Super-Charged Wastewater Treatment And Energy Production

By Kevin Westerling,

@KevinOnWater

“Bioelectrochemistry” is a mouthful, but it’s a word you should get familiar with if your goal is sustainable, energy-efficient industrial wastewater treatment.

It describes the electrochemical conversion of energy initiated by microbes with a very particular set of skills [nod to Liam Neeson fans] — the ability to generate and consume electricity while treating and sensing pollutants in wastewater.

A number of companies have tried to commercialize this phenomenon since its discovery in 1999, but Cambrian Innovation seems to have emerged as the front-runner. Cambrian has earned numerous awards and plaudits — recent examples include ‘2015 World Economic Forum Technology Pioneer’ and ‘2015 Sustainia 100 Award Winner’ — and owns the only bioelectrochemical process backed by real-world installations and results.

Cambrian’s bioelectrochemistry has a unique, patented twist. It goes by (another tongue-twister) “electromethanogenesis,” wherein biologically-coated electrodes convert organic pollutants into electricity and secondary electrodes convert electricity into methane fuel. Facilitated by Cambrian’s EcoVolt system, the process is sustainable for reasons beyond energy savings; it also enables on-site reuse, utilizes a smaller physical footprint, and can take waste-hauling trucks off the road for companies (commonly food and beverage producers) that cannot discharge to sewers with their existing treatment regime.

I spoke with Justin Buck, Cambrian Innovation’s CTO, from the Innovation Pavilion at WEFTEC 2015 to understand how this technology — deemed a breakthrough by so many industry and ‘innovation’ observers — can potentially disrupt the current marketplace. Learn the process and its benefits through the following Q&A…

Describe the functionality of the EcoVolt system. How does it work?

The system is designed to solve industrial resource challenges by harnessing the power of natural systems, closing the resource loop while generating profit for customers.

Naturally-occurring microbes catalyze reactions that treat wastewater and generate value-add byproducts. It’s the first wastewater treatment system to incorporate bioelectrochemical technology. The microbes treat high-strength wastewater and generate high-quality methane gas.

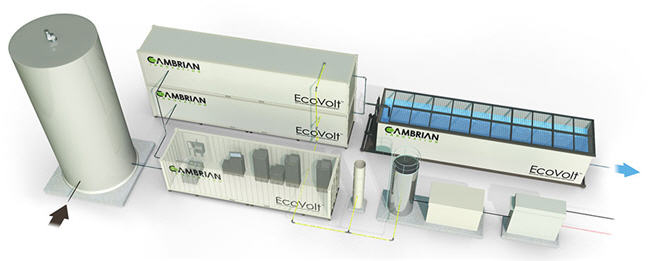

The EcoVolt Reactor can be paired with Cambrian’s membrane bioreactor (MBR) to be a highly efficient complete water treatment solution that cleans wastewater for broad onsite reuse or sewer discharge. The systems can be stacked for space efficiency, controlled remotely, and expanded as needed. This allows growing industries to scale and deploy capital only at the time of expansion.

What markets would benefit most from the technology?

The EcoVolt Reactor and EcoVolt MBR were designed specifically for industrial food and beverage producers generating wastewater with high levels of biological oxygen demand (BOD) that must be treated, usually at very high cost. In addition to having a high BOD load, food and beverage companies also require large amounts of energy and water to operate. Companies that are not in the business of water management and do not want to deploy precious capital and manpower for non-core business processes will benefit from our technology. By providing real-time and remote monitoring, clients can focus on what they do best, rather than manage the ins and outs of water treatment. This makes sustainability a real option where it may not have been viable before.

What are the main drivers for installing EcoVolt?

Breweries and wineries increasingly face soaring municipal wastewater treatment fees, while water scarcity in California and elsewhere is driving up prices for fresh water. We have seen these pressures force some of the most successful breweries to make costly decisions about how to maintain production. Lagunitas Brewing Company, for example, could not dispose their water into their local sewer, so instead they trucked wastewater to a larger, neighboring water utility. Our technology allows water-intensive industries to continue operating with a distributed wastewater treatment system that saves water, produces clean energy, and slashes costs. It’s a compelling package for industrial companies.

How mature and tested is the technology?

