Sidestream Enhanced Biological Phosphorus Removal Made Easier

By Leon Downing, James Barnard, And Patrick Dunlap

Some excellent progress has been made in recent years on sidestream enhanced biologic phosphorus removal, but a current project promises to advance the practice even further.

A Water Research Foundation (WRF) project launched in 2019 is taking a deeper dive into sidestream enhanced biologic phosphorus removal (S2EBPR). Led by Black & Veatch and Cornell University and executed by a large team of consultants and utilities, WRF 4975 will yield guidelines for the design, operation, and implementation of a unique configuration to help remove phosphorus from U.S. waterways.

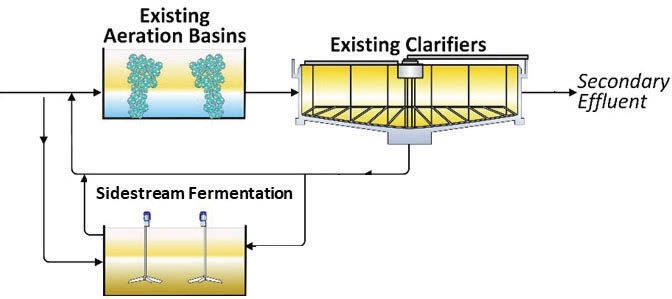

Sidestream enhanced biological phosphorus removal achieves biological phosphorus removal in a sidestream fermentation tank. The process can improve stability, simplify construction, and minimize impacts on existing infrastructure.

What’s Behind This?

S2EBPR is the current stage in the evolution of biological phosphorus-removal understanding. For nearly half a century, the industry has sought to remove phosphorus from our waterways to decrease algae growth and protect human health and the environment. In the 1970s, Black & Veatch’s James Barnard led the global effort to develop biological processes for phosphorus removal. Enhanced biological phosphorus removal (EBPR) is the process that removes phosphorus microbiologically in activated sludge systems. Historically, EBPR processes relied on an unaerated zone at the influent side of the activated sludge processes to produce the environment favorable to selection of phosphate-accumulating organisms (PAOs). These PAOs take up phosphorus into biomass, removing the phosphorus from liquid discharges to surface waters.

Although EBPR processes offer advantages compared to chemical phosphorus removal, they can require standby chemicals to achieve reliable and consistent performance. Over the past 10 to 15 years, the water industry has learned that diverting a portion of the biomass from activated sludge to a sidestream reactor produces fermentative conditions, which can produce a more diverse EBPR microbiome and increase removal performance and stability. The core S2EBPR configurations rely on sidestream fermentation to select for a more diverse microbiome.

The movement to sidestream fermentation has produced potential for more stable operation and reduced construction complexity when converting to biological phosphorus removal. But several facilities have found that decreased mixing in mainstream anaerobic zones can also result in a selective pressure and fermentative conditions to improve biological phosphorus removal. This important leap in the evolution of EBPR results in more stable removal of phosphorus.

Why Now?

DNA sequencing, new modeling approaches, and new and emerging process technologies have provided greater understanding of the mechanisms for phosphorus removal in the activated sludge process, both chemically and biologically. Plant owners and operators want to put these new insights to work right away, instead of waiting many years to change how they take advantage of the industry’s deeper understanding.

One of the main drivers for this research is to capture information generated by facilities and studies globally, consolidate the information, and develop definitive recommendations for design and conclusions about the mechanisms of biological phosphorus removal. Facilities in Denmark and Sweden have been implementing full-scale S2EBPR for more than a decade, and pieces of information are sprinkled around the world. Several facilities in North America have experimented with S2EBPR concepts for the past five years, and much academic literature about the microbiology of phosphorus removal has been published over the past several decades. But there is no consolidated, standard approach to application of S2EBPR. Nor is there a manual for how to design and operate S2EBPR facilities. Individual facility owners have had to pilot, demonstrate, and try to figure out what works for their own treatment plants. That’s something that the project leaders, core team, and collaborative partners expect to change.

WRF Project UR13, led by April Gu from Cornell University, helped consolidate some of the available information, but no one has comprehensively collected this information and established guidelines to help ensure that S2EBPR is properly applied. WRF 4975 will build from that research to help utilities better understand what works well and why.

How Will it Unfold?

As part of this project, the research team will establish design guidelines, develop operational tools, and recommend best practices for modeling.

