SWAN Corner: Digital Twin At A 45-Year-Old Wastewater Treatment Plant

By Igor Starkov

The multi-award-winning Pukete Wastewater Treatment Plant digital twin project takes the complex and very relevant problem of collecting, integrating, and maintaining information about existing asset stock. It breaks this problem down into smaller, palatable chunks and addresses each component of the problem though the implementation of several technologies. This is underpinned by trust and true collaboration between Beca (the consulting team), EcoDomus (software vendor), and Hamilton City Council (the client).

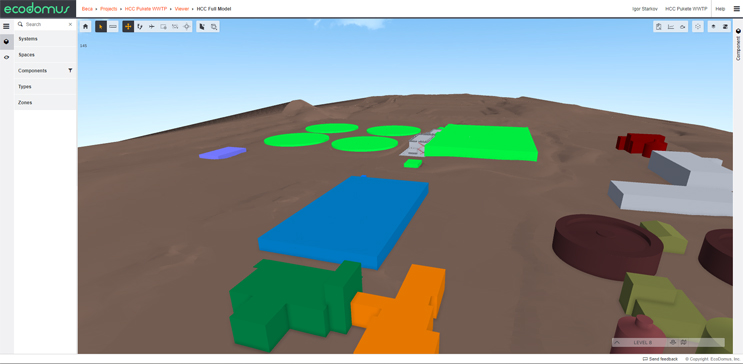

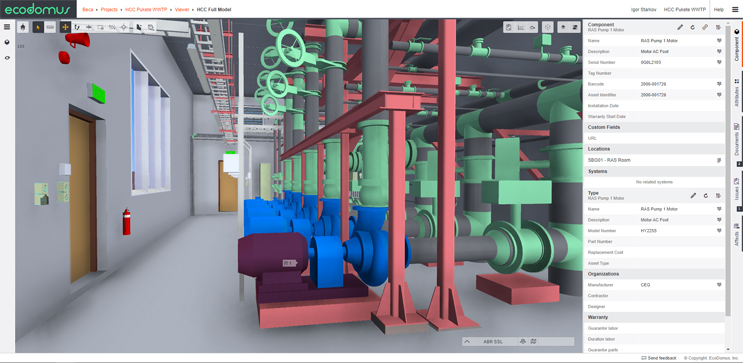

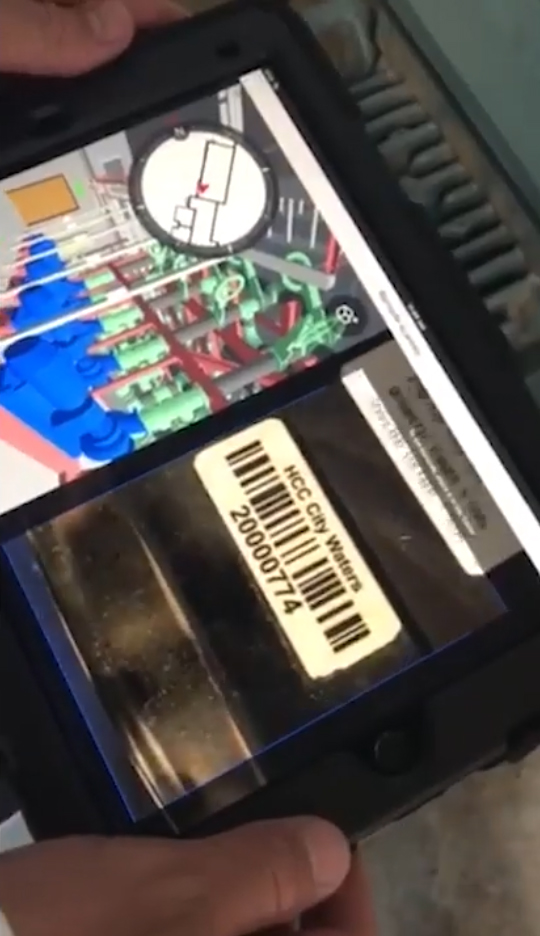

Hamilton City Council’s challenge centered on the accessibility, reliability, and completeness of asset information and as-built records. The solution proposed involved implementing several technologies that were appropriate to each component of the challenge. This included the use of unmanned aerial vehicles (UAV) to capture site-wide geometry (see Figure 1 and resulting Figure 2), laser scanners to capture building and asset geometry, 3D modelling tools to develop building information models, and a web-based integration tool (EcoDomus CDE, see Figure 3) to create the asset information model and mobile devices to link the digital assets to barcodes (see Figure 4) on their physical asset counterparts. Now, contractors onsite have the opportunity to use a barcode scanning app on their tablets to confirm they’re working on the correct piece of equipment.

Figure 2

At the broadest level, this project provides the functionality to visualise and interrogate more detailed, centralised information about the assets.

Managing contractors will soon be recast as an exact science, with the 3D model confirming the identity of equipment, its location, and important asset data — before works commence. The model also serves as a tool to run contractor safety inductions.

“To say that we’ve got these assets, with these attributes, and all the information is linked to the correct asset onsite, is great — it removes confusion,” said Parvati Patel, Asset Engineer, Hamilton City Council. “Aggregating this kind of information in a visual format makes it easy to access and cross reference — and much simpler for people to find what they need when performing asset management and maintenance activities.”

Hamilton is New Zealand’s fourth largest city and one of its fastest growing. With more than 20,000 people expected to call Hamilton home in the next 10 years and with significant new growth areas being developed, demands on water resources are only set to grow. The Council engaged Beca to undertake a pilot project to help it collect and manage asset data for their only wastewater treatment plant at Pukete.

Figure 3

Hamilton City Council supports the concept of digital twins. The benefit they provide in terms of assisting decision-making is recognised, however the client notes the following:

