. Livestock operations make extensive use of lagoon systems for manure treatment, and these suffer from the same problems.

An anaerobic lagoon at a pig farm that has an extensive solid sludge layer on the top.

Enzyme treatment cleared this.

In one case, a bottom-based system to intermittently stir and mix the lagoon, together with enzyme treatment, ensured that not only was the performance of the lagoon optimized, but also that the accumulated sludge sediment that had reduced the effective volume of the lagoon by about 50% was digested and full volume restored.

About The Author

Dave Shackleton (daves@sis.bio) is the cofounder and CEO of SIS. BIO (www.sis.bio), a provider of biotechnology solutions to support the renewal of our world’s water systems. For the last 10 years, Dave has worked with water resource managers and wastewater systems operators across four continents to help restore compromised waterways and wastewater systems. SIS.BIO’s multidisciplinary approach prioritizes nature and eliminates the need for chemicals.

Dave Shackleton (daves@sis.bio) is the cofounder and CEO of SIS. BIO (www.sis.bio), a provider of biotechnology solutions to support the renewal of our world’s water systems. For the last 10 years, Dave has worked with water resource managers and wastewater systems operators across four continents to help restore compromised waterways and wastewater systems. SIS.BIO’s multidisciplinary approach prioritizes nature and eliminates the need for chemicals.