5 Standout Membrane Technologies

By Kevin Westerling,

@KevinOnWater

Membrane technology, highly significant for surface water treatment, desalination, and wastewater reuse, is poised for major impact due to the dwindling availability of water. Here are five featured technologies to put on your radar.

The American Membrane Technology Association (AMTA)/American Water Works Association (AWWA) Membrane Technology Conference & Exhibition continued to establish itself as the premier membrane conference in North America with a strong showing in San Antonio, TX, Feb. 25 to 28. The conference drew approximately 1,100 attendees and 100 exhibitors to the Henry B. Gonzalez Convention Center for four days of networking and education devoted to membrane technology. The teaming of AMTA and AWWA, enjoying their second year of partnership, has worked well in that respect: AMTA brings the technology providers to the table (or booths), while AWWA’s considerable standing and influence attracts utilities and universities.

While the show is clearly gaining in momentum and size, it is just small enough that a roving editor can cover a lot of ground in a few days. Not to say I made it to all the booths, but of the many companies and products I encountered, the following five stood out as most impressive.

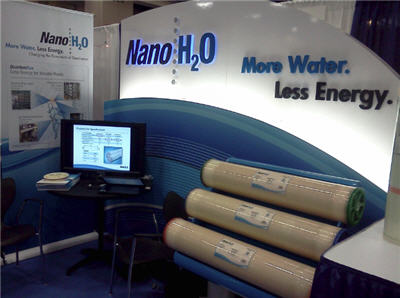

QuantumFlux by NanoH2O

Low-cost desalination has been talked about for years as a potential game-changer for the industry — for the world, really. While there are no proclamations to that extent here, NanoH2O has made its presence felt rather quickly. Having just gone to market with its QuantumFlux seawater reverse osmosis (SWRO) membranes in 2010, the company has already won numerous awards, including the 2010 Wall Street Journal Innovation Award and the 2011 Aquatech Innovation Award. In 2012, NanoH2O was also named an Artemis Project Top 50 Water Company and a Global Cleantech 100 Company.

NanoH2O — off to a bright start

The innovation drawing such attention is a thin-film nanocomposite that, according to the company, increases membrane permeability by 50% to 100% over traditional polyamide membranes, with salt rejection of at least 99.7%. When asked how these characteristics are “changing the economics of desalination,” as the company’s tagline professes, VP of Market Development Nicholas Dyner cited three possible outcomes for plants that use QuantumFlux:

- Energy reduction of up to 20%,

- An increase of production capacity up to 70% (without changing operating costs), or

- Up to 40% reduction in plant footprint.

Available in standard 4-in. and 8-in. diameter elements, the technology is being readily adopted, with installations thus far in more than 100 commercial sites and 33 countries.

Arkal Super Galaxy Self-Cleaning Disc Filter by Amiad Water Systems

Once you’ve found quality membranes, it’s wise to protect them — especially in harsh environments. Seizing on this need, Amiad created the Super Galaxy Self-Cleaning Disc Filter. The polymer construction stands up to saltwater, while the modularity of the unit allows for either vertical or horizontal installation. In high-rent coastal environments (where desalination plants are often located), this space-saving feature can translate into dollar savings.

Membranes take shelter in the Super Galaxy pod.

Each pod in the Super Galaxy is capable of handling up to 880 gallons/minute (1.26 MGD) of seawater at 100 microns — and can be scaled up to handle large jobs. One such job, I learned, is at the Ashdod Desalination Plant in Israel, which is a country at the forefront of desalination. The plant, just brought online in 2013, will use Super Galaxy filters to protect its ultrafiltration (UF) membranes and produce 100 million cubic meters of water per year.

AltaPac by WesTech

For jobs on a smaller scale, WesTech offers the AltaPac series of all-in-one, off-the-shelf skids. These standardized systems are designed for low flow rates — 10 to 300 gpm, depending on the model (three available) and the application (tertiary wastewater, surface water, or groundwater). Each skid is equipped with low-fouling PVDF (polyvinylidene fluoride) UF membranes, in addition to all the obligatory pumps, valves, and components. Marketed specifically to small communities, the systems are designed for easy installation and operation. According to Research Technology Engineer Libbie Linton, “just about anyone can set up and run it.”

Libbie Linton at the WesTech booth

The UF membranes are NSF/ANSI 61-certified, with treatment parameters including turbidity reduction to less than 0.1 NTU (nephelometric turbidity units), 99.9999% giardia and cryptosporidium removal, 1.5-log removal of viruses, and a SDI (silt density index) less than 3. With regard to footprint, each skid in the AltaPac series has a width of 4.8 ft. wide. The largest unit is 14.8 ft. long and 11 ft. tall, while the smallest is 9.8 ft. long and stands 9.5 ft. tall.

Lewabrane Membrane Separation Elements by LANXESS

Industrial water treatment often involves brackish water, but membranes used in such environments are highly susceptible to organic or biological fouling. As dissolved solids form deposits on the membrane surface — known as concentration polarization — separation capacity is diminished, maintenance is needed, and the bottom line suffers. To help resolve these issues, LANXESS developed its Lewabrane reverse osmosis (RO) membrane elements, which were introduced for the first time at this year’s show. The design features polyamide composite membranes wound in several layers to form a spiral shape, with available surface areas of 400, 370, or 90 sq. ft. The latter of those has a diameter of 4 in., while the larger types come in 8-in. elements.

The Lewabrane RO membrane element, inside and out

By generating greater turbulence in the feedwater channel, fewer solids accumulate on the membrane surface, explained Alan Sharpe of LANXESS. If realized, this reduction in fouling would mean less maintenance and higher output capacity — and a better bottom line.

AquaDisk Cloth Media by Aqua-Aerobic Systems

While Aqua-Aerobic Systems fit right in at AMTA/AWWA with its UF membrane system on display, it was the cloth media the company was showcasing that caught my eye. Not recognizing the immediate connection to membranes, I learned from Senior Application Engineer Dave Holland that cloth media filtration is a useful pretreatment option for ultrafiltration in wastewater reuse applications. In fact, he presented a paper on the subject during the last day of the conference.

AquaDisk Cloth Media resembles a rug, but acts like a vacuum.

According to Holland’s research, cloth media with a 5-micron nominal rating offered a 30% improvement in normalized permeability at a flux of 40 lmh (liters per square meter of membrane per hour) and a 45% improvement at a flux of 70 lmh. In other words, the higher the flux, the better the results. Moreover, the improved permeability lowers the number of membranes needed, lowering operations and maintenance (O&M) costs as well.

These five technologies represent a small but diverse sampling of what was showcased on the tradeshow floor. With the rate of desalination, brackish groundwater treatment, and reclamation and reuse all on the rise, membrane technology development — and the size of AMTA/AWWA — will surely trend up as well. Throughout the week’s proceedings, there was a palpable sense of potential, as if membranes are set to play a huge role in the future of water treatment.

I certainly wouldn’t bet against it.

What membrane applications have impressed you recently? What impact do you foresee for this technology going forward? Share your comments below…