SWAN Corner: Utilizing IoT Data To Revolutionize Municipal Tertiary Treatment

By John Ong

Background

The DE NORA TETRA® Modular DeepBed Filter (MDBF) Plant is an established tertiary wastewater filtration technology for the UK municipal water market to remove total suspended solids (TSS) before final effluent is discharged to a water course.

Objectives

The MDBF is equipped with an Internet of Things (IoT) device securely transmitting filter specific PLC data, which would otherwise not be available on SCADA systems, to Microsoft Azure IOT Central for remote monitoring via any browser on any internet connected device. The primary purpose of the trial was to identify opportunities for fault identification that would enable development of predictive maintenance workflows. A secondary objective was to provide a continuous stream of data to further evaluate the existing energy saving features incorporated in the MDBF process. The additional granularity would support the optimisation of existing filter backwashing sequences with the aim to reduce both the frequency, and sequence runtimes, of the air blowers and water pumps whilst ensuring compliant process treatment. Prime movers being the most significant power consumers on municipal wastewater sites.

In-Service Example

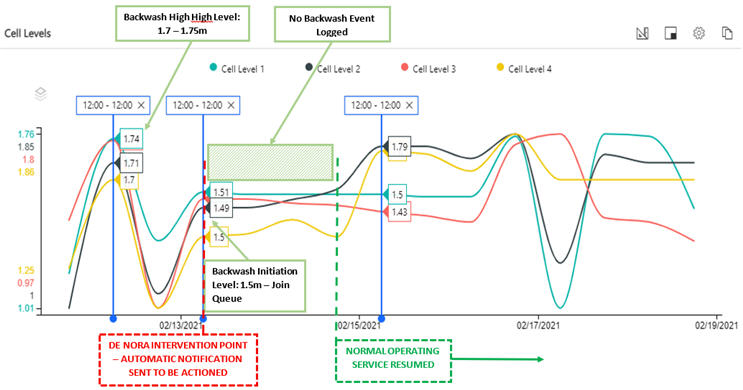

Having access to live data directly sent by 3G/4G from site for all our available PLC tags has enabled a greater level of insight. De Nora engineers were able to diagnose an issue with the filter backwashing during the recent February period. During normal operation, when the cells reach the high level setpoint of 1.5 metres a backwash is initiated or, if another cell is already in backwash, the cells are added to a backwash queue. We are able to confirm a cell has backwashed when the high level of 1.70–1.75 metres is reached. This is then usually followed by a drop in cell water level, due to the cleaner media bed, for the period following a full backwash. Figure 1 is a sample of the live data updating every 3 minutes.

Utilising our remote monitoring dashboard, on 13th February, all 4 cells had reached the high level setpoint of 1.5m as indicated. However, none of the cells had reached the high level of 1.70–1.75 metres that indicates a completed backwash. As a result, within the existing MDBF software, this operating condition would not have raised an alarm that a fault condition had been identified. However, when Remote Monitor enabled, a notification is circulated by email that an issue has been identified and operator action is required.

Figure 1: MDBF Cell Levels

In the intervening period, our engineers had all the tools they needed to problem solve with access to all current and historical PLC tags. Using our live dashboards, our engineers instantly pulled up the backwash pump duty and standby run events to analyse. The data (Figure 2) showed the pumps running as expected until 13th February where the data showed the PLC tried to initiate both the duty (P1) and standby (P2) backwash pumps. The duty runtime was noted as minimal and the system then tried to run the standby pump to no avail. A backwash pump fault was diagnosed.

Figure 2: MDBF Backwash Pump Operations

Note: In normal operation (12th February) the time difference between P1 and P2 showing the pumps are successfully alternating their use.

Due to the cold weather our engineers immediately attributed the data to frozen pumps. Although the pumps were thermally lagged, it proved insufficient to maintain performance during recent cold weather. The positive for the water company was that they were able to allocate resource upon the early notification and, when resource arrived on site, they were able to go straight to the root cause, arriving prepared with suitable equipment, to immediately rectify and return the plant to normal service.

Maximising Data For Preventative Action

Now our DE NORA TETRA MDBF plants are Remote Monitor capable, it enables our engineers to remotely interrogate filter performance in ways not previously possible. We are now able to see events that allow us to identify and, most importantly, action issues faster to reduce, or even eliminate, process downtime that result in periods where tertiary treatment is bypassed or filter performance is compromised. All having a positive effect on water quality discharged to our rivers and reducing the impact on all upstream processes.

IoT has enabled De Nora to reimagine how our DE NORA TETRA Modular DeepBed Filter (MDBF) Plant performs in the field. The findings here have now led to further software optimisations, related to identified events which we previously had no visibility, that make the tertiary treatment process technology perform smarter in a wider range of operating conditions. The findings have led to future enhancements, including new process metrics that enables the utilities to have a deeper understanding of their filtration asset’s health and status. The outcomes here are also an early-stage enabler for building in machine learning, for smarter automated plant operation under a wider range of operating conditions, to optimize power consumption of the plant.

The benefits are particularly applicable to remote sites, where access, especially during winter weather periods is often challenging. Resourcing of site operations teams has now been re-evaluated by many utilities across the world due to COVID-19 and the advancement of early fault identification and predictive maintenance using a remote solution offers a significant benefit to resource planners as the world moves away from dedicated site operations teams, to a leaner model, whilst still requiring full status and visibility of plant health. Notifications are easily tailored to extend to the appropriate personnel depending on severity level, critical path, and data sensitivity. Resource entering an area can have instant alerts and warnings, via their network connected device, to safely expedite completion of the task.

John Ong is the Projects and Engineering Manager for De Nora Water Technologies UK.

SWAN, the Smart Water Networks Forum (SWAN), is the leading global hub for the smart water sector. A UK-based non-profit, SWAN brings together leading international water utilities, solution providers, academics, investors, regulators, and other industry experts to accelerate the awareness and adoption of “smart,” data-driven solutions in water and wastewater networks worldwide. Learn more at www.swan-forum.com.