SWAN Corner: At the Heart Of Water Infrastructure — Unlocking The Hidden Value By Redrawing Pump Characteristic Curves Under Real Operating Conditions

By Anastasia A. Papadopoulou

Urban water utilities are increasingly burdened by high energy demands, with pumping stations accounting for over 50% of total operational expenditures. This elevated cost is primarily driven by factors such as system topography, required hydraulic head, suboptimal pump sizing, and inefficient operational strategies. It is a fact that globally, water distribution systems consume approximately 1 kWh per cubic meter of water delivered, translating to an average annual per capita consumption of 100 kWh (Lam et al., 2017). In the U.S. alone, the water sector is responsible for around 4% of national electricity usage (Salomons et al., 2010). Over time, pump performance deteriorates due to mechanical wear, changes in system dynamics, and fouling. Longitudinal studies indicate that hydraulic head losses may reach 1% after just two years of operation and up to 10% after nine years (Eaton et al., 2018). These inefficiencies emphasize the necessity for continuous condition monitoring and performance assessment of pumping assets to ensure both operational reliability and energy efficiency. However, traditional field-based performance evaluations are often labor-intensive, cost-prohibitive, and technically challenging to implement at scale.

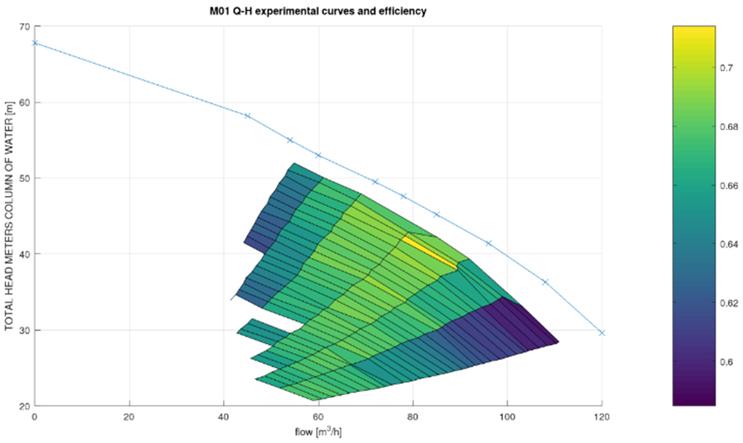

To address these limitations, a novel, data-driven optimization framework was developed, supported by a scalable IoT-based tool tailored for water utilities. This system integrates advanced telemetry, remote sensing, and supervisory control technologies, enabling real-time pump monitoring, intelligent control, and proactive energy management. The core innovation lies in the paradigm shift from the conventional Best Efficiency Point (BEP) — which optimizes pumps based solely on hydraulic efficiency — to a more comprehensive metric termed the Best Electricity Use Point (BEUP). BEUP represents the operational point at which total energy consumption is minimized, taking into account the entire system’s dynamic performance, including electrical, mechanical, and hydraulic subsystems. The proposed methodology involves real-time estimation and continuous updating of three critical pump performance curves under actual field conditions: the Q–H Curve (flow vs. hydraulic head) which represents system resistance and pump delivery capacity; the Q–η Curve (flow vs. efficiency) which captures variations in pump efficiency across different operating points and the Q–P Curve (flow vs. axial power) which links flow rate to actual energy input, reflecting true electrical demand.

By dynamically analyzing these curves, the methodology identifies suboptimal operating points and recommends or automatically applies control strategies to minimize energy use while maintaining service levels. This approach enables utilities to achieve substantial energy savings, reduce greenhouse gas emissions, extend pump lifespan, and enhance the overall sustainability and resilience of water distribution networks.

To develop a Scalable Smart Water Framework aimed at optimizing energy efficiency in pumping operations, a structured, multi-phase implementation strategy was adopted, consisting of the following key stages:

- 1st Step – Data Acquisition and Performance Baseline Analysis

The initial phase involved the systematic collection of high-resolution operational data from existing pump stations through supervisory control and data acquisition (SCADA) systems and variable frequency drives (VFDs). Key performance parameters continuously monitored included volumetric flow rate (Q), hydraulic head (H), pump shaft rotational speed (ν), electrical power input (P) and water level in storage tanks (h). This real-time telemetry provided a comprehensive baseline dataset, enabling the characterization of current pump performance under varying hydraulic and operational conditions.

- 2nd Step – Experimental Characterization via Stepwise Regression Protocol

A stepwise regression methodology was used to establish the pump’s characteristic curves at varying rotational speeds. The procedure begins with the butterfly valve (BFV) in a fully open position, followed by its incremental closure in 15 uniform steps to systematically reduce the flow rate (Q). Key parameters, including flow rate (Q), hydraulic head (H), pump rotational speed (ν), power consumption (P), and tank level (h), are monitored and recorded via SCADA. This protocol enabled the identification of optimal rotational speed ranges corresponding to minimum power consumption, laying the foundation for BEUP-based operational strategies.

