The Top 5 Reasons To Consider An Active Water Tank Mixer

Source: Kasco Marine

By Lucy Allen

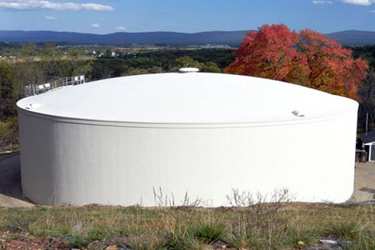

Active tank mixing increases tank longevity and improves water quality. Municipal water tanks and reservoirs are valuable assets for healthy, thriving communities. They represent a sizable capital investment and are a critical component to the quality of your potable water supply. Ensuring clean drinking water is important to the overall health and safety of your community. Here are the top five reasons to consider an active water tank mixer.

access the Article!

Log In

Get unlimited access to:

Trend and Thought Leadership Articles

Case Studies & White Papers

Extensive Product Database

Members-Only Premium Content

Welcome Back! Please Log In to Continue.

X

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.

Subscribe to Water Online

X

Subscribe to Water Online