- Clarity is sought on the intended purpose of this option and consideration on what would be a reasonable timeframe for implementation of digital twin information technology.

- The term ‘digital twin’ is still new to the industry. A definition should be created to ensure a minimum standard of what makes a ‘digital twin’.

- A minimum standard of data should be set to ensure greater levels of efficiency and consistency between infrastructure providers and industry members (and as a result, greater outcomes).

All three issues raised by HCC were focus areas of SWAN’s efforts over the past year.

Figure 4

Beca developed a sophisticated 3D digital model of the existing facility that brought together existing information about the asset with newly captured data. The BIM model was developed with costs in mind, which helped put boundaries to the scope of its development. “Costs associated with developing the model should be proportionate to client needs,” explains Glenn Jowett, senior associate and BIM delivery lead at Beca. “You’ve got to understand why you’re developing something and what it will be used for. Why document every nut and bolt in steelwork when all you need to know is what’s there and its position?”

Migrating the model to EcoDomus, a cloud-based building lifecycle management platform, set the scene for the addition of data, with key asset data fields attributed to elements within the model. Operation and maintenance (O&M) information, including process and instrumentation diagrams, process flow diagrams, operations manuals and warranties, were attached to the model, centralising asset information to create a “single source of truth” for operation and maintenance activities.

After the model is enhanced by adding O&M data many clients establish an integrated “system of systems”, which is in our opinion a true definition of “digital twin” — a combination of all data sources and technologies supporting facility life cycle. A “digital twin” includes BIM, GIS, ERP, CMMS, IoT, SCADA, CCTV, and other systems that allow comparing how the facility is supposed to operate and how it actually operates, providing valuable insights about areas of concern, and in the future automatically adjusting parameters of working equipment based on the key performance indicators (KPIs) set up by the facility owner.

Igor Starkov is the CEO of EcoDomus, an information technology firm focusing on improving the ways buildings are designed, built, managed, and retrofitted using building information modeling (BIM).

SWAN, the Smart Water Networks Forum (SWAN), is the leading global hub for the smart water sector. A UK-based non-profit, SWAN brings together leading international water utilities, solution providers, academics, investors, regulators, and other industry experts to accelerate the awareness and adoption of “smart,” data-driven solutions in water and wastewater networks worldwide. Learn more at www.swan-forum.com