- 3rd Step – Real-Time Optimization and Adaptive Control

The integration of the experimental results into a cloud-based IoT platform facilitated the real-time monitoring and intelligent control of pump operations. The system continuously assessed real-time demand conditions and hydraulic feedback, adjusted the rotational speed (ν) of each pump dynamically to maintain operation within the BEUP envelope and ensured optimal performance across varying diurnal and seasonal demand profiles, minimizing specific energy consumption (kWh/m³) and enhancing operational resilience.

- 4th Step – Pilot Deployment and Validation in a High-Demand Environment

The framework was field-tested at the Municipal Water Utility of Kos Island, Greece—an area located in the South Aegean Region characterized by a high seasonal population influx due to tourism. During the summer months, water demand and operational costs nearly double, making energy-efficient operation imperative. This pilot served as a stress test for the framework, validating its ability to dynamically adapt to extreme fluctuations in demand while maintaining energy efficiency.

The entire methodology and testing protocol were developed in close collaboration with the Hydraulics and Hydraulic Works Laboratory of the Department of Civil Engineering at the Aristotle University of Thessaloniki, under the scientific supervision of Professor V. Kanakoudis.

A critical inflection point in the process emerged during the initial optimization phase, when efforts guided by the BEP paradigm failed to yield the anticipated reductions in energy consumption. The BEP is traditionally defined as the operating point at which a pump achieves maximum hydraulic efficiency, based on idealized laboratory conditions and assuming stable system parameters. While it remains a cornerstone in pump selection and design, our field-deployed instrumentation and telemetry data revealed a substantial divergence between BEP-based operation and actual energy performance under real-world conditions. Specifically, despite pumps operating at or near their manufacturer-specified BEP, measured electrical power consumption remained disproportionately high, suggesting that hydraulic efficiency alone is an incomplete metric for optimizing total energy use in dynamic, field-based water distribution systems.

This realization necessitated a paradigm shift in our methodological approach. In response, the research team introduced a new operational metric termed the BEUP — a field-calibrated point of operation that prioritizes minimization of total energy input (kWh/m³) rather than solely maximizing hydraulic efficiency. BEUP integrates both the hydraulic performance of the pump and the electromechanical efficiency of the drive system, explicitly accounting for non-ideal and time-varying conditions such as fluctuating demand profiles, transient flow and head requirements, system aging and degradation (e.g., wear, corrosion, scaling), and electrical motor and VFD inefficiencies

The experimental analysis confirmed that operation at the BEUP, as opposed to the traditional BEP, can result in energy savings of 15% to 20%, contingent upon the specific hydraulic configuration, pump type, and demand variability of the system. These savings were consistently validated across multiple controlled testing cycles and accurately measured using power analyzers integrated into the SCADA system, ensuring high-resolution data acquisition and reliability.

The successful field deployment of the BEUP framework in the municipal water utility of Kos Island, Greece, marked a turning point in stakeholder engagement. Moreover, the case of Kos Island — characterized by sharp seasonal fluctuations in population due to tourism — highlighted the resilience and adaptability of the BEUP-based optimization approach under highly variable demand conditions. In such regions, where water consumption and pumping load may double during peak months, the capacity to dynamically adjust pump operations in real time proved to be crucial for maintaining energy efficiency and service reliability.

The successful implementation of the BEUP methodology has influenced the broader strategic direction of the research, supporting the development of a replicable, modular framework for energy-efficient water management. Its applicability across diverse geographical and operational contexts — including aging infrastructure and heterogeneous pump configurations — demonstrates its potential for wide-scale adoption by water utilities seeking to reduce energy costs and carbon emissions.

Anastasia A. Papadopoulou, is a Senior Researcher in Water Supply Systems at Ianic, a member of the Olympios Group in Greece. She is a mechanical engineer and innovation advocate with a strong focus on sustainable water management. Her work and studies in University of Thessaly bridge the gap between academic research and real-world implementation, specializing in the integration of IoT, energy optimization, and policy development in municipal water utilities. Anastasia’s research spans the energy-water nexus, with a particular emphasis on pumping systems. Her work promotes equitable cost allocation, vulnerability assessment, and resilience planning, aligning closely with EU Green Deal objectives and global climate targets.

Anastasia A. Papadopoulou, is a Senior Researcher in Water Supply Systems at Ianic, a member of the Olympios Group in Greece. She is a mechanical engineer and innovation advocate with a strong focus on sustainable water management. Her work and studies in University of Thessaly bridge the gap between academic research and real-world implementation, specializing in the integration of IoT, energy optimization, and policy development in municipal water utilities. Anastasia’s research spans the energy-water nexus, with a particular emphasis on pumping systems. Her work promotes equitable cost allocation, vulnerability assessment, and resilience planning, aligning closely with EU Green Deal objectives and global climate targets.

SWAN, the Smart Water Networks Forum (SWAN), is the leading global hub for the smart water sector. A UK-based non-profit, SWAN brings together leading international water utilities, solution providers, academics, investors, regulators, and other industry experts to accelerate the awareness and adoption of “smart,” data-driven solutions in water and wastewater networks worldwide. Learn more at www.swan-forum.com.