Spiral Membranes: A Revolution In Water Treatment And Desalination

By Reports and Data

In the realm of advanced filtration technologies, spiral membranes have emerged as a revolutionary solution, transforming the landscape of various industries. These innovative membranes, characterized by their unique spiral-wound configuration, offer enhanced efficiency and versatility in separation processes. This article delves into the principles, applications, and advancements that make spiral membranes a cornerstone in the world of filtration.

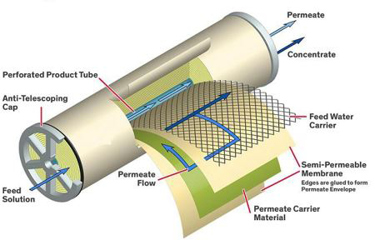

Understanding Spiral Membranes

Spiral membranes are a type of filtration membrane characterized by a spiral-wound design. This structure consists of a semi-permeable membrane material wrapped around a permeate collection tube, creating a spiral flow path. This arrangement maximizes the surface area available for filtration within a compact space, resulting in improved efficiency and reduced footprint compared to traditional flat-sheet membranes.

Spiral Membrane Market: Summary

The spiral membrane market was valued at USD 5.66 billion in 2022 and is expected to reach USD 11.60 billion in 2032, registering a CAGR of 8.3% during the forecast period.

These fabrics are unique materials that are used in the water and wastewater treatment, food and beverage, and the pharmaceutical and biotechnology industries for various purposes such as for filtration of chemicals, toxins, and many others.

The market for such membrane is influenced by the rising industries due to urbanization. Increasing use of such membranes, owing to growing awareness of wastewater treatment with the demand for selective separation in order to get better quality water is acting as a driving factor for this market. The stringent environmental regulations by governments in developing countries has propelled the market growth of such membranes. High expenses associated with the production of such membranes is one of the major restraints.

The factors mentioned above jointly create opportunities for the market growth, while factors such as critical effects of membrane manufacturing add limitations in the market. However, each element would have a specific impact on the market during the forecast period. Consistent developments in the market for membranes used for industrial purposes owing to innovative efforts have improved the efficiency of spiral membranes.

In the Asia Pacific region, due to the sudden rise in population and rapid urbanization, the market for such membranes is propelling at a swift rate. The rising economy in counties like China and Japan due to favorable political, social, and economic conditions are helping the market to grow. Chemical and petrochemical, food and beverage, and pharmaceutical industries of the APAC region are using these membranes for filtration purposes. China is the highest manufacturer and consumer of such fabrics.

Further Key Findings

- Water and wastewater treatment industries held the largest market share of 34.3% in the year 2018, due to growth in the economy and the shifting of population in developed countries in the urban areas. With a growing population and urbanization, the demand for clean water is also rising, which is benefiting the market growth of these membranes.

- The reverse osmosis segment is forecasted to witness the highest CAGR of 10.7% during the forecast period. This segment is rising since this technology is financially effective, advanced, and safe when compared to others. This technology is used both for industrial and municipal wastewater treatment.

- Polyamide polymer type segment held the largest market share of 44.8% in the year 2018. China became the largest consumer of this segment owing to the ever-growing food and beverage market, along with the textiles and chemical industries in this region because of growing urbanization and industrialization. China became a leader in the world for production and consumption of membrane products because of its low-cost labor, and the rise in urbanization with expanding economy compared with other countries.

- Asia Pacific region held the largest market share of 28.4% in the year 2018. Countries like India, China, Taiwan, Indonesia, and Japan are rapidly catching up with the growth in the spiral membrane market. The countries in this region have undertaken various measures towards water and waste treatment projects, which are propelling market growth.

- Key participants are Toray Industries, Inc., DowDuPont Inc., Hydranautics, SUEZ Water Technologies and Solutions, LG Water Solutions Koch Membrane Systems, Duraflow LLC, Pall Corporation, Pentair plc, and Lanxess, among others.

Benefits Of Spiral Membranes

Spiral membrane technology has revolutionized the field of separation processes, offering a myriad of advantages that make it a preferred choice in various industries. From water treatment to biotechnology, the unique design of spiral membranes has paved the way for enhanced efficiency, cost-effectiveness, and sustainability. Following are the key benefits that have propelled spiral membranes into the spotlight of advanced filtration technologies.

1. Compact Design and Space Efficiency

The spiral-wound configuration of membrane modules enables a high surface area within a relatively small footprint. This compact design is particularly advantageous in situations where space is limited, allowing for the installation of efficient filtration systems even in constrained environments.

2. Improved Filtration Efficiency

Spiral membranes provide a higher packing density compared to traditional flat-sheet membranes. The result is a more efficient use of membrane material, leading to enhanced filtration capacity and separation performance. This improved efficiency is crucial in applications where optimal separation is paramount.

3. Versatility in Applications

One of the standout features of spiral membranes is their versatility. These membranes find applications across diverse industries, including water treatment, wastewater management, pharmaceuticals, biotechnology, food and beverage, and more. Their adaptability to different filtration requirements underscores their significance in various processes.

4. Cost-effectiveness

The cost-effectiveness of spiral membrane technology is evident in several aspects. The efficient use of membrane material translates to reduced operating costs. Additionally, the compact design contributes to lower installation and maintenance expenses. As a result, industries can achieve high-performance filtration without breaking the bank.

5. Scalability and Modular Design

Spiral membrane systems are inherently scalable, allowing for easy customization based on the specific needs of a given application. The modular nature of these systems facilitates expansion or downsizing as requirements evolve, providing flexibility to industries with changing demands.

6. Energy Efficiency

The design of spiral membranes often allows for lower energy consumption in comparison to alternative filtration technologies. This is particularly crucial in industries where energy efficiency is a key consideration, contributing to both economic savings and reduced environmental impact.

7. Enhanced Fouling Resistance

Spiral membranes exhibit improved resistance to fouling, a common challenge in membrane-based separation processes. The spiral-wound structure, coupled with advanced materials and coatings, minimizes fouling and extends the lifespan of the membranes, resulting in more reliable and sustainable operations.

8. Sustainable Filtration Solutions

With a focus on resource conservation and sustainable practices, spiral membrane technology aligns with the growing global emphasis on eco-friendly solutions. Reduced waste generation, energy efficiency, and the ability to recover valuable resources from waste streams make spiral membranes a sustainable choice for modern industries.

Access free sample PDF here, and get detailed information here: https://www.reportsanddata.com/report-detail/spiral-membrane-market