Seattle Public Utilities Case Study: Using A Business Case Evaluation To Identify The Most Desirable Rehabilitation Outcome

By Barbara Swartz and Carita Parks

A recently published WERF report, Flood Grouting for Infiltration Reduction on Private Side Sewers (INFR5R11), provides results of a field test of the flood grouting process to seal laterals, sewer mains, and manholes. Prior to obtaining approval to proceed with this pilot project, a “business case” was prepared to compare the total life-cycle cost of the proposed option to other alternatives, which included joint grouting, pipe bursting, cast-in-place pipe (CIPP) lining, and replacement with upsized pipe. The amount of flow reduction was measured and compared that to the total project costs as tracked through Seattle Public Utilities’ cost accounting system. Researchers looked at the potential for using the technology to reduce the risk for future backups in Seattle’s Broadview neighborhood, as well as its applicability in other locations.

The Broadview neighborhood has a 1950s-era concrete pipe sanitary sewer system that has experienced repeated wet weather sanitary sewer overflows from both manholes and into basements during extreme storm events. Over time, the pipes have deteriorated, allowing excessive amounts of infiltration through separated joints, fractures, and other defects. As a result, Seattle Public Utilities (SPU) undertook a project to address two poorly understood aspects of sewer rehabilitation:

- An intensive asset management-based evaluation process known as a business case evaluation (BCE).

- Evaluation of the cost-effectiveness of an innovative sewer rehabilitation process on a large targeted area.

As sewer collection systems age and deteriorate, infiltration of groundwater into mainlines as well as lateral or side sewers increases. Municipalities interested in reducing wet weather flows have limited options; primarily, these efforts are limited to structural repairs or replacement. Often the pipes are in satisfactory structural condition, yet only structural rehabilitation methods are available. Point grouting of isolated points has been conducted for some time with varying degrees of success. SPU looked to an innovative non-structural solution known as flood grouting. Flood grouting is aimed at stopping infiltration into sewers by simultaneously sealing large portions of a system, including maintenance holes, sewer mains, and laterals located within the public right-of-way and on private property.

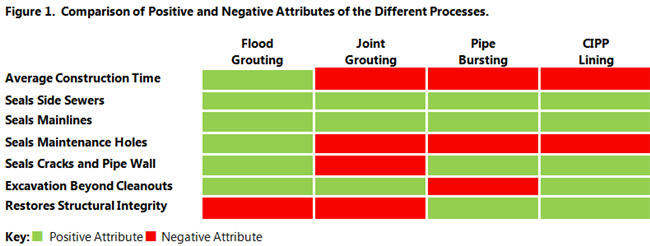

This BCE was conducted to identify a preferred alternative and to validate the technology. Before settling on flood grouting, SPU identified four possible rehabilitation processes (flood grouting, joint grouting, pipe bursting, and cast-in-place pipe (CIPP) lining). Cost estimates for each of the methods were developed and these costs were then compared to the benefits of completing the project. Some of the benefits included reduced claims, reduced storage costs at a regional wet weather treatment facility, reduced conveyance and treatment costs, and installing cleanouts on side sewers and inspecting privately held sewer assets. The intrinsic benefits of each process were examined in relation to the benefit/cost comparison of the various methods (See Figure 1). This process identified flood grouting as having the greatest benefit cost ratio of all the options and it was selected as the preferred alternative for the infiltration reduction project.

Gaining Public Acceptance is Critical

One of the perceived risks of using this new technology was public acceptance of the project. In order to seal side sewers, cleanouts had to be installed on each side sewer, close to each house, which required a signed right-of-entry from the homeowner. Seattle had never done projects that addressed privately owned side sewers. Therefore, it was necessary that the affected citizens felt that the benefits of the project would outweigh any risks before they agreed. Success of the project depended on both addressing community concerns and effectively implementing a variety of outreach strategies. Contact with residents was made through a mailed introduction letter, public presentation, another mailing with right-of-entry information, phone calls, certified mailings, and an open house at the installation site. In the end, SPU obtained a 95% sign-up rate.

Pilot Site Installation

Once SPU received a significant number of right-of-entry forms from homeowners, inspection and installation of the cleanouts began. Following inspection, the cleanouts were installed at the locations identified by the internal inspection. The cleanouts were installed by the Vac-A-Tee method, a minimally invasive process that utilizes a vacuum to expose the side sewer to determine where a new riser pipe can be attached. The flood grouting process began with a pre-cleaning of the manholes, mainlines, and side sewers. Next, plugs were installed in upstream and downstream manholes in the mainline pipe and side sewers through the newly installed cleanouts. Once all the plugs were installed, the two chemicals were introduced into the system.

Conclusions

The Sanipor flood grouting technology was applied to a 31-acre residential sub-basin in the Broadview neighborhood of Seattle. All of the manholes and mainlines were sealed; however, only 30% of the total side sewer length could be accessed for sealing due to several reasons, including multiple side sewer branches on each house, landscaping, elevation differences, and homeowner approval of the cleanout location. Approximately 56% of the entire sewer basin was sealed. Based on measured exfiltration rates of the flood grouting chemicals, the sections that were sealed had a 99% improvement in their exfiltration rates.

The project was considered a success from several perspectives and can serve as an example of how to introduce and implement a new technology to solve an old problem. By using a business case evaluation, SPU was able to determine which rehabilitation option would provide the best results and in the most effective means. Flood grouting proved to be successful in reducing infiltration with relatively little disruption to the community and at a potentially lower cost than the other technologies. Additionally, with an effective public outreach plan, gaining access to private side sewers was an achievable component that was necessary to attain maximum infiltration reduction.

SOURCE: Water Environment Research Foundation