The Rights And Wrongs Of Measuring Flow In Wastewater

Innovation is upon us in flow meter design, allowing for more technology options and better precision. Don’t let faulty installations or O&M set you back.

Flow is fundamental to the wastewater industry; the amount that flows through the various wastewater systems in the U.S. and Europe on a daily basis is roughly 100 billion gallons per day. In order to manage it (to paraphrase an old adage), it is necessary to measure it. This is where things tend to fall apart. In short, there are a lot of mistakes made when measuring flow. Generally, the mistakes that are made are “no-brainers” that can be surmounted with proper thought, or if the “cheapest” path isn’t taken.

The Mistakes We Make … And Their Implications

The mismeasurement of flow has serious implications in terms of the operation of wastewater systems and, if believed, the design as well. It can affect consenting and the assessment of the impact on the environment. So where do we really get things wrong?

The quick answer can be everywhere from the design of flow measurement structures, choosing the wrong technology or the wrong place, to poor operation; or, in some cases, accidental (through poor knowledge) or deliberate tampering to misguidedly make the treatment works “pass.”

To start at the beginning, the first place we get things wrong is not thinking about what instrumentation, including flow meters, are going to be used when designing a wastewater treatment works, as well as what needs to be managed. From this point, it’s a case of selecting the right technology for the right measurement purpose.

Let’s take some examples. The first (Figures 1 and 2) is a treatment works with a new inlet installation. It shows an inlet structure that’s inaccessible for operational staff to maintain, and also a primary structure that has been installed backwards.

This is the sort of mistake that can happen in engineering design, and although it can be corrected, the problem is so obvious that it can’t be argued. For new works, it is bad engineering design, or possibly a mistake during construction.

When you are retrofitting flow measurement instrumentation, the temptation is to simply make it fit, which is another situation where problems can prevail. The second example (Figure 3) is a situation where a flow meter has been “forced” to fit in — a poor installation resulting from poor communication with the flow meter manufacturer.

The electromagnetic flow meters have been placed downstream of 45-degree bends and upstream of non-return valves, gate valves, and other bends (flow is right to left) for sludge measurement. To minimize pipe lengths, the flow meters that control the chemicals being dosed to the sludge aren’t given a chance to measure correctly, which potentially causes more chemical to be used than needed. Simple advice from the manufacturer, which is usually available as part of product support, would have prevented this situation entirely.

The electromagnetic flow meters have been placed downstream of 45-degree bends and upstream of non-return valves, gate valves, and other bends (flow is right to left) for sludge measurement. To minimize pipe lengths, the flow meters that control the chemicals being dosed to the sludge aren’t given a chance to measure correctly, which potentially causes more chemical to be used than needed. Simple advice from the manufacturer, which is usually available as part of product support, would have prevented this situation entirely.

Lastly, in terms of design and engineering problems, is the selection of inappropriate flow meter technology. This is certainly a more subtle problem, and often engineers have to rely on  suppliers to give them best possible advice at a particular time. The “golden rule” in this regard is to think of how a flow meter is going to be operated, how it’s going to be maintained, whether it’s accessible, and whether the conditions are correct for the flow meter to operate. Figure 4 shows the inappropriate use of an ultrasonic flow meter for the size of the chamber and the flow rate that’s passing through the chamber. Due to the chamber size and flow rate, the level of water is exceeding the capacity of the weir plate, which invalidates the results of the flow meter.

suppliers to give them best possible advice at a particular time. The “golden rule” in this regard is to think of how a flow meter is going to be operated, how it’s going to be maintained, whether it’s accessible, and whether the conditions are correct for the flow meter to operate. Figure 4 shows the inappropriate use of an ultrasonic flow meter for the size of the chamber and the flow rate that’s passing through the chamber. Due to the chamber size and flow rate, the level of water is exceeding the capacity of the weir plate, which invalidates the results of the flow meter.

Getting It Right

The problems that are typically encountered with flow measurement don’t always come down to the way the flow meters are designed or installed; the culprit is more commonly the lack of basic operation and maintenance of the flow meter installation. The three main causes are:

- Lack of meter cleaning. This is prevalent with all types of flow meters and can be a major problem.