Cambrian Innovation’s technical team has been researching and developing bioelectrochemical technology behind Cambrian’s product line since 2006. Cambrian received funding from NASA to develop a resource recovery technology for outer space, and the DOD and EPA on self-powered water treatment for off-grid applications. We have also won technology development grants from USDA, the National Science Foundation (NSF), and others.

Justin Buck, chief technology officer, Cambrian Innovation

The technology behind EcoVolt was conceived in 2009 and rapidly developed to a pilot demonstration by 2012. After two successful pilots — the first for 15 months at Clos du Bois Winery and the second for eight months at Bear Republic Brewing Company, Cambrian launched the product offering in 2013 and delivered our first commercial systems to both Bear Republic and Lagunitas Brewery in 2014. Today, we work closely with partners to deliver systems seamlessly and on schedule.

What specific results were achieved for the existing installations?

The Lagunitas Brewery, located in drought-afflicted California, can treat 60,000 gallons of water per day with the EcoVolt Reactor. The system can generate 130 kilowatts of renewable electricity and 45,000 therms of heat per year. Now, with the addition of the EcoVolt MBR, more than 40 percent of the site’s current demand of clean water can be produced. The brewery is cutting annual carbon emissions by 1,600 metric tons, which is equivalent to planting 1,580 acres of forest every year. Another way to think about the impact is by comparing the ratio of water-to-beer with our system against the ratio with business as usual. Lagunitas is reducing their ratio from 4/1 to 2.5/1.

How do you see the technology progressing?

We partner with our clients to collaborate on design, and we’re constantly looking for new ways to advance bioelectrochemical applications — especially where the most devastating and urgent issues are being faced.

Following upon the successful launch of the EcoVolt system, Cambrian Innovation is also continuing to pursue R&D to develop new and innovative solutions to problems in the industry. We are actively pursuing advanced nutrient removal, low-energy BOD polishing, and nitrate-sensing technologies. Many of these research projects are in partnership with the DOD, NASA, and the EPA.

What are the footprint, energy-efficiency, and cost/ROI implications for the EcoVolt system vs. alternatives?

Aerobic wastewater treatment typically takes 1.5 kilowatt hour for each kilogram of BOD removed. There’s actually 3 kilowatt hours trapped in each kilogram of BOD –– why spend money on treatment compliance when you could earn a return of up to 50 percent? The EcoVolt Reactor delivers a typical ROI of approximately 25 percent. Each reactor reduces carbon emissions equivalent to planting hundreds of acres of trees. Anaerobic systems like EcoVolt are capable of achieving higher organic loading rates than aerobic treatment systems. However, EcoVolt is still more efficient — with a footprint three times smaller than other anaerobic systems.

Are there other technologies available that leverage electrically-charged microbes?

There are a couple of groups developing these technologies, but they don’t have viable products on the market yet. Cambrian Innovation enjoys exclusivity on patented electromethanogenesis technology. Cambrian’s EcoVolt Reactor is the world’s first and we’ve capitalized on that head-start to create the most energy-efficient technology around, while fitting the solution into a modular, containerized form-factor. Cambrian’s modular unit allows the technology to be deployed both at a small- and large-scale. Other technologies just aren’t as flexible. Cambrian has also been able to fine-tune a technology that can process a much wider range of BOD streams and get water cleaner at lower cost than bioelectric competitors. We also provide a remote management platform for professional support around the clock. We’re built from the ground up for energy generation. Other companies treat it more as a compliance question.

How is EcoVolt a potential ‘game-changer’?

After years of being an afterthought, matching water resources with global growth is now at the center of global priorities. Cambrian was built to meet the unique needs of this new era of water scarcity by developing cost-efficient water reuse technologies. Consider that while just a fraction of wastewater is reused today, it’s already a $3 billion market — and growing 8 percent annually. The North American market for biogas production is forecasted to reach $1.2 billion by 2016. Additionally, underinvestment in water utilities worldwide is exacerbating scarcity, and bringing wastewater systems up to date will require a projected $1 trillion investment over the next 20 years. Cambrian’s technology allows businesses to continue production and maintain growth while reducing the environmental footprint and pressures on municipalities.

Due to its technology and product architecture, the EcoVolt system could lead to the widespread adoption of energy-positive wastewater treatment and reuse in new applications. This magnitude of adoption would positively shift our water systems worldwide and benefit the environment.