Design guidelines. The design guidelines will focus on developing a clear, consolidated picture of how much return activated sludge (RAS) biomass to divert to the sidestream reactor. The design guidelines will address questions such as “How long should that hydraulic retention time be?”, “How do you mix the biomass in the reactor?”, and “What are the key indicators that it is working?” Currently, some facilities divert 10 percent of their RAS biomass to sidestream fermentation tanks while others divert 30 percent, and some have a 12-hour hydraulic retention time (HRT) while others have a 36-hour HRT. All these facilities work, but the industry needs to understand why they’re different to identify optimal design practice. Narrowing the current large bandwidth of design parameters will make design and implementation more efficient. That’s the first objective.

Operational tools. The development of operational tools builds upon the research completed by Gu at Cornell University, which examined many DNA-based tools. The team will seek to better understand the bacteria and determine how these tools might be better used. In addition to advanced DNA tools, the team will explore kinetic rate-testing protocols and practices and identify best practices for application of these tests for evaluation, design, and operation.

Drawing from the experience of the Metro Wastewater Reclamation District in Denver and nine other utility participants now actively testing S2EBPR configurations will help the WRF 4975 research team simplify the application of sidestream enhanced biological phosphorus removal by others.

Modeling. Process modeling is a huge part of our design industry. It helps us understand what’s going on inside the process. The industry needs answers about whether we are simulating phosphorus removal correctly and guidelines for how to best implement our current model structures to predict phosphorus-removal performance.

What Will Be Produced For The Industry?

A team of leading utilities, academic experts, and consulting partners will collaboratively develop the practical tools by analyzing large data sets to draw usable conclusions. The core team, which consists of experts from Black & Veatch and several other academic and consulting entities, will collect information from myriad sources and establish consistency in testing and data interpretation.

Nineteen utilities — 10 of which are actively testing S2EBPR configurations now — are also participating in this research project. Facilities range in size from 1 MGD to 350 MGD, and the largest facility has a 50-MGD pilot reactor.

The goal is to produce intermediate deliverables to get this information out to the industry as quickly as possible. The overall project will take two and a half years to complete. But disseminating information as it becomes available will help utilities and others apply and benefit from this research sooner rather than later.

About The Authors

Leon Downing, PhD, PE, is the principal investigator for WRF 4975 and an expert in resource recovery design and modeling. In his role as principal process and innovation leader of Black & Veatch’s Water Technology Group, Downing provides technology leadership and client-focused process engineering support for Black & Veatch projects globally. He has also guided and assisted in major resource-recovery projects across the globe.

Leon Downing, PhD, PE, is the principal investigator for WRF 4975 and an expert in resource recovery design and modeling. In his role as principal process and innovation leader of Black & Veatch’s Water Technology Group, Downing provides technology leadership and client-focused process engineering support for Black & Veatch projects globally. He has also guided and assisted in major resource-recovery projects across the globe.

James Barnard, PhD, D.Ing h.c., P.Eng, BCEE, is leading the Technical Advisors for WRF 4975 and is a Global Practice and Technology Leader for Advanced Biological Treatment at Black & Veatch. Barnard is credited for formalizing many treatment processes involving biological nutrient removal and for developing the original Bardenpho (Barnard Denitrification and Phosphorus Removal) and Phoredox processes. His advances in nutrient management include the development of S2EBPR.

James Barnard, PhD, D.Ing h.c., P.Eng, BCEE, is leading the Technical Advisors for WRF 4975 and is a Global Practice and Technology Leader for Advanced Biological Treatment at Black & Veatch. Barnard is credited for formalizing many treatment processes involving biological nutrient removal and for developing the original Bardenpho (Barnard Denitrification and Phosphorus Removal) and Phoredox processes. His advances in nutrient management include the development of S2EBPR.

Patrick Dunlap, PE, is a lead researcher for WRF 4975 and a process engineer in Black & Veatch’s Water Technology Group. He focuses on the application of process modeling for design and operation of water resource recovery facilities. Dunlap’s EBPR expertise includes special emphasis on the application of process modeling to better understand the biological mechanisms of phosphorus removal.

Patrick Dunlap, PE, is a lead researcher for WRF 4975 and a process engineer in Black & Veatch’s Water Technology Group. He focuses on the application of process modeling for design and operation of water resource recovery facilities. Dunlap’s EBPR expertise includes special emphasis on the application of process modeling to better understand the biological mechanisms of phosphorus removal.