- Accidental or deliberate tampering with flow meter programming, particularly with level-based flow meters. This can have a serious effect on the flow meter reading

- Poor scaling on telemetry that can be caused by raising the maximum flow rate on-site and at the meter, but not in the telemetry system. As a result, the flow meter is incorrect by a variable factor.

Cleaning of primary structures for level-based flow meters or the flow tubes of electromagnetic flow meters can be a significant problem within the water industry, and this should be taken into account when an installation is designed. The growth of plant life on flumes and weirs, if left unchecked, will eventually cause permanent damage to the structures. This can drastically shorten the asset life, as well as affect the recorded flows by as much as 50 percent.

Cleaning of primary structures for level-based flow meters or the flow tubes of electromagnetic flow meters can be a significant problem within the water industry, and this should be taken into account when an installation is designed. The growth of plant life on flumes and weirs, if left unchecked, will eventually cause permanent damage to the structures. This can drastically shorten the asset life, as well as affect the recorded flows by as much as 50 percent.

This risk is hidden when it comes to electromagnetic flow meters as they are a closed-piped system. Therefore, it’s not possible to see the debris that accumulates within the flow measurement tube. Figures 5 and 6 show the debris that can accumulate within an electromagnetic flow meter, which is why a regular cleaning regimen is important.

This risk is hidden when it comes to electromagnetic flow meters as they are a closed-piped system. Therefore, it’s not possible to see the debris that accumulates within the flow measurement tube. Figures 5 and 6 show the debris that can accumulate within an electromagnetic flow meter, which is why a regular cleaning regimen is important.

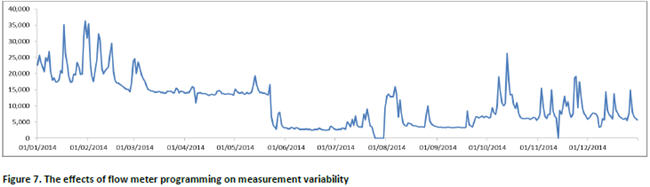

The risks of tampering or scaling errors for flow meter devices can have similar effects on the flow measurement system in that the flow meter can read significant amounts of error. Figure 7 shows where an error in the setup of the flow meter surrounding the distance from the bottom of the chamber can cause a variance of as much as 3.5 million gallons (13,000 m3) in the flow measurement readings.

In the graph it can be seen that around January 3rd the flow meter total daily volume drops dramatically. This was because the empty distance that the flow meter measures was set to the bottom of the weir plat — a rectangular weir in this case — and not the bottom of the chamber. This changed the distance that the flow meter measured by 2.5” (64 mm), which equates to 3.5 MGD (13,000 m3/day). The same effect could be seen with an incorrectly scaled flow meter.

It can be said that we learn from our mistakes, and generally we do. There are thousands of flow meters on wastewater treatment works around the world, and the vast majority are designed, installed, operated, and maintained correctly. Various flow measurement companies are constantly developing new methods of measurement, including technologies using laser, radar, and microwave to join the well tried and tested techniques of ultrasonic and electromagnetic. There are other technologies that are being refined such as mass flow and time-of-flight meters.

All of the technologies available are valid, and all of them have their strengths and their weaknesses. It’s up to the engineer to select the most appropriate technology and to ensure that it is designed and installed correctly, which can be a difficult process. Thankfully, flow meter suppliers are usually available to help get a technology working as well as it should.

The measurement of flow should be simple, as it is a fundamental part of our industry. Its importance should not be underestimated, however, as it has the potential impacts on wastewater operations and engineering can be severe — exacting a cost far greater than spending more to measure correctly at the beginning of a project.

Oliver Grievson is the wastewater flow & quality instrumentation specialist at the Foundation for Water Research, the director of the sensors for Water Interest Group, a member of the ICA Special Interest Group of the International Water Association, and founder of the LinkedIn Group “Water Industry Process Automation & Control” — all in addition to his duties as a flow compliance & regulatory efficiency manager. Working with other flow specialists, Grievson is preparing a wastewater flow manual for free release in late 2015, through the Foundation for Water Research.