Turnkey Bilge Water Purification Solutions Offered To Marine Ports

For the first time, marine ports have a bilge purification-system solution that delivers a totally reliable operation while reducing costs dramatically. BioPetroClean's new ACT technology for marine ports is fully-automated for hassle-free, non-technical operations, and fits perfectly into the pace and resources of a busy marine port.

Before international regulations were introduced to prevent oil pollution from ships, the standard practice for marine vessels was to wash out the contents of their tanks and release directly into the sea. The responsibility of cleaning this water has now fallen to the marine ports and port administrators.

"Bilge water is both a financial strain and an operational hassle. Problematic disposal of waste storage complicates a port administrator's tasks and can become an uninvited financial burden." said David Amir, CEO of BPC. By acquiring a total BPC turnkey solution, marine ports have an in-house solution for on-going treatment.

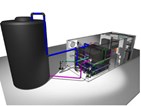

With only a one-time investment ports gain full control without the requirement of additional work force. With this skid-mounted, easy to integrate system installation is hassle free and fits even into the most limited spaces. The automated system provides port administrators and operators with automatic and upon-request reports at any desired time. It effectively monitors and balances the system to ensure clean water discharge is occurring.

What was once impossible is now in performance:

BPC's ACT system treats all categories, quantities, and levels of contaminates. It produces an output that can be directly returned to the sea – making it the ultimate green solution.

ACT system has been explicitly designed to perform at optimal levels when treating salt water, in direct contrast to other solutions whose performance degrades in the same conditions. BPC offers plug & play systems which handle 5-50 cubic meters an hour of water with an in-residence time of only 10 hours. BPC's ACT can also treat much higher capacities with custom-made solutions.

One-time service option:

There is a range of incidents in a marine port's routine that can cause a one-time crisis or large accumulation of bilge water to be treated. To get started BPC recommends its unique one-time ad hoc ACT service. With this simple option BPC analyzes the problem, treats with the appropriate custom engineering and bacterial solution, and discharges the water.

What is inside?

The key to ACT is assimilating the appropriate bacteria cocktail for each individual type of polluted water. By using the principle of chemostat, the process maintains a homeostatic state of bacterial growth and organic compound degradation. As a result the output can be deposited directly into the sea, meeting even the strictest environmental standards. BPC's patented technology delivers a beginning-to-end solution.

Water processed by gravitational separation is put into the bioreactor, where it is quickly and efficiently purified. When a change in parameters (organic levels, pH, etc.) occurs, the bioreactor's sensors communicate to the controller, automatically stabilizing the flow so that the balanced state is continuously maintained. The controller also issues on-line alerts to any chosen control center and/or designated supervisor. An extensive range of reports support a clear picture of operations at all times. This data, from technical performance to risk management, is automatically distributed on a "need to know" basis only.

About BPC

BPC directly addresses the challenges facing various industries and installations today: waste water treatment. Led by a world-respected scientist in biological treatments, BPC has developed a breakthrough balanced bio-process (ACT) that, for the first time, results in a virtually pure output that can be directly returned to nature. With several of its key technologies and elements patented, the BPC process transforms water treatment into a significantly more efficient, economical and ecologically friendly process. It can be applied across a wide range of sites: from oil refineries and oil storage farms to drilling sites, marine ports, side streams water, reservoirs and similar locations.

For further information visit: www.biopetroclean.com

SOURCE: BPC